Rolling mechanism of aluminium-strip winding machine

A technology of winding machine and rolling, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., and can solve problems such as unfavorable packaging and transportation, loose metal strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

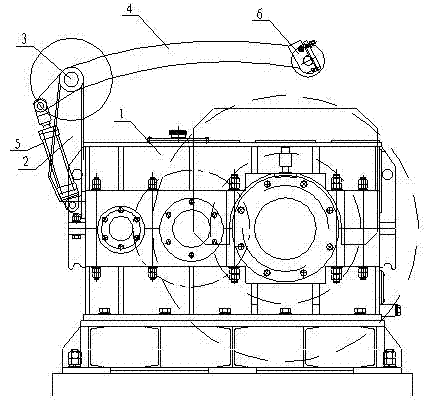

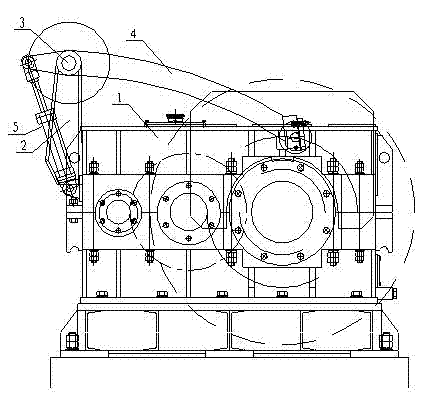

[0014] like Figure 1-2 As shown, the rolling mechanism of the aluminum strip winder according to the embodiment of the present invention includes a support frame 2 fixed on the side of the winder housing 1, and the support frame 2 is installed vertically. The top is provided with a support roller shaft 3, and a pressing arm 4 is installed on the support roller shaft 3, and a telescopic oil cylinder 5 is provided at the bottom of the support frame 2, and a torsion is adopted between the cylinder liner of the telescopic oil cylinder 5 and the support frame 2. Connected, the cylinder rod of the telescopic oil cylinder 5 is hinged with one end of the pressing arm 4, and the other end of the pressing arm 4 is equipped with a pressing roller 6.

[0015] The support frame 2 is fixed on the side of the winding machine housing by screws.

[0016] The upper part of the support frame 2 is triangular in shape.

[0017] The press roller 4 is installed on the press roller shaft on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com