synchronization ring

A technology of synchronizing ring and synchronizer, applied in the field of synchronizing ring, can solve problems such as flange damage, and achieve the effect of easy ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

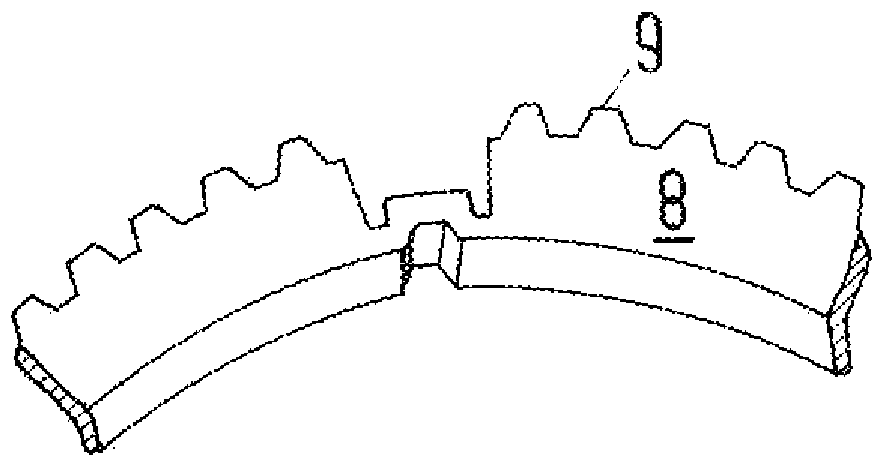

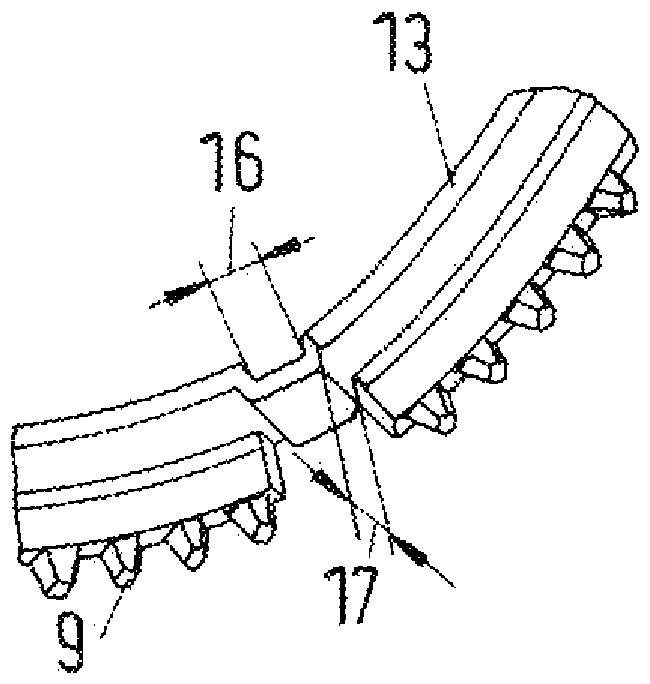

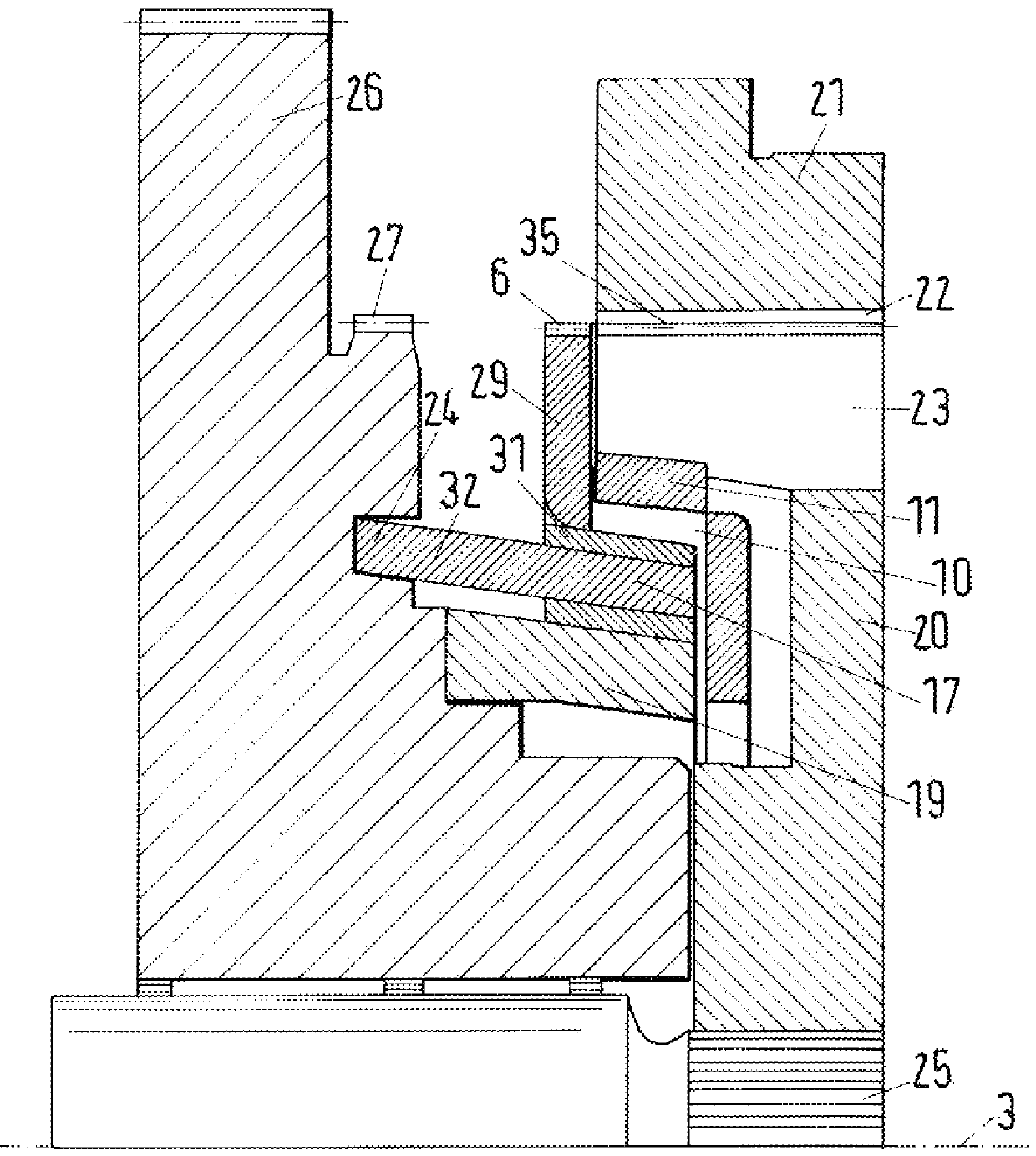

[0042] Basis for synchronizers for shiftable gearshift transmissions Figure 1a The synchro ring 1 has a ring body 2 . The ring body 2 is arranged around the synchronizer ring axis 3 . The ring body has an inner friction surface 4 and an outer mounting surface 5 . The inner friction surface 4 and the outer mounting surface 5 delimit the ring body 2 in the radial circumferential direction. The ring body 2 has a toothing 6 extending from a gear base bar 7 which surrounds the ring body radially and is present at the end face of the ring body. The gear surface 8 extends substantially perpendicular to the synchronizer ring axis. The gear base strip 7 is axially delimited by a gear surface 8 . The gear base bar 7 supports the teeth of the toothed arrangement 6 . The recess 10 is arranged at the inner friction surface 4 of the ring body 2 such that the radius 14 of the inner friction surface at the end face 13 in the region of the recess 10 is greater than the radius 12 of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com