Single-H operated power takeoff electrical control system capable of carrying out traveling power take-off and use method of electrical control system

An electronic control system and power take-off technology, applied in the direction of control devices, vehicle components, circuits or fluid pipelines, etc., can solve the problems of unsafe driving power take-off and low practicability, and avoid sudden lifting. , the effect of avoiding sudden lifting and safe parking to take power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

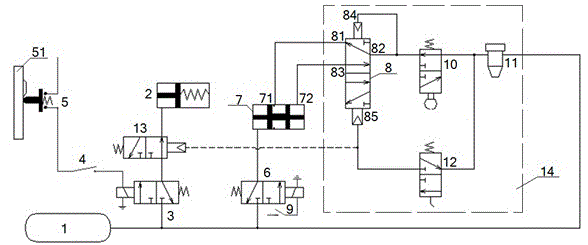

[0044] A single H-operated power take-off electric control system capable of taking power from vehicles, including air reservoir 1, power take-off 2, power take-off solenoid valve 3, power take-off switch 4, low gear control switch 5, parking solenoid valve 6, The middle cylinder 7, the parking switch 9, the high-end shielding valve 13 and the rear auxiliary box H control system 14. The rear auxiliary box H control system 14 includes a single H valve 8, a stop valve 10, a pressure limiting valve 11 and a handle control valve 12;

[0045] The air reservoir 1 communicates with the air inlet of the power take-off 2 after passing through the power take-off solenoid valve 3 and the high-end shielding valve 13 (the air inlet of the power take-off 2 communicates with the rod cavity of the control cylinder of the power take-off 2 ), the output shaft of the power take-off 2 is connected to the gear pump; the air reservoir 1 communicates with the air inlet of the middle cylinder 7 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com