Measuring method for spreading rate in paper-making reconstituted tobacco production process

A technology for reconstituted tobacco leaves and production process, which is applied in the field of coating rate detection in the production process of reconstituted tobacco leaves by a papermaking method, and can solve problems such as hidden dangers in production safety, the inability to accurately express the true value of the coating rate, and the interruption of continuous production of paper webs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Below in conjunction with the measurement method of traditional detection spreading rate and the measuring method of the measuring method of spreading rate of papermaking method reconstituted tobacco leaf production process described in the present invention, the two measured results are compared, and the specific comparison results are as follows:

[0017] Example 1: Reconstituted Tobacco Leaf Brand A Product, Spreading Rate Index (35±1.5)%

[0018] Existing detection methods:

[0019] Use a quantitative knife to cut 20 pieces of 100cm evenly along the direction of the substrate before coating 2 Put the sample in the sample box, dry it in a blast drying oven at (105±2)°C for 2 hours, take it out and cool it in the desiccator, and weigh it (m 1 20 film bases) of mass

[0020] Use a quantitative knife to evenly cut 20 pieces of 100cm along the horizontal direction of the coated sheet 2 Dry the sample in a blast drying oven at (105±2)°C for 2 hours, take it out and coo...

Embodiment 2

[0031] Example 2 Reconstituted tobacco leaf B brand product, coating rate index (33.5±1.5)%

[0032] Existing detection methods:

[0033] Use a quantitative knife to cut 20 pieces of 100cm evenly along the direction of the substrate before coating 2 Put the sample in the sample box, dry it in a blast drying oven at (105±2)°C for 2 hours, take it out and cool it in the desiccator, and weigh it (m 1 20 film bases) of mass

[0034] Use a quantitative knife to evenly cut 20 pieces of 100cm along the horizontal direction of the coated sheet 2 Dry the sample in a blast drying oven at (105±2)°C for 2 hours, take it out and cool it in a desiccator, and weigh m 2 (20 film bases) quality.

[0035] calculation method

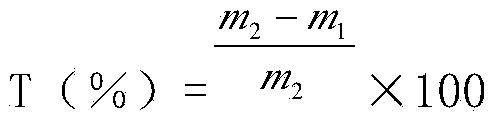

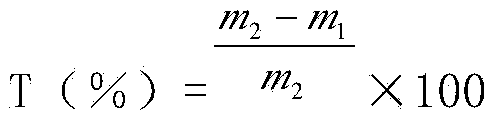

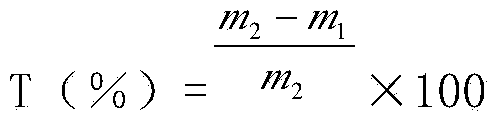

[0036] Sheet Spread Rate: T ( % ) = m 2 - m 1 m ...

Embodiment 3

[0046] Example 3: Reconstituted Tobacco Leaf Brand A Product, Spreading Rate Index (34±1.5)%

[0047] Existing detection methods:

[0048] Use a quantitative knife to cut 20 pieces of 100cm evenly along the direction of the substrate before coating 2 Put the sample in the sample box, dry it in a blast drying oven at (105±2)°C for 2 hours, take it out and cool it in the desiccator, and weigh it (m 1 20 film bases) of mass

[0049] Use a quantitative knife to evenly cut 20 pieces of 100cm along the horizontal direction of the coated sheet 2 Dry the sample in a blast drying oven at (105±2)°C for 2 hours, take it out and cool it in a desiccator, and weigh m 2 (20 film bases) quality.

[0050] calculation method

[0051] Sheet Spread Rate: T ( % ) = m 2 - m 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com