Torsional spring mechanism generating symmetrical torque

A torsion spring and symmetrical technology, applied in the field of torsion spring mechanism, can solve the problems of inconvenient docking, large volume and weight of loading table, expensive loading table, etc., and achieve the effect of low cost and simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below through embodiment form, content of the present invention is described in further detail, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical idea of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

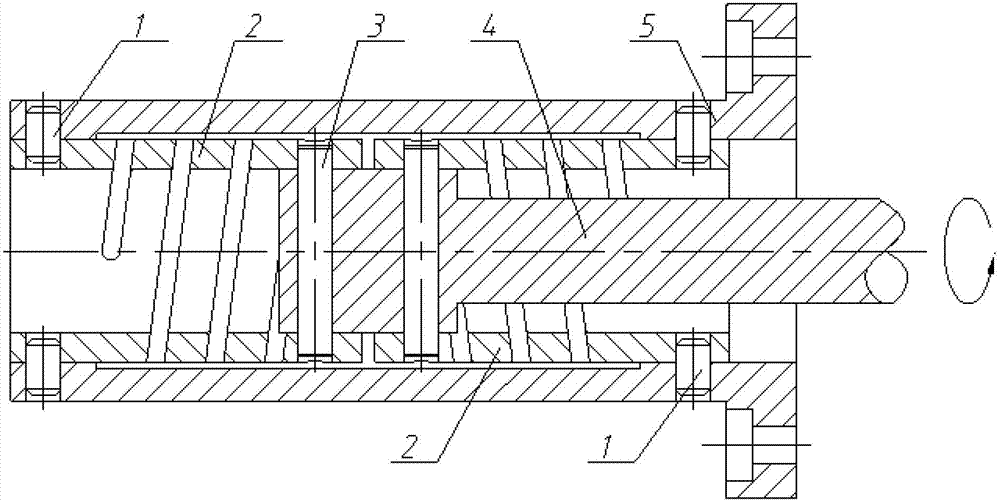

