Web-fed presses

A technology of printing presses and reels, applied in printing presses, rotary presses, printing, etc., can solve the problems of large building heights and impossibility of integration, and achieve the effect of reducing building heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

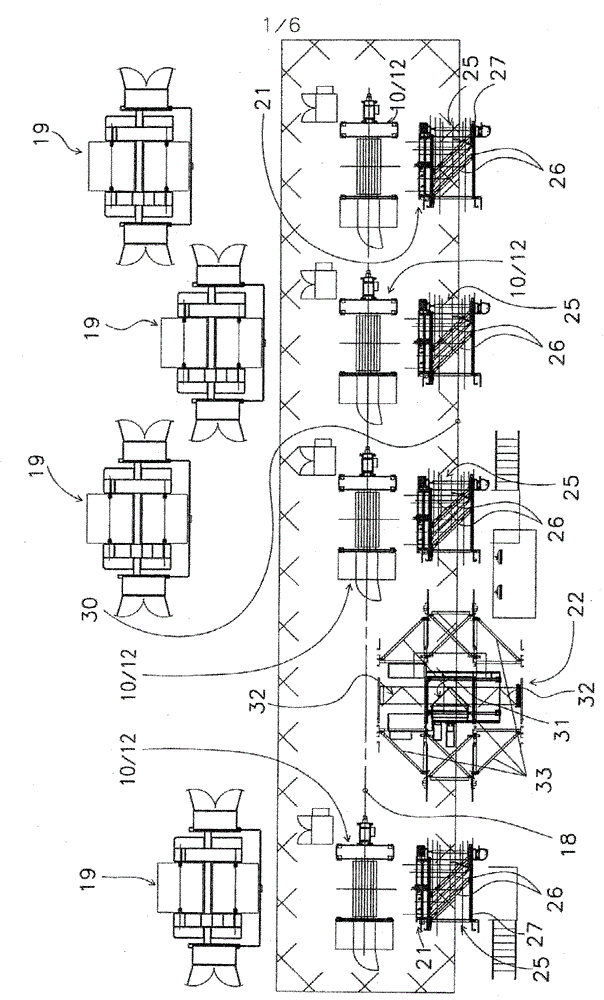

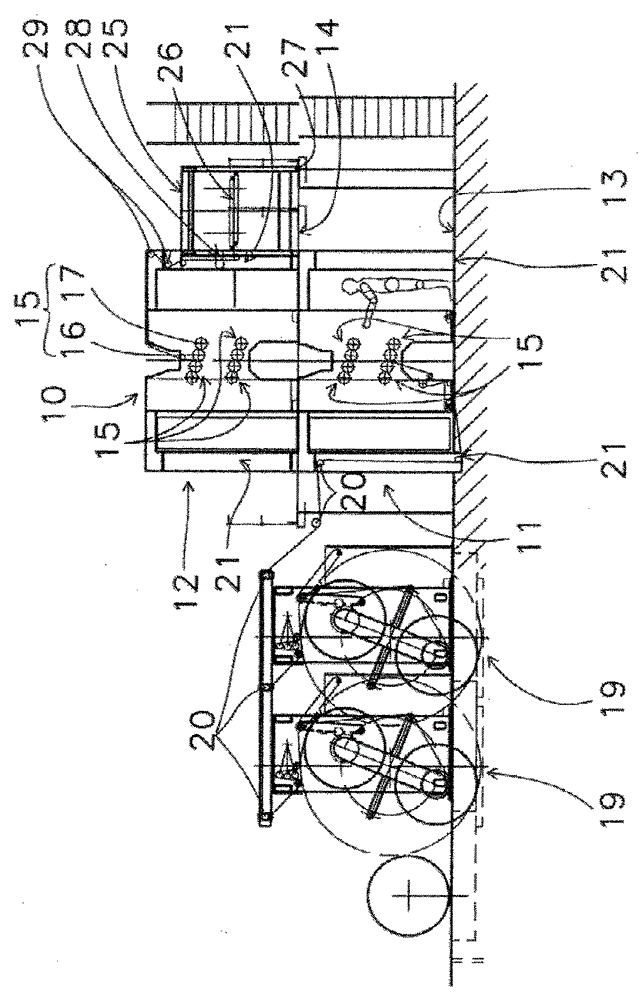

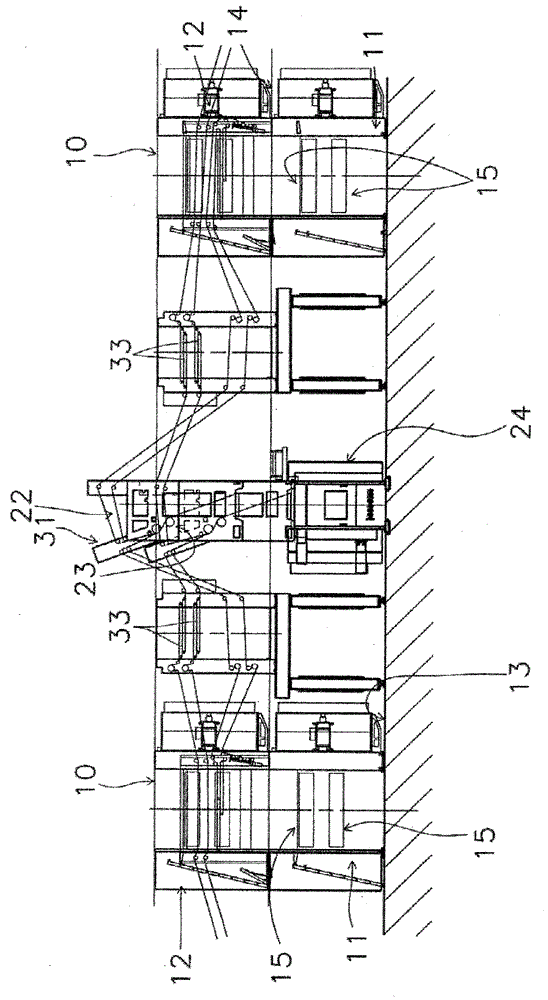

[0046] Figure 1-3 Shows different views of a web-feed printing machine designed as a newspaper printer according to the present invention, where in the exemplary embodiment shown, the web-feed printing machine as a whole includes two printing units 11, 12 The two printing units 11, 12 are each vertically positioned to overlap each other.

[0047] The first printing unit 11 on the lower side of each printing tower 10 figure 2 with 3 It is most clearly positioned on the floor 13 of the printing hall and can be operated from the floor 13 of the printing hall by an operator. The second printing unit 12 on the upper side of each printing tower 10 is vertically positioned above the first printing unit 11 of the corresponding printing tower 10 and can be operated based on a platform 14 formed above the floor 13 of the printing hall.

[0048] In the exemplary embodiment shown, the printing units 11, 12 of each printing tower 10 are implemented as so-called eight-cylinder printing units,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com