industrial vehicle

A technology for industrial vehicles and vehicles, applied in the direction of lifting devices, etc., can solve the problems of difficult visual confirmation of vehicles and entry, and achieve the effect of saving installation labor and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

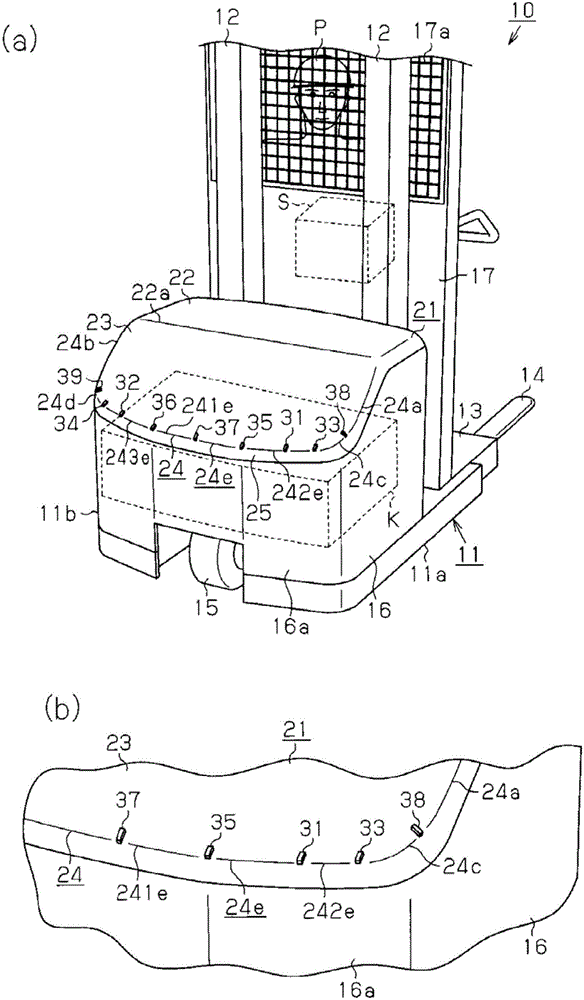

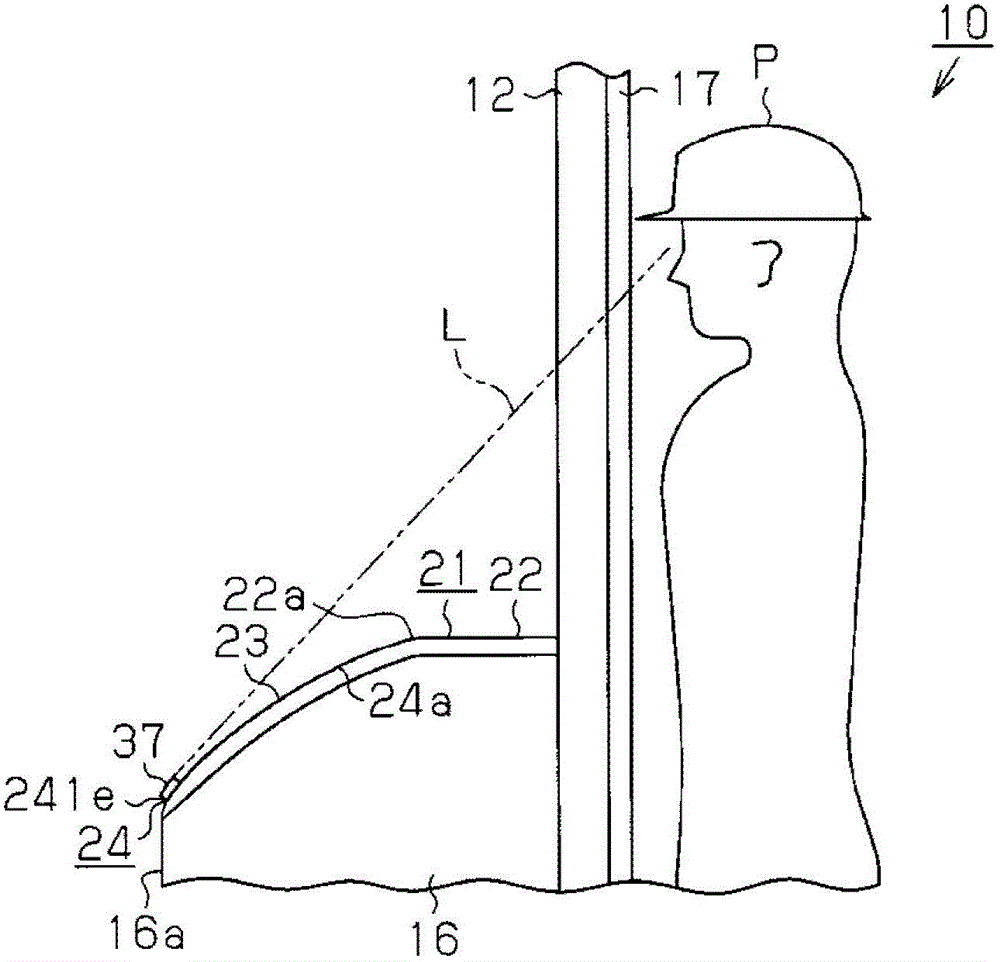

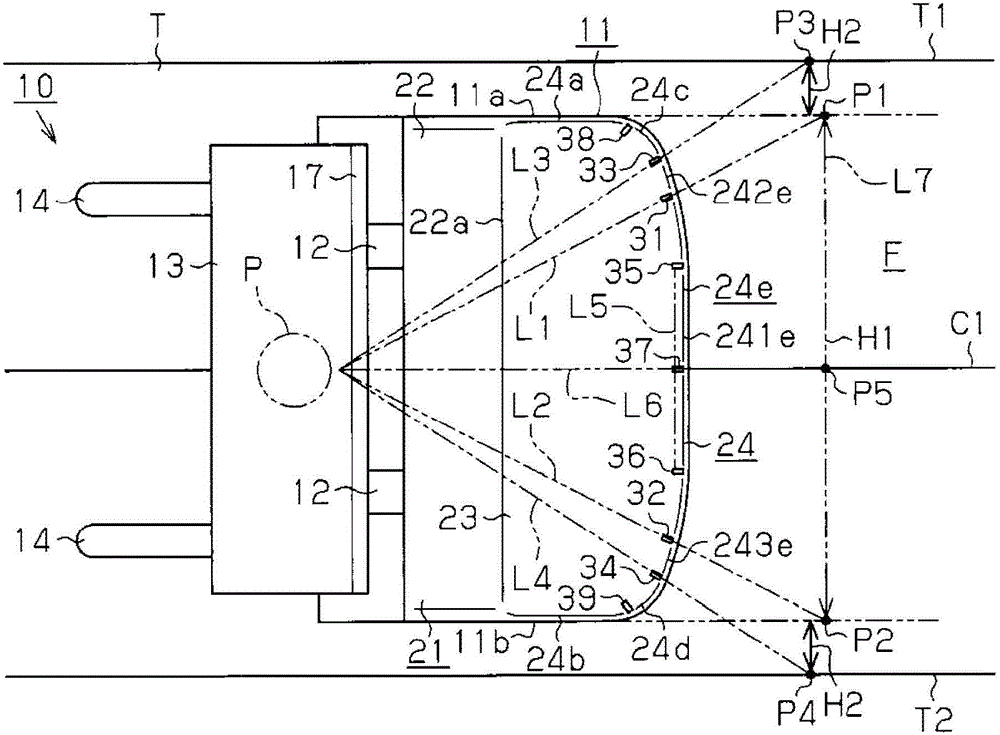

[0031] Below, according to Figure 1 ~ Figure 3 An embodiment in which the present invention is embodied in a picking cart will be described. In the following descriptions, "front", "rear", "left", "right", "up", "down", show that the driver (worker) of the picking vehicle faces the front of the picking vehicle (forward). Direction) state is "Front", "Back", "Left", "Right", "Up", "Down" at the reference time. Also, let the left-right direction of the picking vehicle be the vehicle width direction.

[0032] Such as figure 1As shown in (a), a pair of door frames 12 are erected on the vehicle body 11 of the picking vehicle 10 . A workbench 13 is provided in front of the pair of door frames 12 . A table 13 is supported by a pair of door frames 12 so as to be able to move up and down. A fork 14 serving as a cargo handling tool for cargo loading and unloading work is fixed to the front portion of the workbench 13 . A rear panel 17 is erected at the rear of the workbench 13 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com