Rectangular stirring pile-forming machine

A pile machine, rectangular technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as small overlap area and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

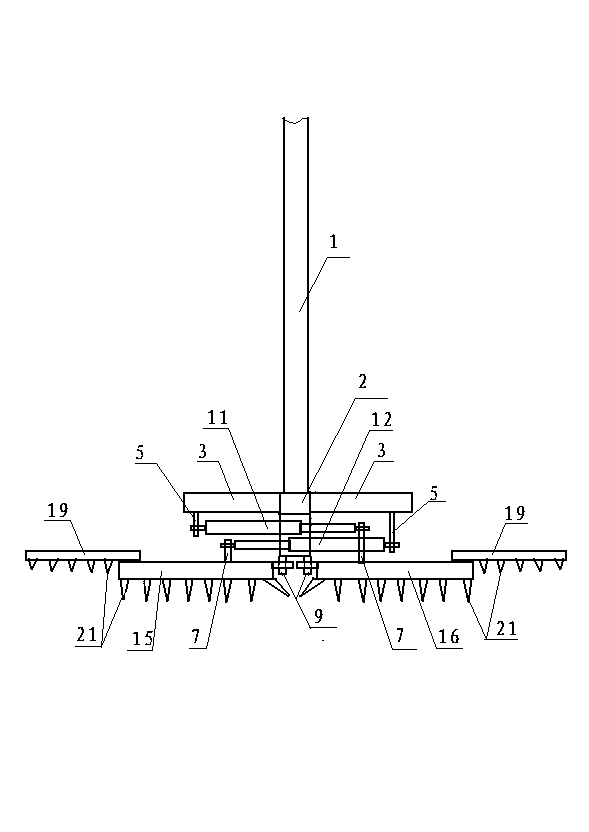

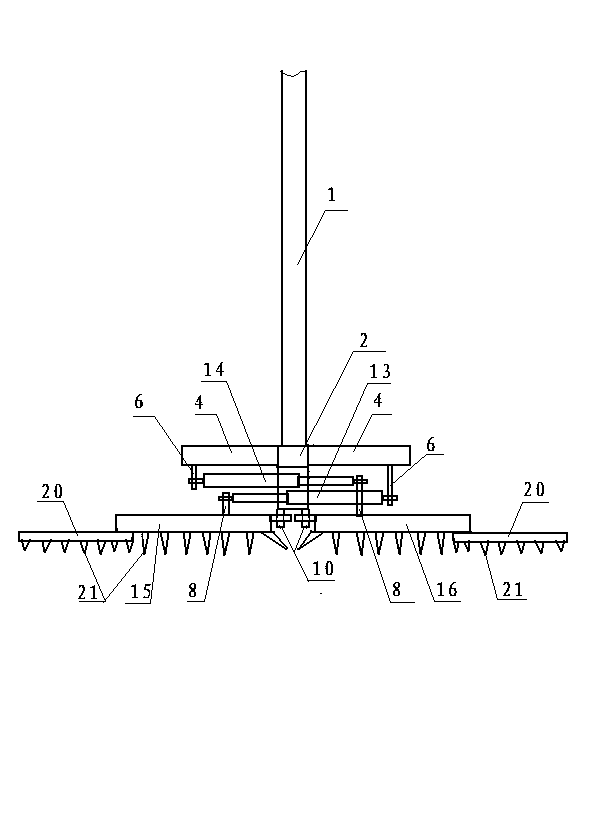

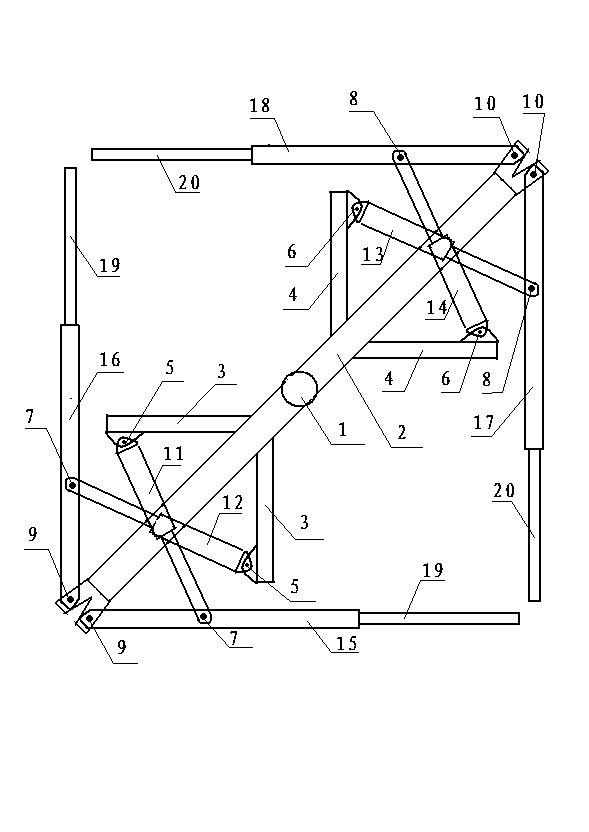

[0013] The accompanying drawing is a specific embodiment of the present invention. In this embodiment, the lower end of the drill pipe 1 is fixed in the middle of the beam 2. Two pivot pins F9 are arranged side by side at one end of the beam. One end of the knife arm A15 is pinned to a pivot pin F9. The upper part of the other end of A is fixed with a secondary knife arm A, one end of the knife arm B16 is pinned to another pivot pin F9, the other end of the knife arm B is fixed with a secondary knife arm A19, and the other end of the beam is arranged side by side with two pivot pins H10. One end of arm C is pinned to a pivot pin H10, the lower part of the other end of arm C is fixed with slave arm B, one end of arm D is pinned to another pivot pin H10, and the lower part of the other end of arm D is fixed with slave arm B20; Two support frames A are fixed on the beam on one side of the drill pipe. One end of the driving cylinder A11 is pinned to the support frame A through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com