A palletizing robot suction cup gripper device

A palletizing robot and gripper device technology, applied in the direction of manipulator, program-controlled manipulator, stacking of objects, etc., can solve the problems of random swing, unstable and reliable box materials, and inability to change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

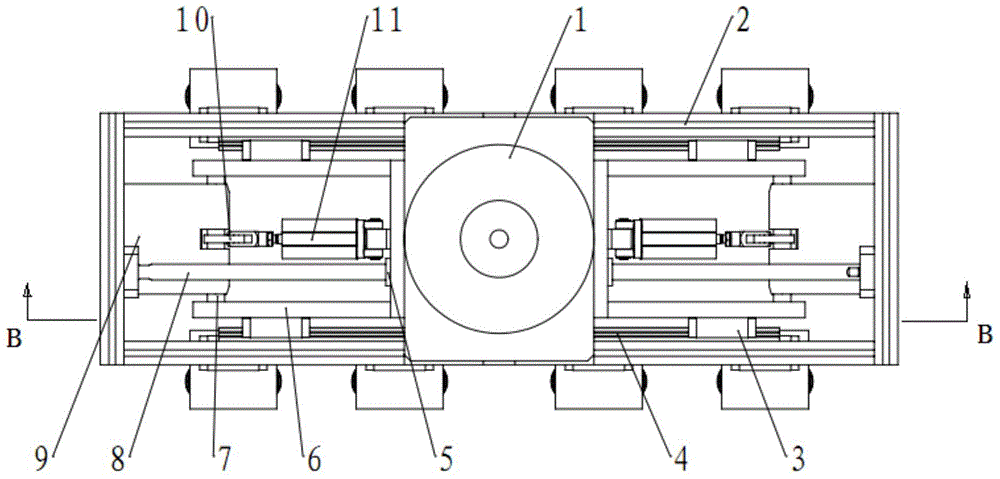

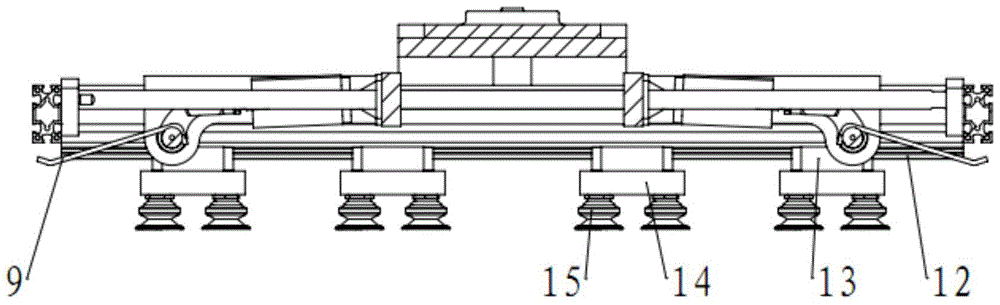

[0013] Referring to the accompanying drawings, a palletizing robot suction cup gripper device includes a connecting flange 1, a main frame, a splint mechanism, a width adjustment mechanism, and a suction unit; the main frame is composed of spliced aluminum profiles 2, and the connecting flange 1 is fixed on the main frame The top is fixedly connected with the mechanical wrist, and the splint mechanism includes a splint cylinder slide rail 4, a splint cylinder slide block 3, a splint cylinder 11, a splint support 6, a splint cylinder rotating shaft 7, and a splint cylinder swing arm 10, and the splint cylinder slide rail 4 is fixed on the On the main body frame, the splint cylinder slider 3 is fixed on the clamping cylinder slide rail 4, the clamping plate 9 is fixed on the splint cylinder rotating shaft 7, and the splint cylinder rotating shaft 7 is fixedly connected with the splint cylinder 11 through the splint cylinder swing arm 10, The splint cylinder 11 is fixed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com