Municipal sludge solidification ecological treatment process

A municipal sludge and ecological technology, applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of late start of sludge disposal, land occupation, secondary pollution, etc. , to avoid infectious pollution and protect water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

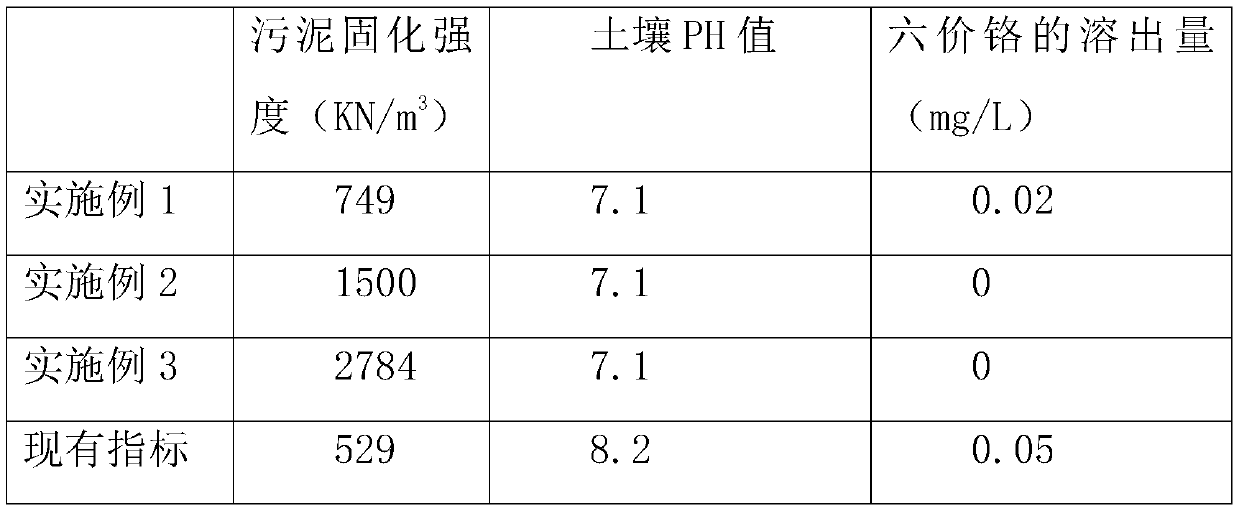

Embodiment 1

[0033] A municipal sludge solidification ecological disposal process, the process steps comprising:

[0034] (1) Preparation before construction

[0035] Solidify the 3 natural pits and ponds, and the larger pile has a volume of 33058.30m 3 Sludge, the second piled up has 9544.20m 3 , the smallest pile is 2053.90m 3 , After entering the site, firstly carry out foundation clearing and leveling. According to the site conditions, a combination of mechanical and manual cleaning is used for cleaning. The depth of foundation cleaning is 25cm. The turf, tree roots and other sundries on the ground must be removed, and the sundries are loaded and unloaded by the excavator. Cars are transported to the spoil yard, and the site is leveled after the foundation clearing is completed, and temporary roads are built according to the construction needs;

[0036] (2) Set up a stirring tank

[0037] Choose a suitable location on the construction site to set up 2 mixing tanks. The mixing tank ...

Embodiment 2

[0053] A municipal sludge solidification ecological disposal process, the process steps comprising:

[0054] (1) Preparation before construction

[0055] Solidify the 3 natural pits and ponds, and the larger pile has a volume of 33058.30m 3 Sludge, the second piled up has 9544.20m 3 , the smallest pile is 2053.90m 3 , After entering the site, firstly carry out foundation clearing and leveling. According to the site conditions, a combination of mechanical and manual cleaning is used for cleaning. The depth of foundation cleaning is 25cm. The turf, tree roots and other sundries on the ground must be removed, and the sundries are loaded and unloaded by the excavator. Cars are transported to the spoil yard, and the site is leveled after the foundation clearing is completed, and temporary roads are built according to the construction needs;

[0056] (2) Set up a stirring tank

[0057] Choose a suitable location on the construction site to set up 2 mixing tanks. The mixing tank ...

Embodiment 3

[0073] A municipal sludge solidification ecological disposal process, the process steps comprising:

[0074] (1) Preparation before construction

[0075] Solidify the 3 natural pits and ponds, and the larger pile has a volume of 33058.30m 3 Sludge, the second piled up has 9544.20m 3 , the smallest pile is 2053.90m 3 , After entering the site, firstly carry out foundation clearing and leveling. According to the site conditions, a combination of mechanical and manual cleaning is used for cleaning. The depth of foundation cleaning is 25cm. The turf, tree roots and other sundries on the ground must be removed, and the sundries are loaded and unloaded by the excavator. Cars are transported to the spoil yard, and the site is leveled after the foundation clearing is completed, and temporary roads are built according to the construction needs;

[0076] (2) Set up a stirring tank

[0077] Choose a suitable location on the construction site to set up 2 mixing tanks. The mixing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com