Working machine and maintenance inspection information generating device

A technology for operating machinery and checking information, which is applied in computer control, earth movers/shovels, instruments, etc., can solve the problems of difficulty in use, deviation and complexity of the accuracy of part life estimation, and achieve the goal of improving the accuracy of inference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

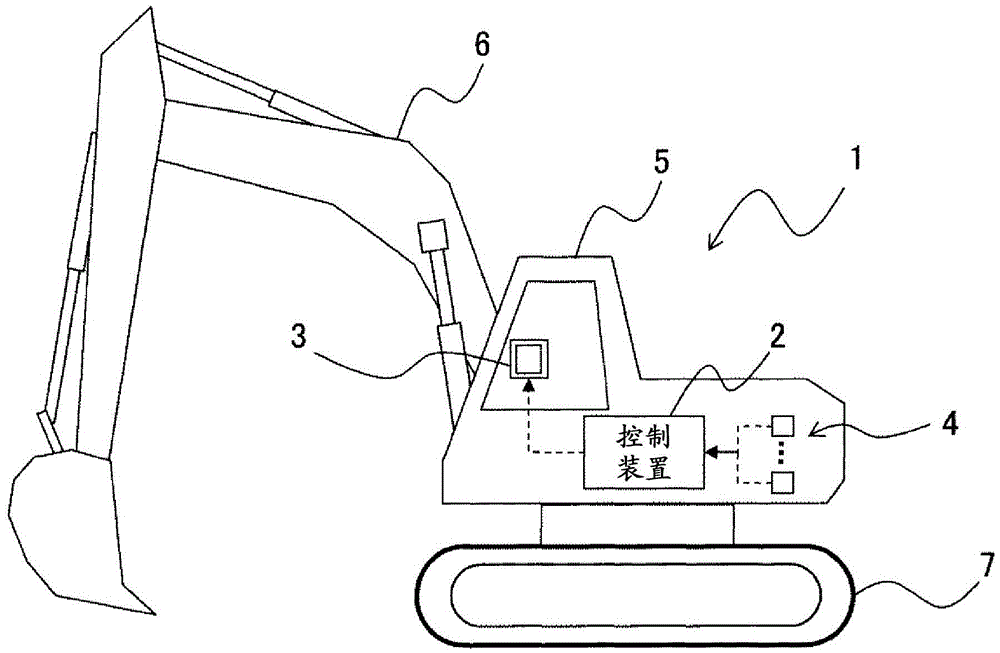

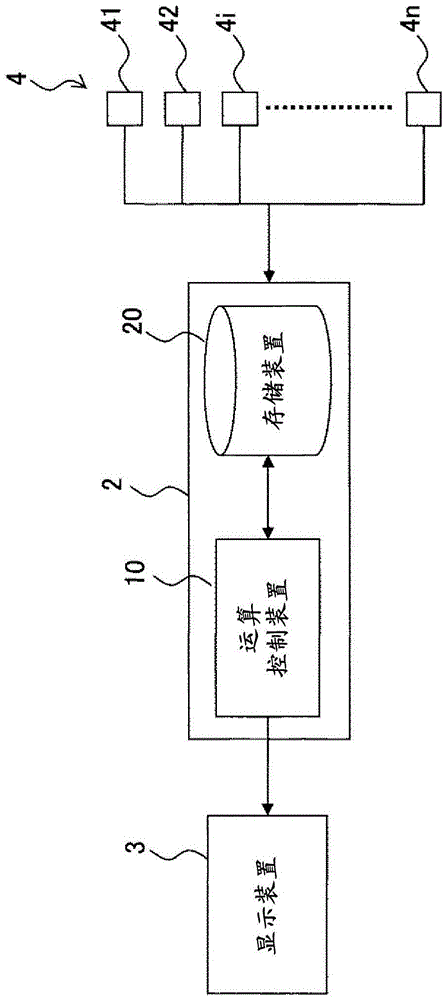

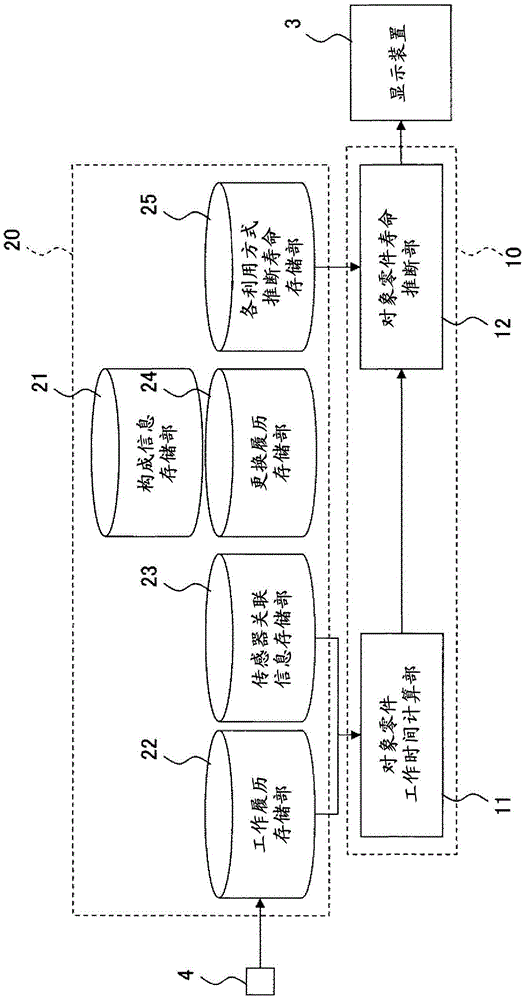

[0032] figure 1 It is a configuration diagram of the working machine according to the first embodiment of the present invention, figure 2 is a schematic diagram of the control device and its peripheral hardware configuration according to the first embodiment of the present invention, image 3 yes figure 2 A specific diagram of the hardware configuration shown. Here, if figure 1 As shown, an embodiment in which a construction machine hydraulic excavator is used as a working machine will be described.

[0033] figure 1 The hydraulic excavator (work machine) 1 shown is composed of a plurality of parts, and has: a lower traveling body 7; an upper rotating body 5 mounted rotatably on the upper part of the lower traveling body 7; A multi-joint type working device 6 on 5; a sensor group 4 composed of a plurality of sensors that detect the work history of each part cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com