Ceramic riveting die with conductive core

A technology of riveting and ceramic materials, which is applied in the direction of gear transmission mechanism, clutch, mechanical drive clutch, etc., can solve the problems of wrong information, wrong riveting structure, etc., and achieve the effect of improving sensing accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The drawings are only schematic and are used only for the understanding of the invention. Identical elements are provided with the same reference numerals.

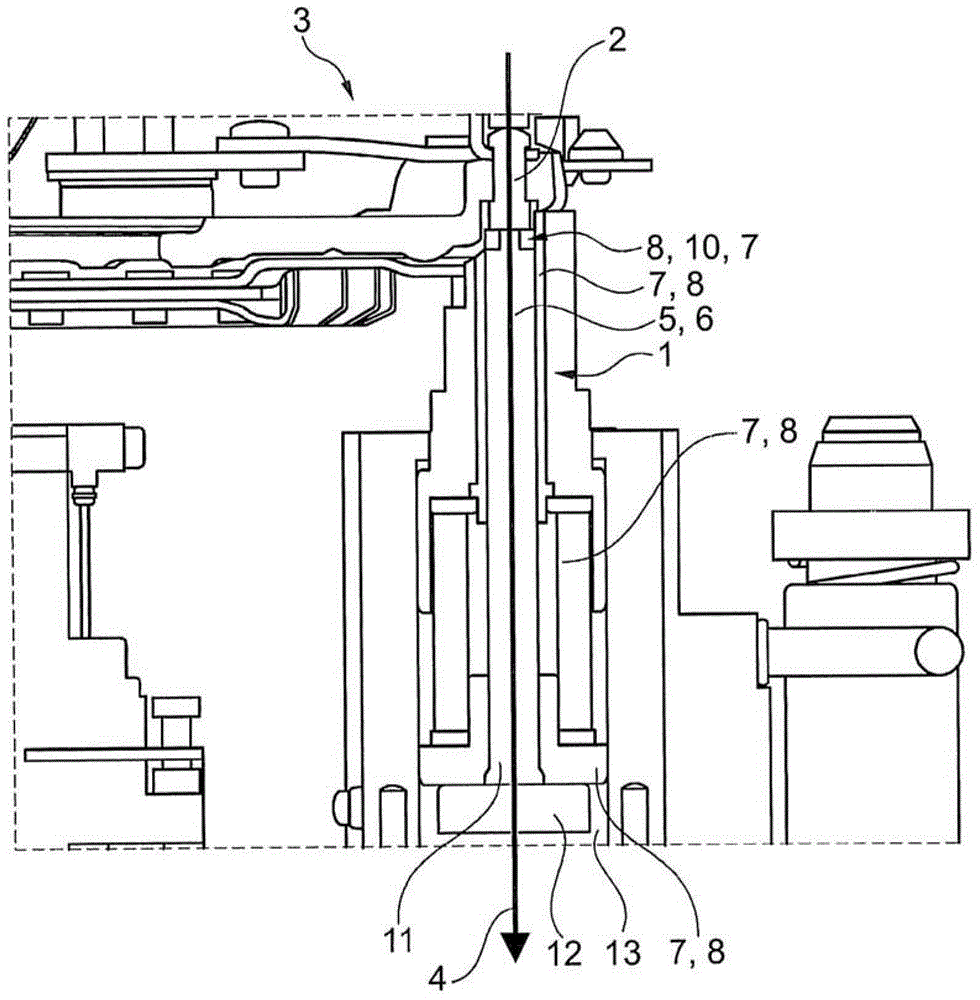

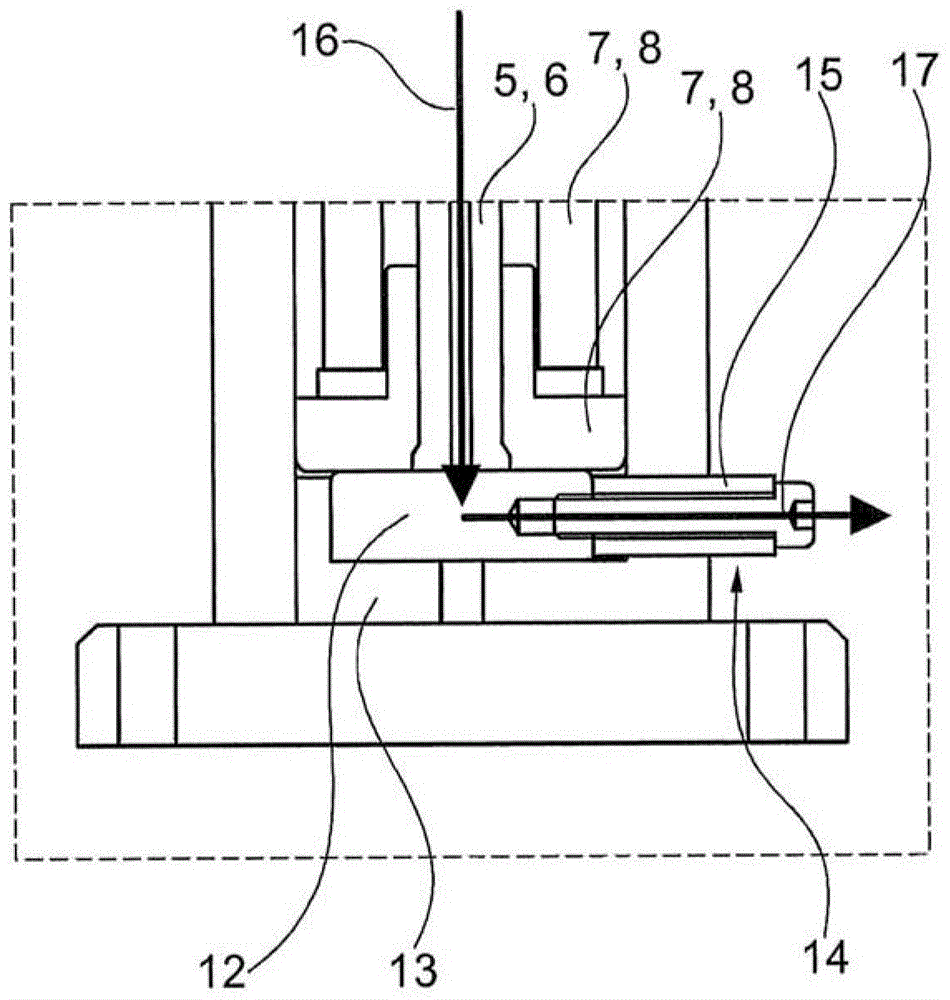

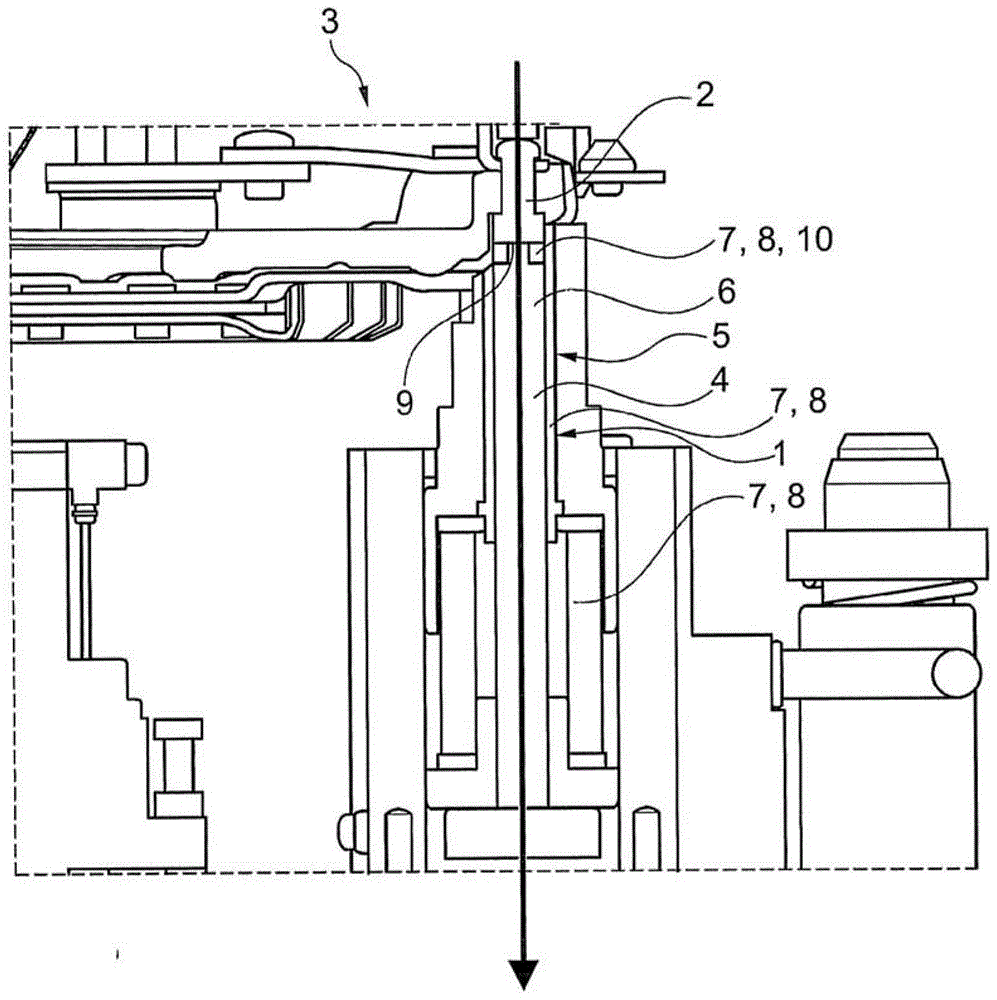

[0037] figure 1 A first embodiment of a riveting punch 1 according to the invention is shown for riveting a rivet 2 to a clutch, such as a double clutch 3 . However, the riveting die 1 can also be used when riveting lever actuators or dual mass flywheels.

[0038] The riveting die 1 is elongated and extends along a longitudinal axis 4 . Its body 5 has an electrically conductive core 6 surrounded by an electrically insulating cover layer 7 . The electrically insulating cover layer 7 acts as an insulation. It is divided into a plurality of insulating sections 8 .

[0039] An insulating end piece 10 is provided on the end 9 of the riveting die 1 adjacent to the rivet. The insulating end piece 10 is annular and made of ceramic. The core 6 of the riveting die 1 is also made of ceramics. Of course, the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com