Suppressing method for loading rollers at height

A wire-mounted roll and high-pressure cavity technology, applied in metal rolling, metal rolling stands, manufacturing tools, etc., can solve the problems of high price of tungsten carbide roll rings, high roll explosion rate, and large losses, and achieve feasibility and The effect of strong generalization, low burst rate and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

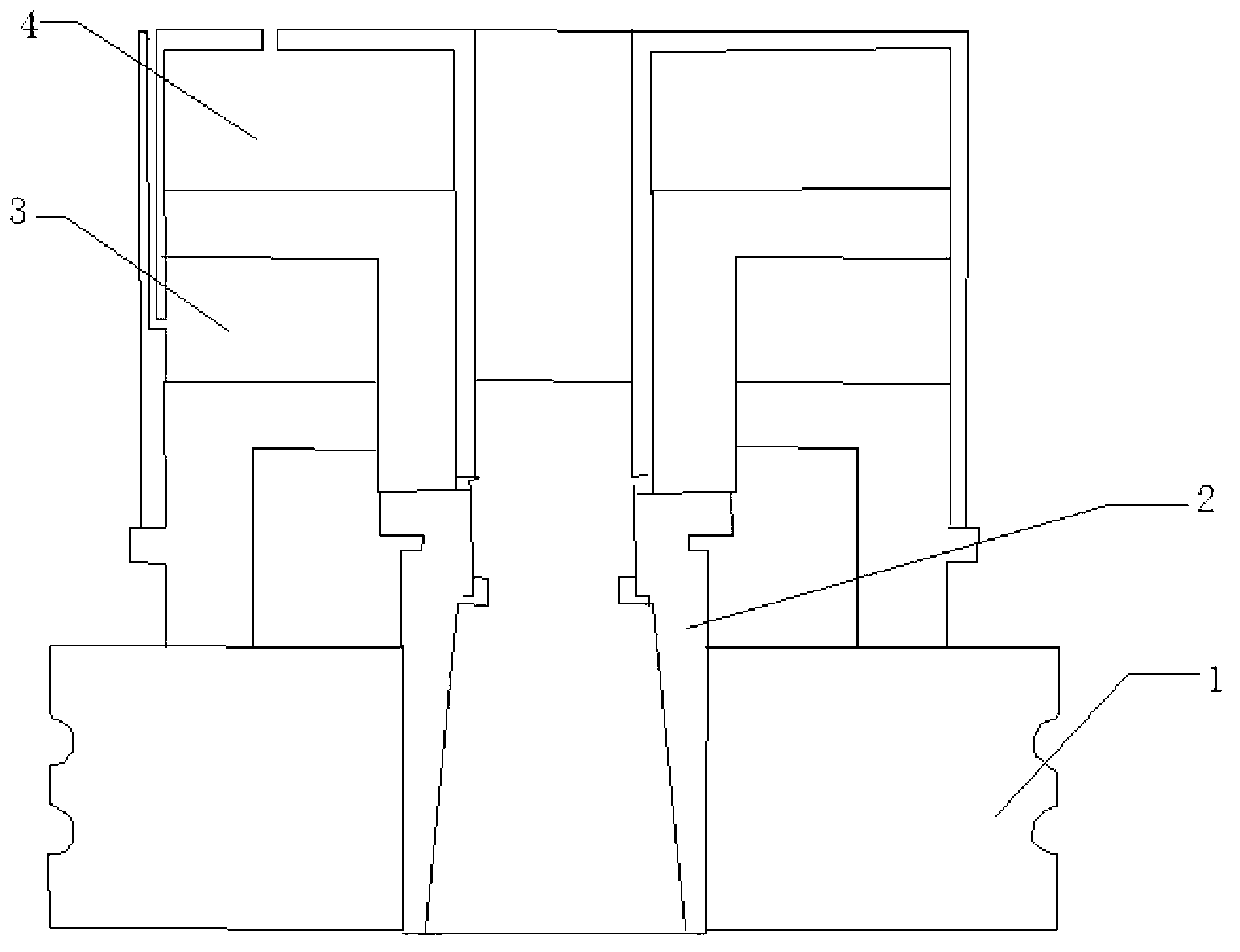

[0014] A kind of pressing method of high-line loading roller provided in this embodiment, the structure of its realization device is as follows: figure 1 As shown, the method includes the first pressing and the second pressing.

[0015] The first crackdown includes the following steps:

[0016] (1) The pressing trolley delivers a low pressure of 15-18Mpa to the low-pressure cavity 3, and exerts pressure on the roller ring 1 to make the roller ring 1 fall in place.

[0017] (2) The pressing trolley delivers a high pressure of 45Mpa to the high-pressure cavity 4, and presses the taper sleeve 2 to make the taper sleeve 2 in place.

[0018] (3) After the pressure in the low-pressure chamber 3 and the high-pressure chamber 4 is reset to zero, the low pressure is sent to the low-pressure chamber 3 again to reset the inner cylinder.

[0019] Pressing for the second time is to carry out the counter-beating operation. The operation method is as follows: when the low pressure is zero,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com