Frame specification conversion structure

A technology for converting structures and specifications, applied in the direction of bicycle racks, bicycle accessories, transportation and packaging, etc., to achieve the effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

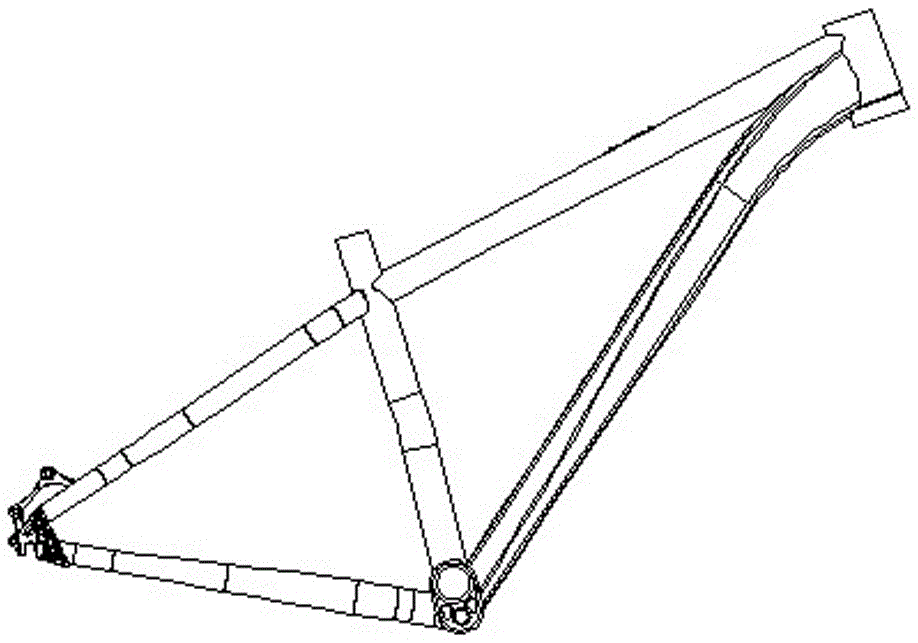

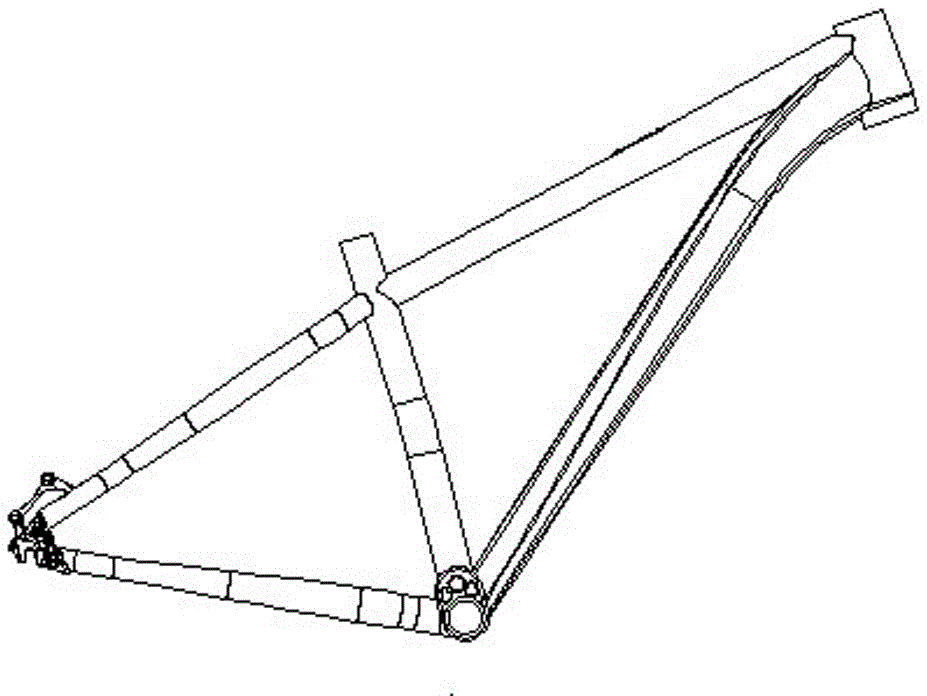

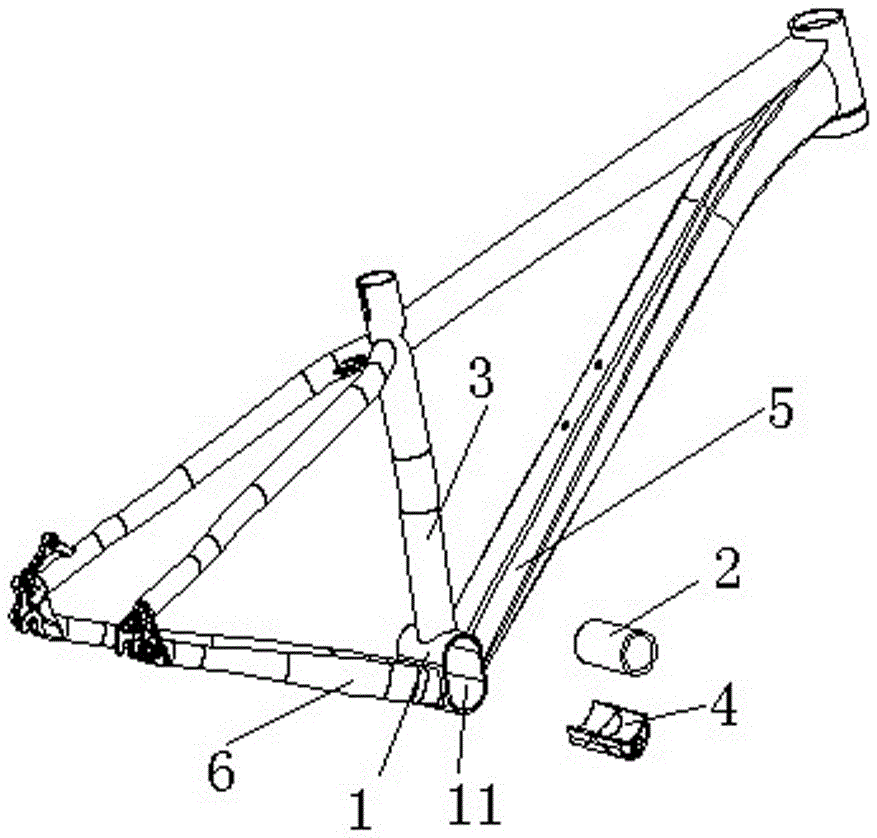

[0031] One of the embodiments, combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , described in detail below:

[0032] A vehicle frame specification conversion structure, comprising a bottom bracket connecting pipe 1 for connecting the lower fork pipe 6, the middle pipe 3 and the lower pipe 5, the bottom bracket connecting pipe has a grooved nozzle 11 along the axial direction of the middle pipe 3 (such as image 3 As shown), it also includes a shaft hole tube 2 passing through the grooved nozzle and used to fix the toothed disc. A detachable adjustment block 4 is also provided on the side of the grooved nozzle. The section of the adjustment block is a crescent surface. And when the adjusting block is inserted into one side of the grooved nozzle, the crescent surface and the grooved nozzle form a circular mouth that is convenient for fixing the shaft hole pipe 2, so as long as the adjustment block 4 and the shaft hole pipe 2 are changed The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com