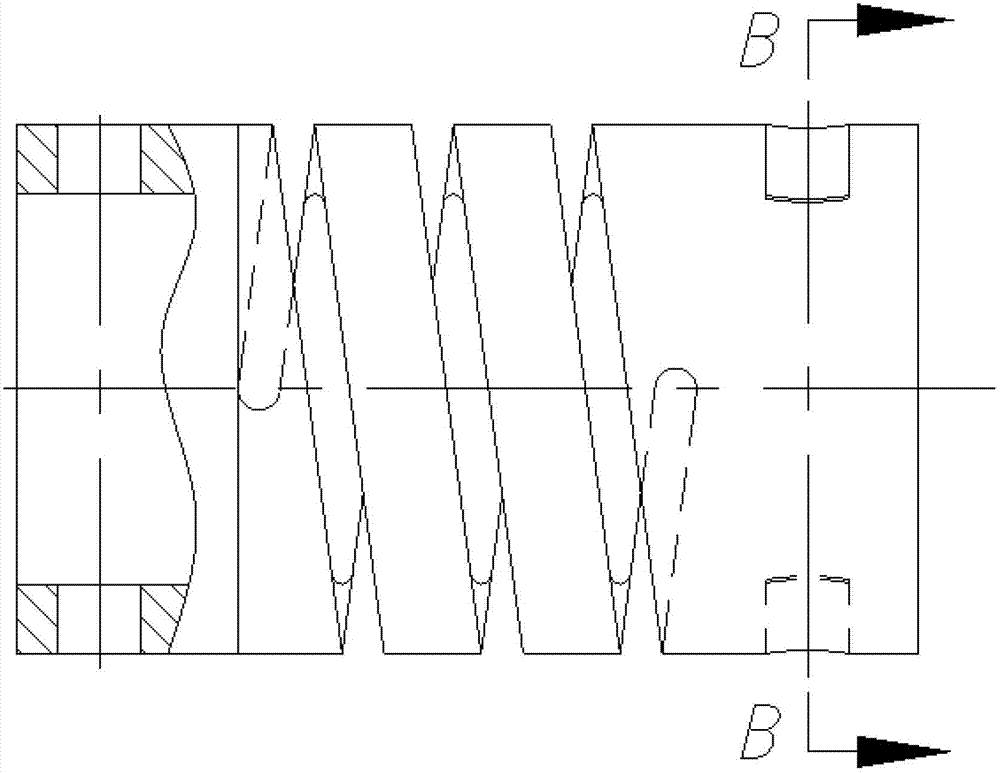

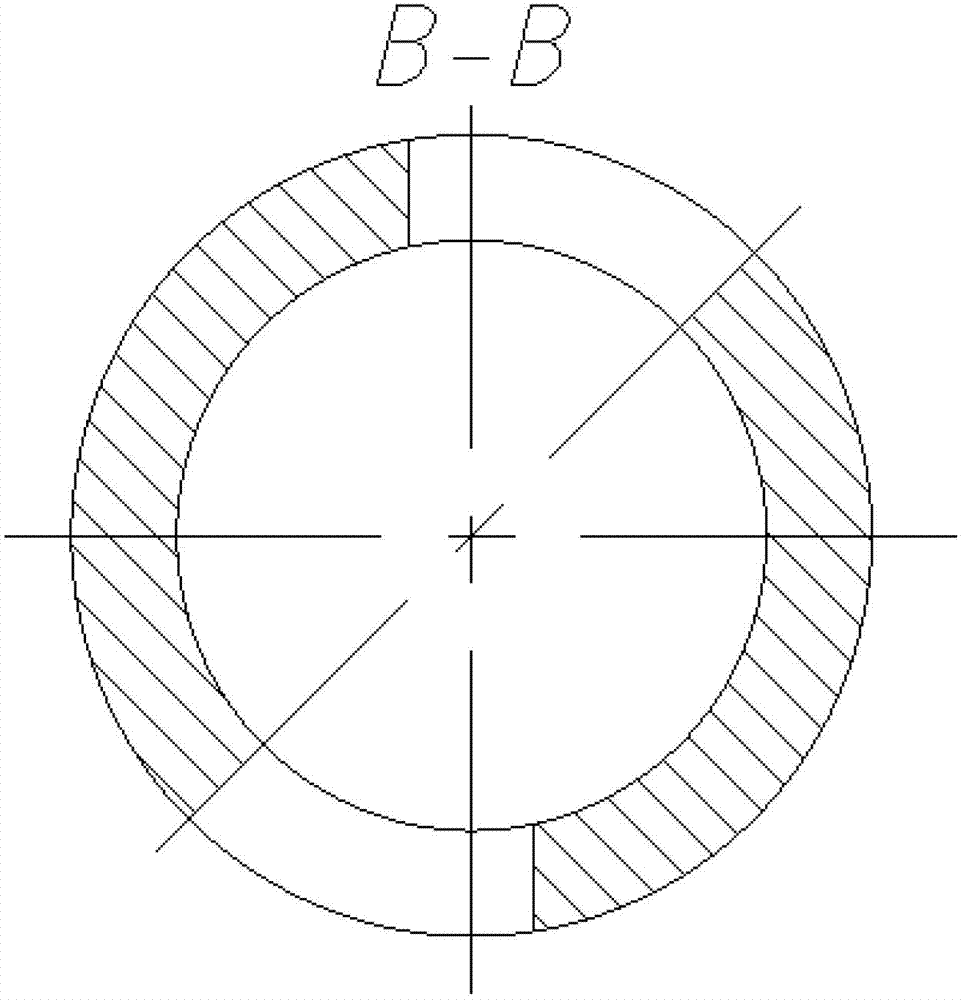

[0016] Such as figure 1 , figure 2 and image 3 As shown, the present invention mainly comprises fixed pin 1, torsion spring 2, connecting pin 3, power shaft 4 and sleeve 5, and the side wall of sleeve 5 has positioning hole, and the bottom is provided with the installation hole that docks with other devices, torsion spring 2 is a cylindrical structure, one end has a positioning hole, and the other end has a strip groove along its outer wall. When working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com