Mounting structure for the dissipating wind surface in box electric fans

A technology of installation structure and wind surface, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

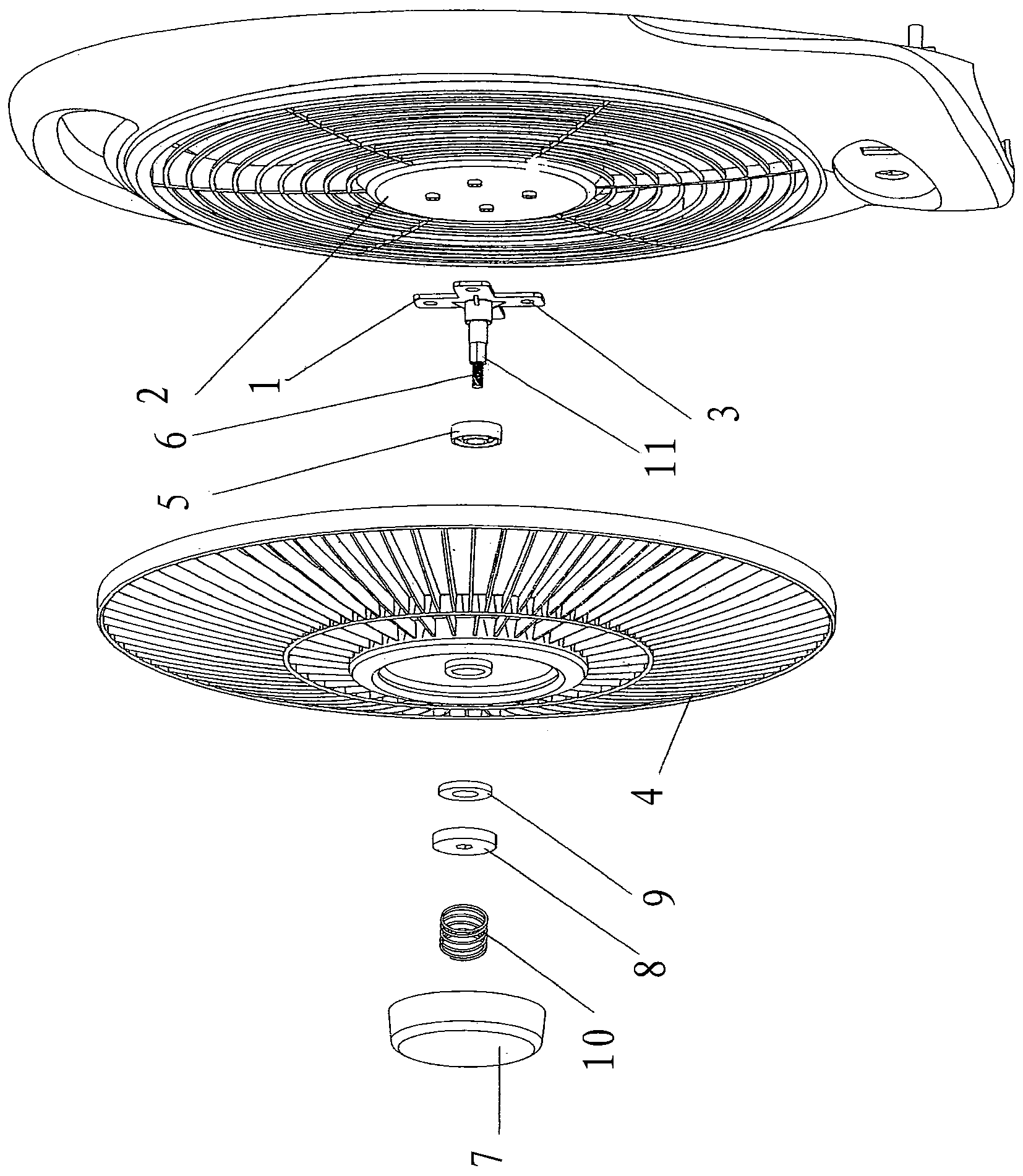

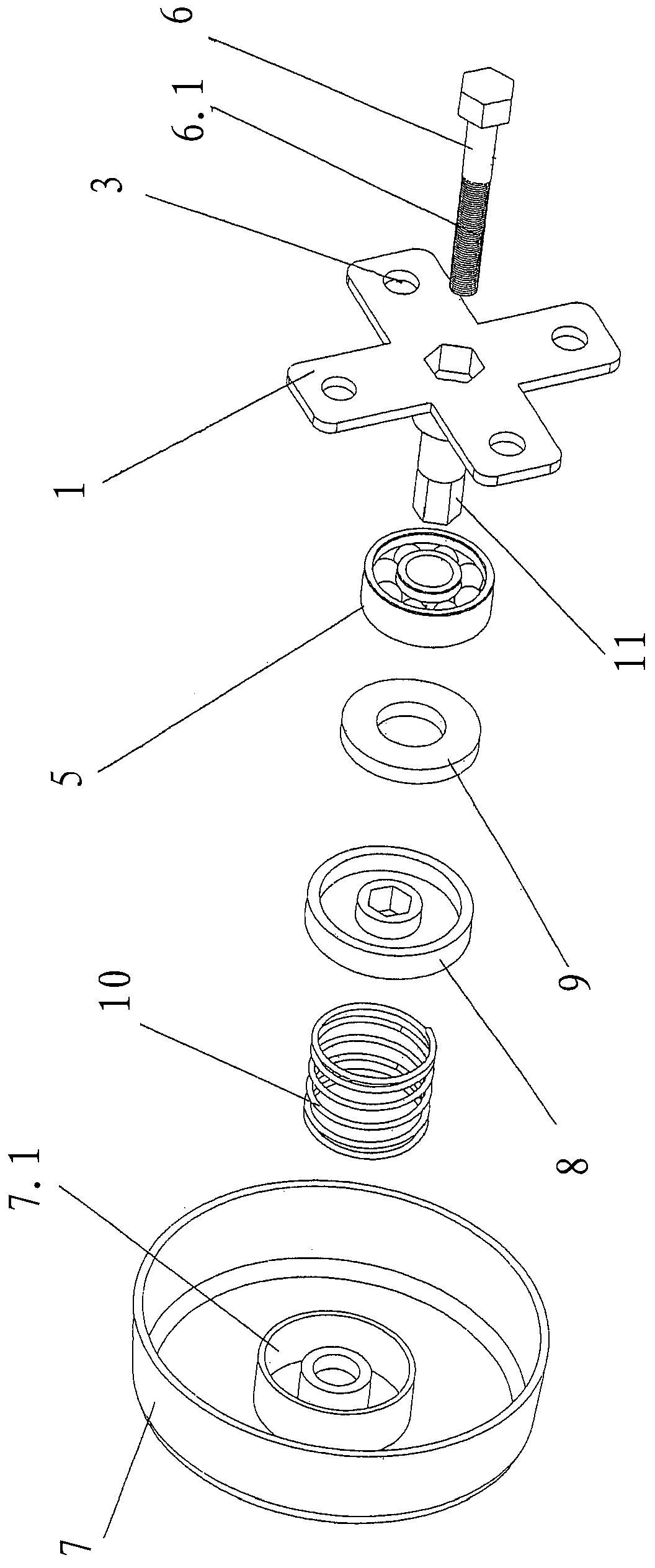

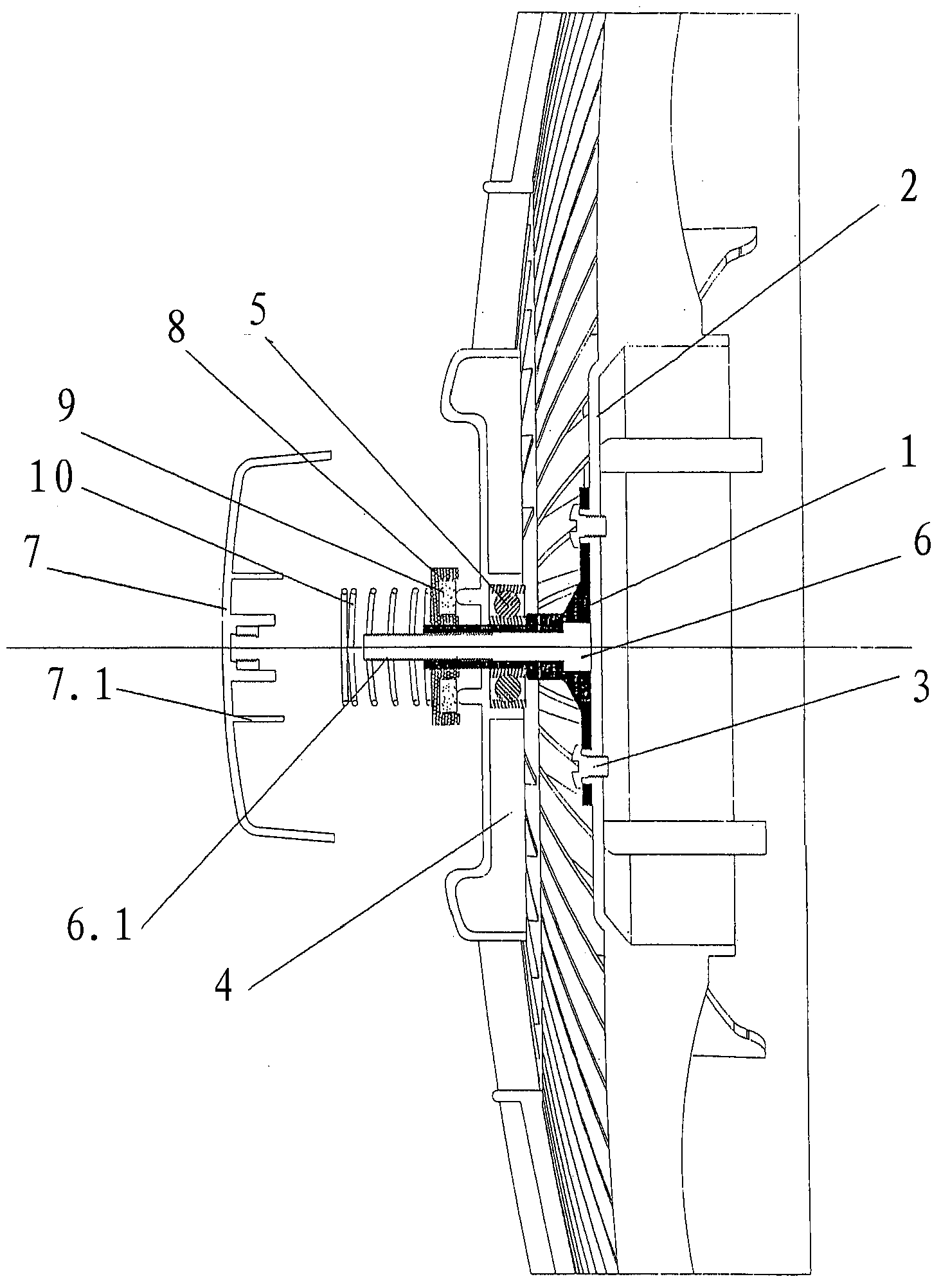

[0009] according to figure 1 , figure 2 with image 3 , according to the present invention, the mounting structure for the air diffuser surface includes: a cross-shaped plate 1, which is fixed to the front surface 2 of the box fan body by screws 3; the air diffuser surface 4 is equipped with an adapted bearing 5; an end A bolt 6 with a threaded portion 6.1 passes through said cross-shaped plate 1; the bolt 6 is fitted with a speed adjustment cap 7; This circular washer engages the corresponding hexagonal part 11 in the cross-shaped plate 1, an oil-impregnated felt ring 9 is mounted between the diffuser surface 4 and the circular washer 8, a spring 10 is inserted in the cylinder 7.1, This cylinder 7.1 is installed inside the speed adjustment cap 7.

[0010] according to image 3 , when the speed adjustment cap 7 is turned clockwise, the spring 10 will push the circular washer 8 against the air diffuser surface 4, which increases the friction between the air diffuser surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com