Ejection mechanism and electric connector utilizing same

A technology of electrical connectors and driving mechanisms, which is applied in the direction of connection and connection of parts and circuits of devices, and can solve the problems that electrical connectors cannot be separated quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

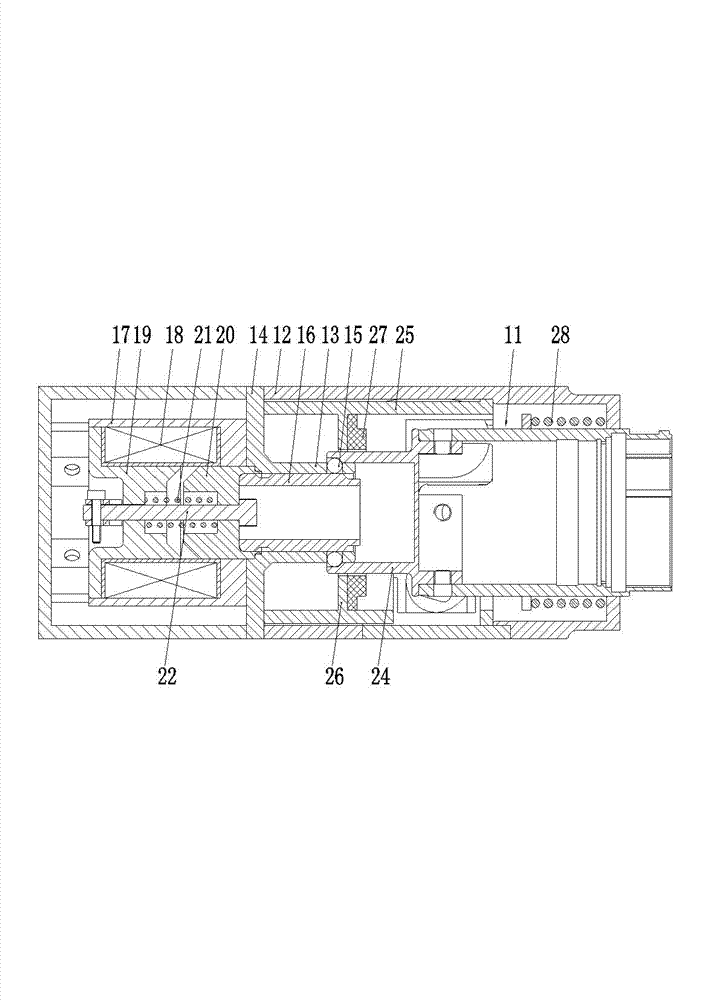

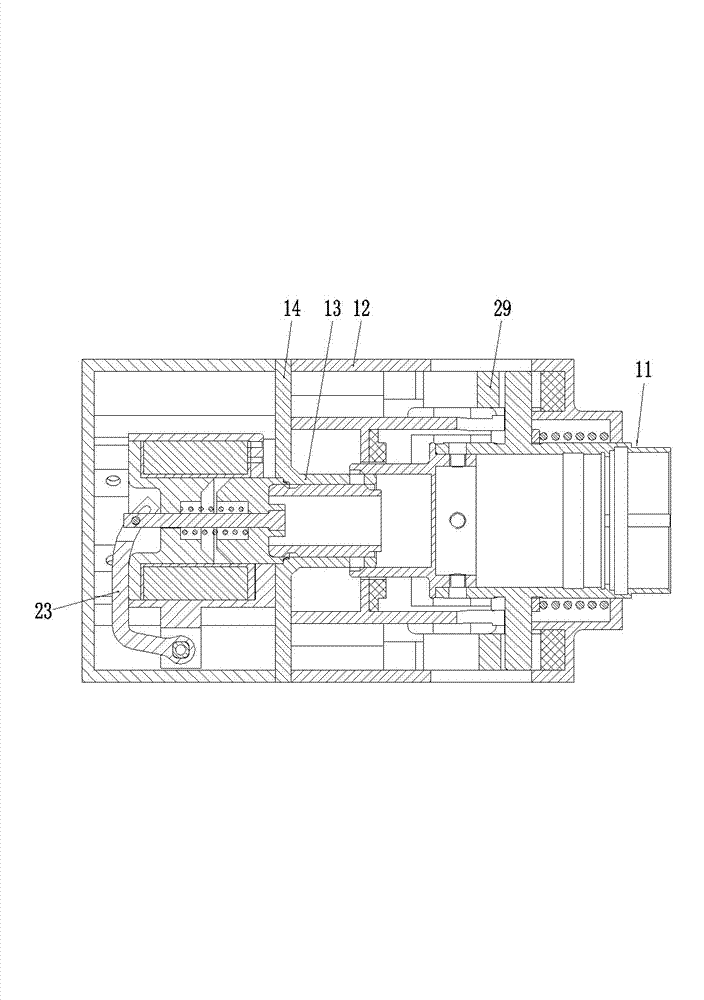

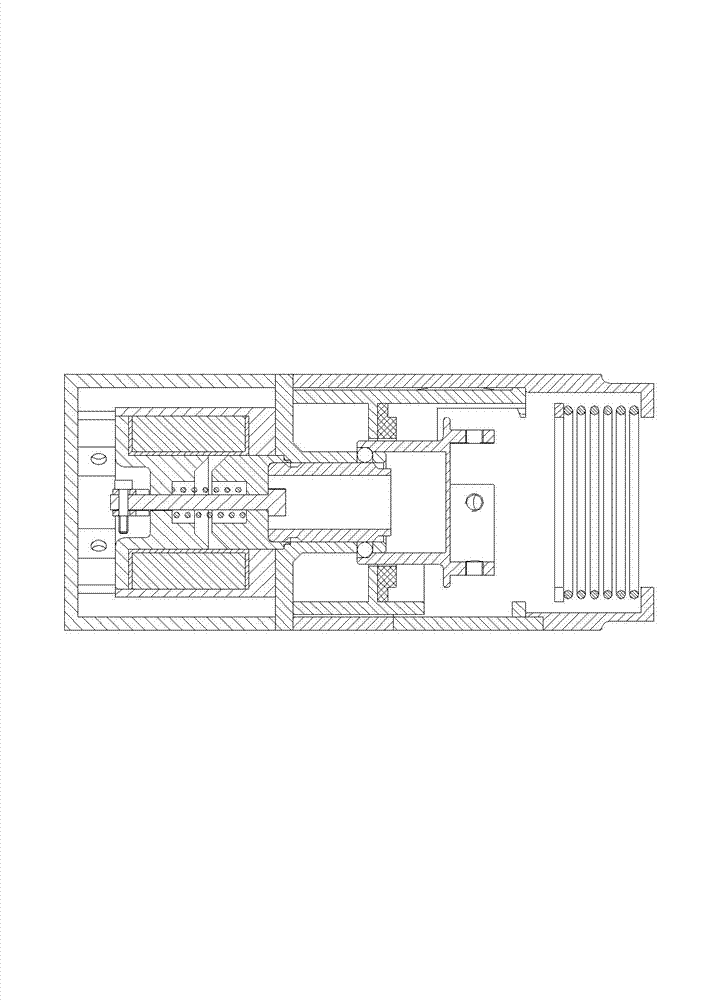

[0020] Embodiment 1 of the electrical connector of the present invention, such as Figure 1-2 As shown, it includes an electrical connector body 11 and an ejection mechanism. The ejection mechanism includes a housing 12. The housing 12 is a split structure and includes a front half and a rear half connected by screws. The housing 12 has a mounting channel extending in the front-to-rear direction, and the mounting channel is provided with a front-to-rear direction extending The fixing sleeve 13 has a mounting plate 14 formed at the rear of the fixing sleeve 13 diverging and extending radially outwards. The mounting plate 14 is fixed between the front half and the back half of the housing 12, and the fixing sleeve 13 passes through the mounting plate. 14 is fixed in the installation channel of the shell; in addition, the front wall of the fixing sleeve 13 is provided with a steel ball hole which is transparent inside and outside, and a steel ball 15 is assembled in the steel ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com