heat exchange equipment

一种热交换设备、热传递的技术,应用在热交换设备、蓄热设备、照明和加热设备等方向,能够解决热交换器贮热能力不足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

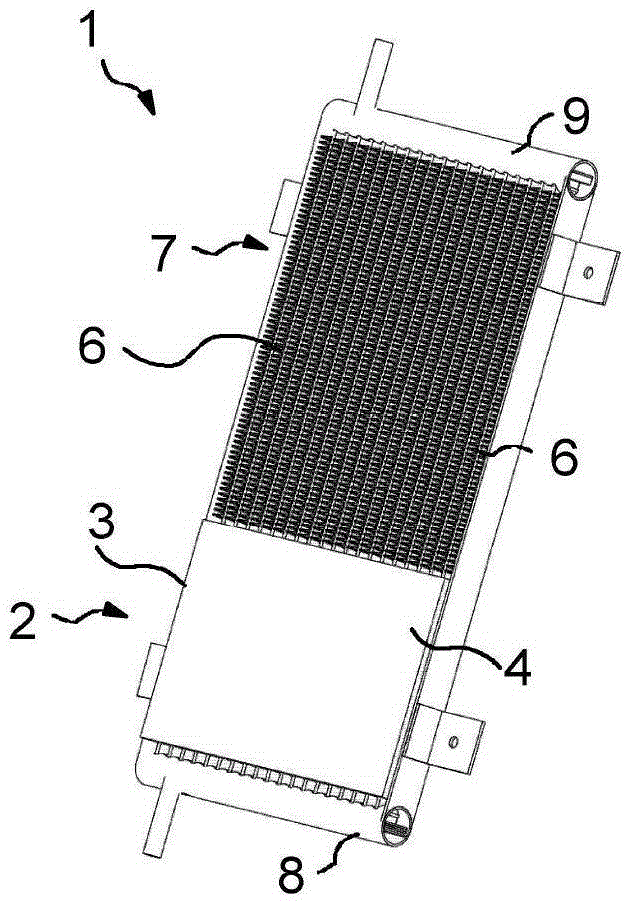

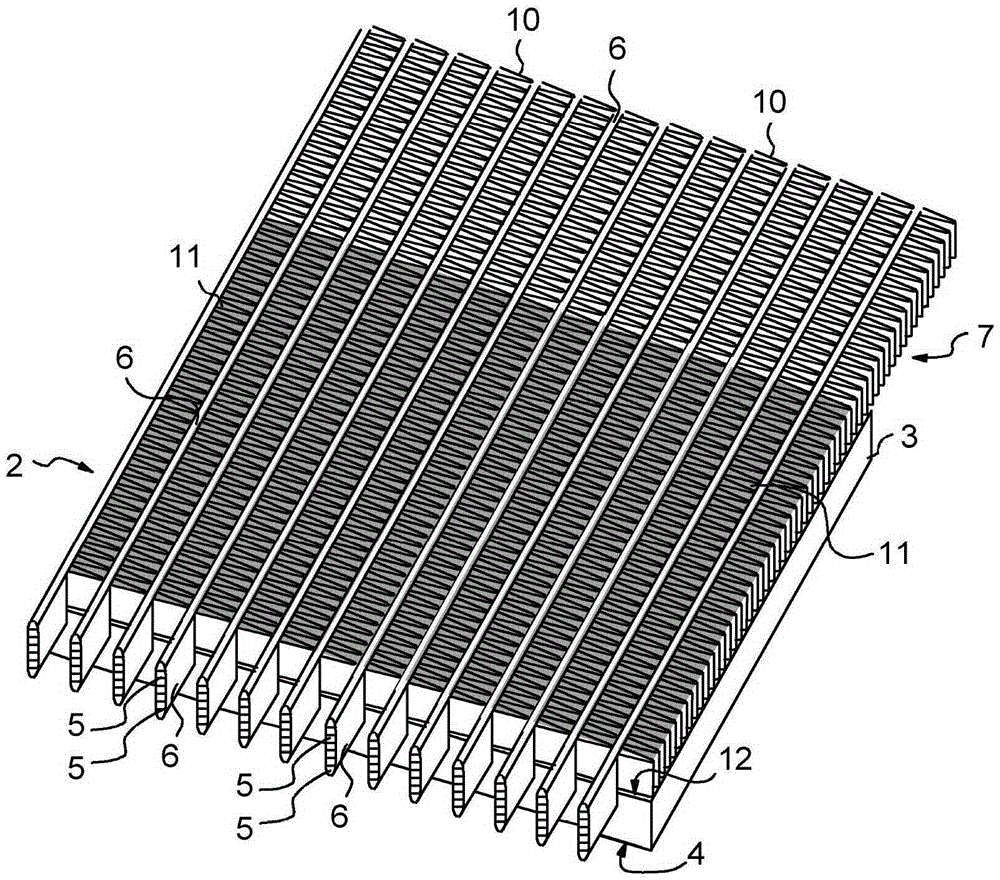

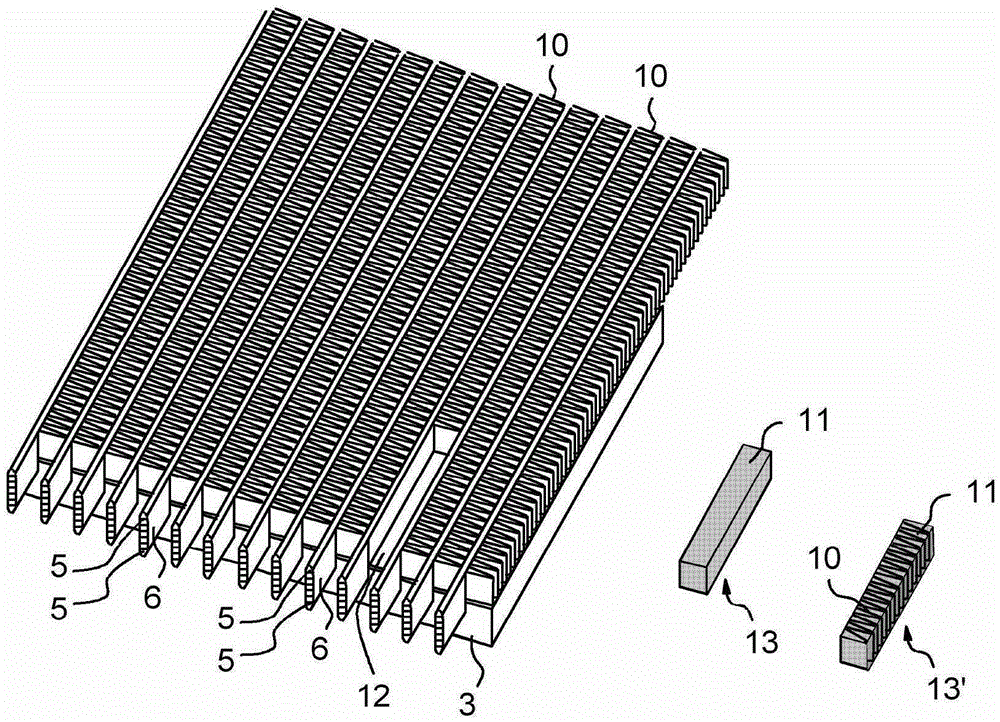

[0013] Figures 1 to 2 A first embodiment of the device 1 is depicted. The device comprises a first heat transfer element 2 comprising a base plate 3 having a first surface 4 for receiving one or more electrical components which require cooling during their use to avoid temperatures overly elevated. The first heat transfer element 2 also comprises a plurality of channels 5 for transferring the received heat load into a fluid circulating in said channels. From figure 2 As can be seen in the figure, in this embodiment the channels 5 are arranged in a duct 6 which is spaced apart and has an inner wall separating the plurality of channels 5 from each other. The pipe may be an MPE (Multiple Extruded) pipe, made eg by extruding aluminium. exist figure 1 In , the device 1 is observed along the direction that the substrate 3 is at the top of the pipe 6, while figure 2 Only some parts of the device 1 are depicted in the direction in which the pipe 6 is located on top of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com