Tensioning wheel

A technology of tensioning pulley and wheel body, applied in the direction of belt/chain/gear, label, packaging, etc., can solve the problem of belt slipping and affecting the operation of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

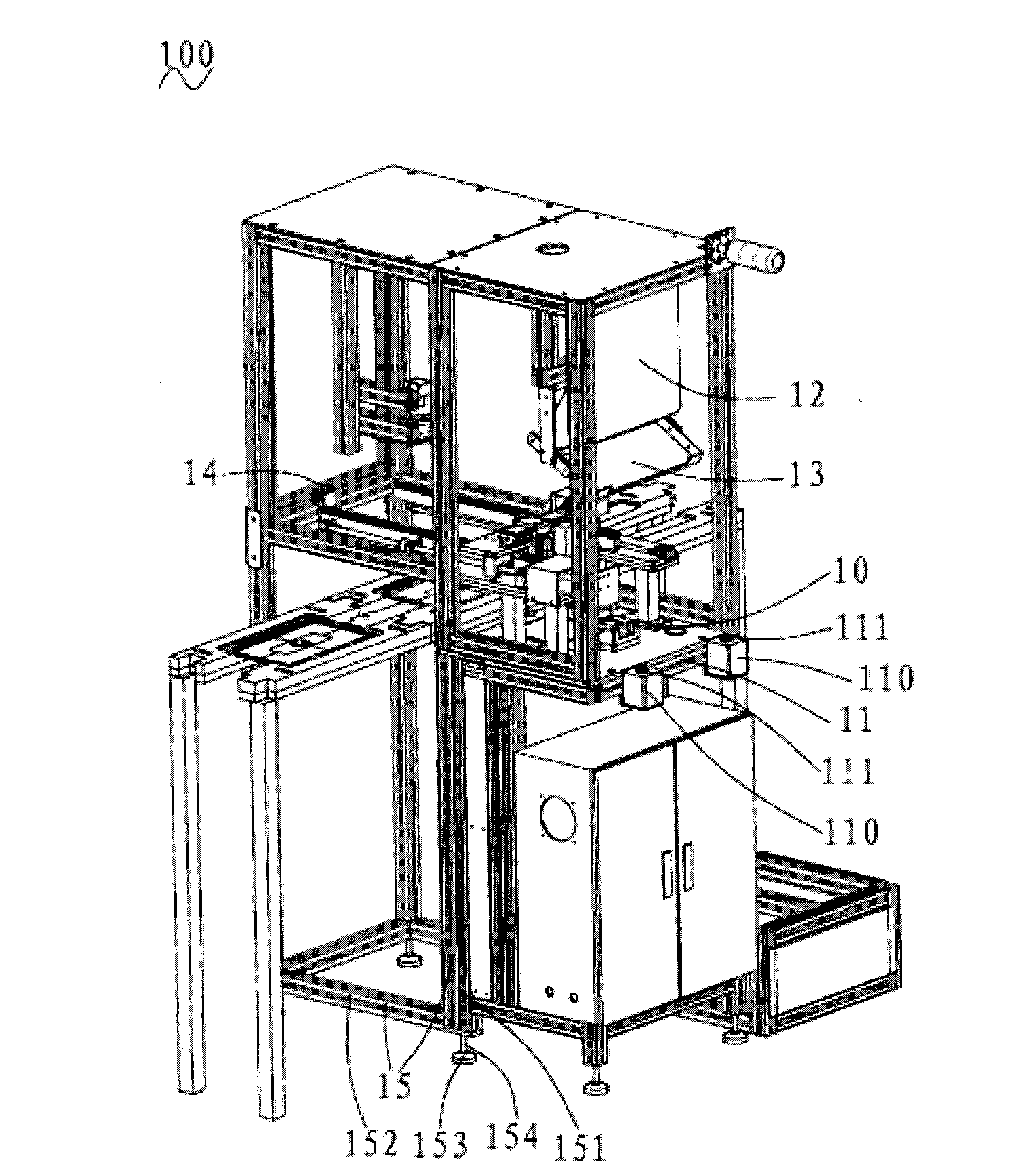

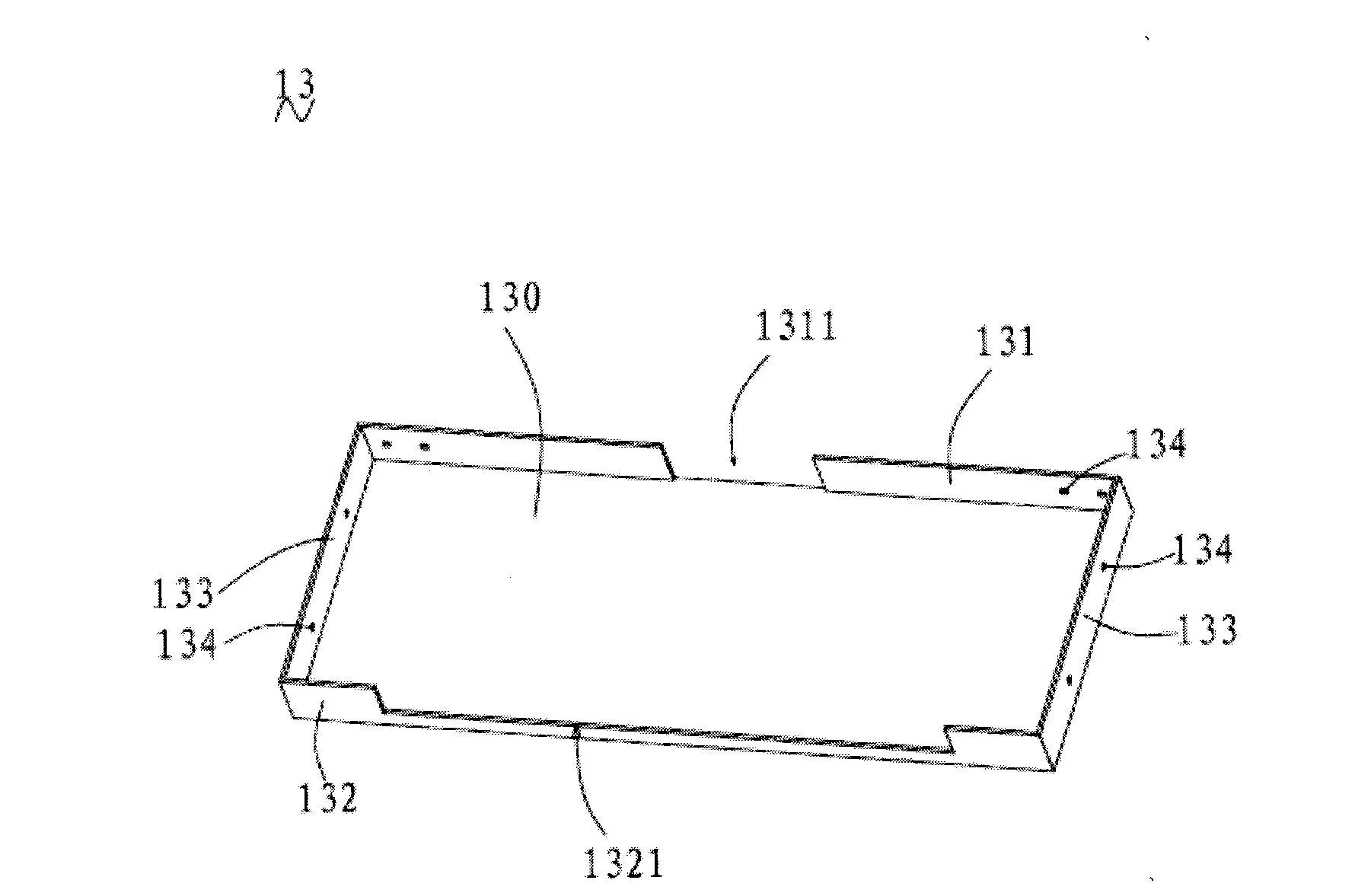

[0030] Such as figure 1 As shown, the trademark installation device 100 of the present invention includes a work table 10 for placing a trademark (unlabeled), a double switch button 111 for starting the trademark installation device, a display screen 12 for controlling and displaying the running status of the trademark installation device and placing There is a keyboard drawer 13 for the keyboard, a door lock 14, and a bracket 15 for the branded mounting equipment.

