Zipper manufacturing device

A technology for manufacturing devices and zippers, which is applied in the field of zipper manufacturing devices, which can solve problems such as the influence of driving speed, the inability to process chains, and the difficulty in increasing output, and achieve the effect of high processing position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

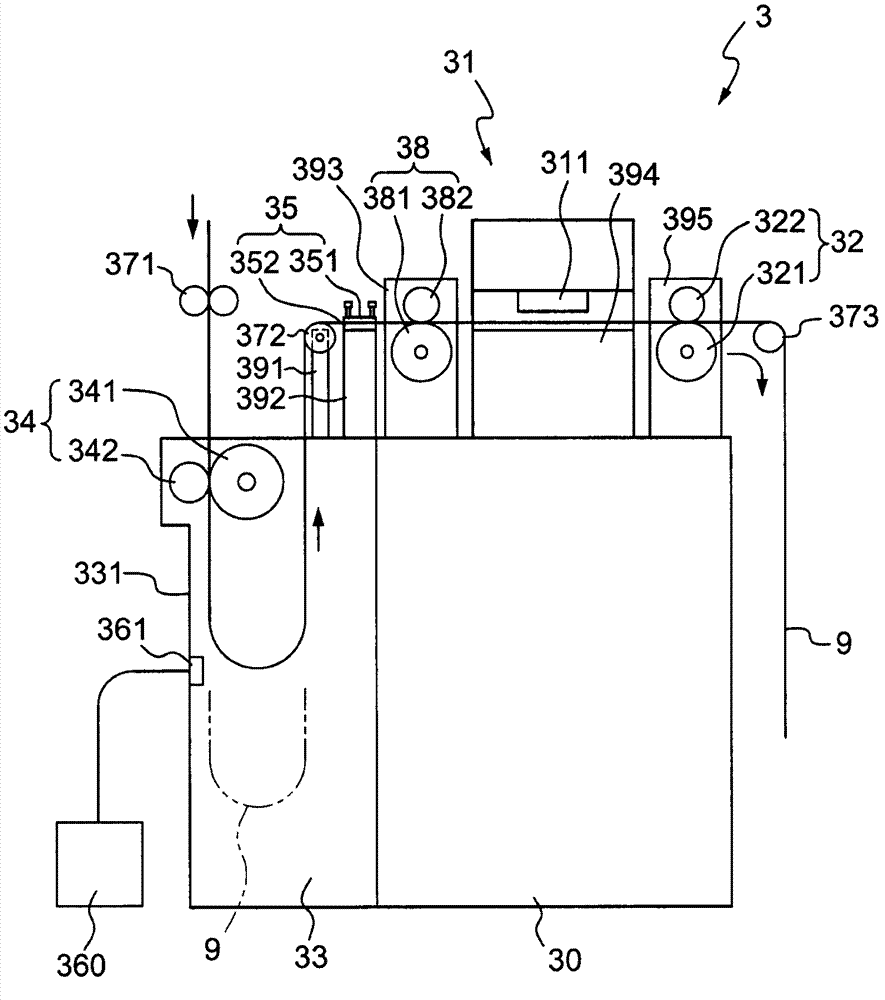

[0020] Please refer to image 3 , the zipper manufacturing device 3 of the present invention is used to process the semi-finished chain 9 for manufacturing a zipper. The slide fastener manufacturing apparatus 3 includes a passage, a processing unit 31 , a transport unit 32 , a storage unit 33 , a transport unit 34 , a tension applying unit 35 , and a length measuring unit 38 . Among them, in image 3 In the particular embodiment shown, the frame 331 of the storage part 33 is fixed to the side of the machine table 30 of the zipper manufacturing device 3 .

[0021] In the zipper manufacturing device 3, the chain 9 moves along the path (please refer to image 3 the path of chain 9). The processing part 31 is disposed on the passage for processing the chain 9 . The conveying part 32 is arranged on the passage, and is used for moving the chain 9 to pass through the processing part 31 along the passage. The storage part 33 is provided on the passage and upstream of the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com