Biosensor and manufacturing method thereof

A technology of biosensors and manufacturing methods, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems such as delayed manufacturing efficiency and rising waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

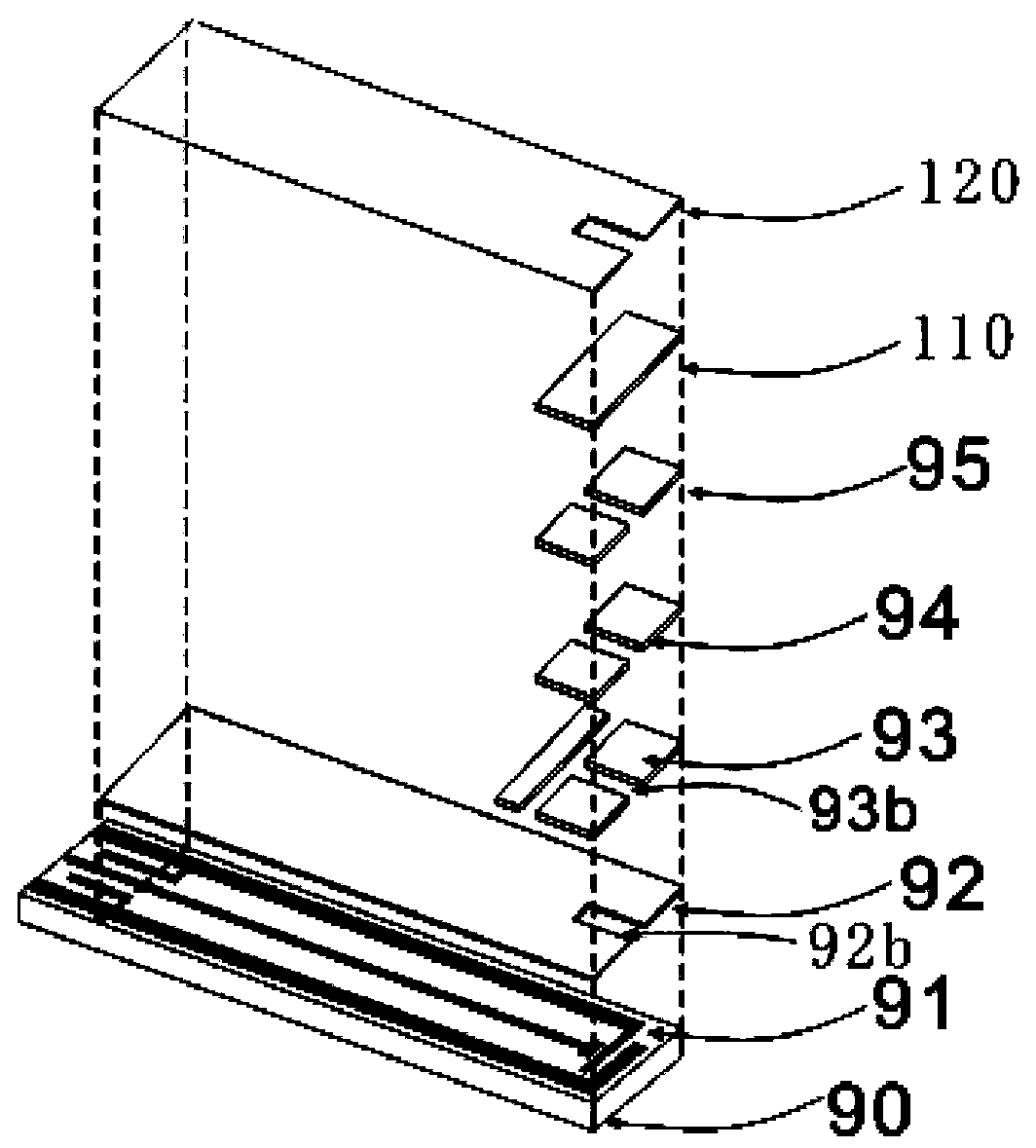

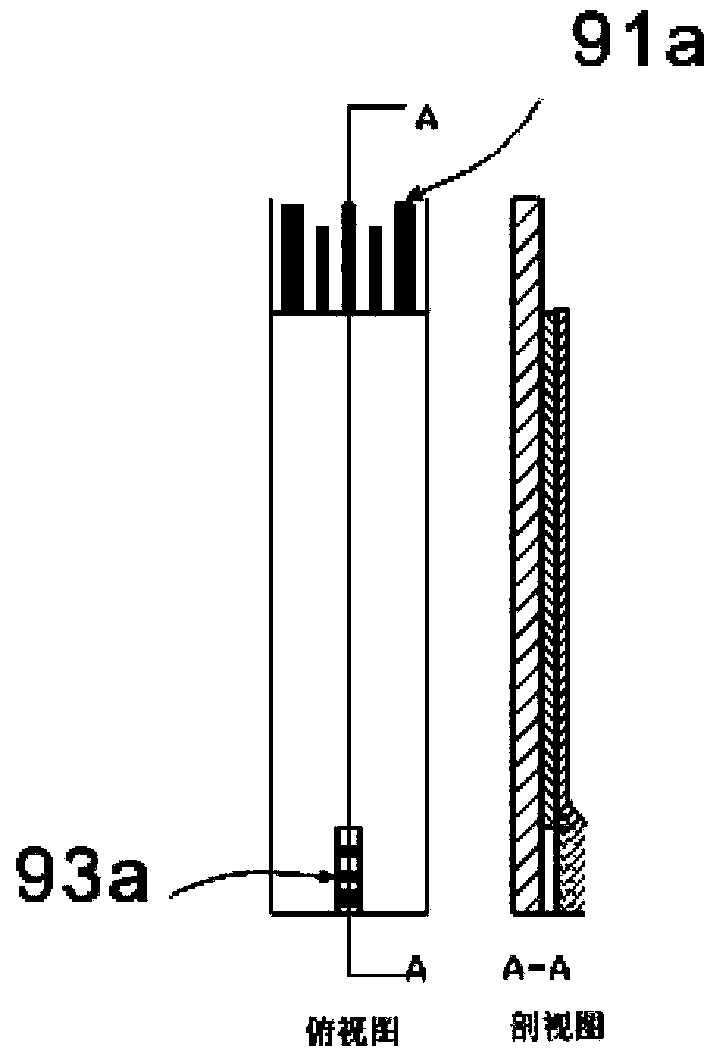

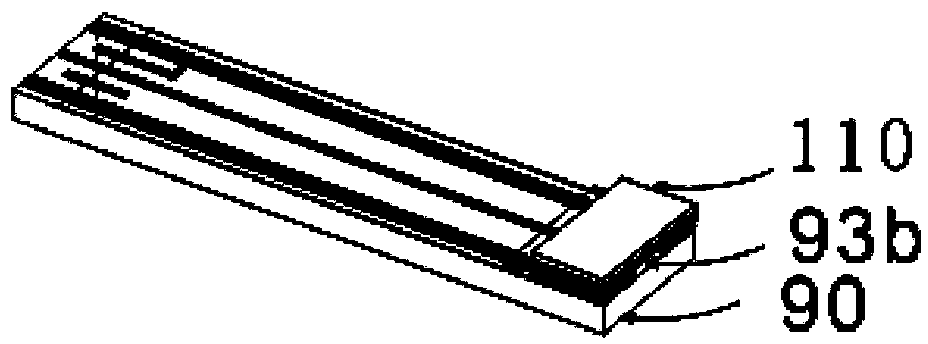

[0017] The invention uses the electrochemical principle to apply the biosensor to the detection of physiological parameters, and can be used to qualitatively or quantitatively measure specific substances in biological samples. The sensor is composed of various materials. It is built on a substrate or carrier, and electrode wires are printed on the substrate. The number of electrodes can be two levels, working electrode and counter electrode, or multi-level electrodes. A layer of insulating material is printed on the substrate where the electrodes are printed, and this layer of insulating material defines the reaction area of the sensor reaction area; on the substrate with the printed reaction area, the pad layer and the appropriate groove are printed again around the periphery of the reaction area, There is an opening near the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com