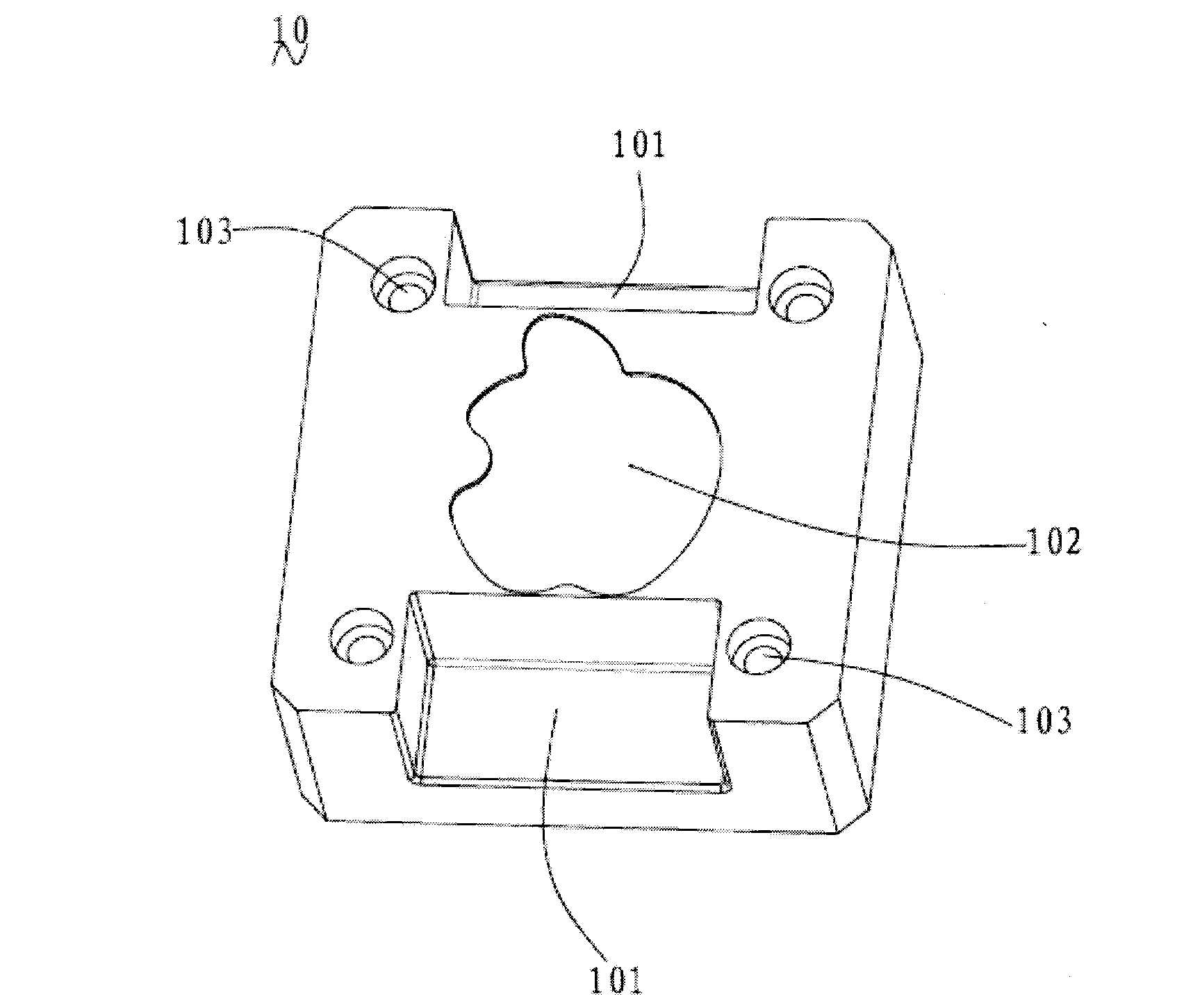

[0031] Such as figure 2 As shown, the two sides of the workpiece table 10 are respectively provided with a recessed opening groove 101, and between the opening grooves 101 on both sides are also provided with a storage groove 102 with the same size as the trademark to accommodate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com