Series oil cylinder reversing control method and device and concrete pumping system

A technology of a reversing control device and a control method, which is applied in the field of control, can solve the problem that an oil cylinder cannot be reversed, and achieves the effects of enhancing reliability and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

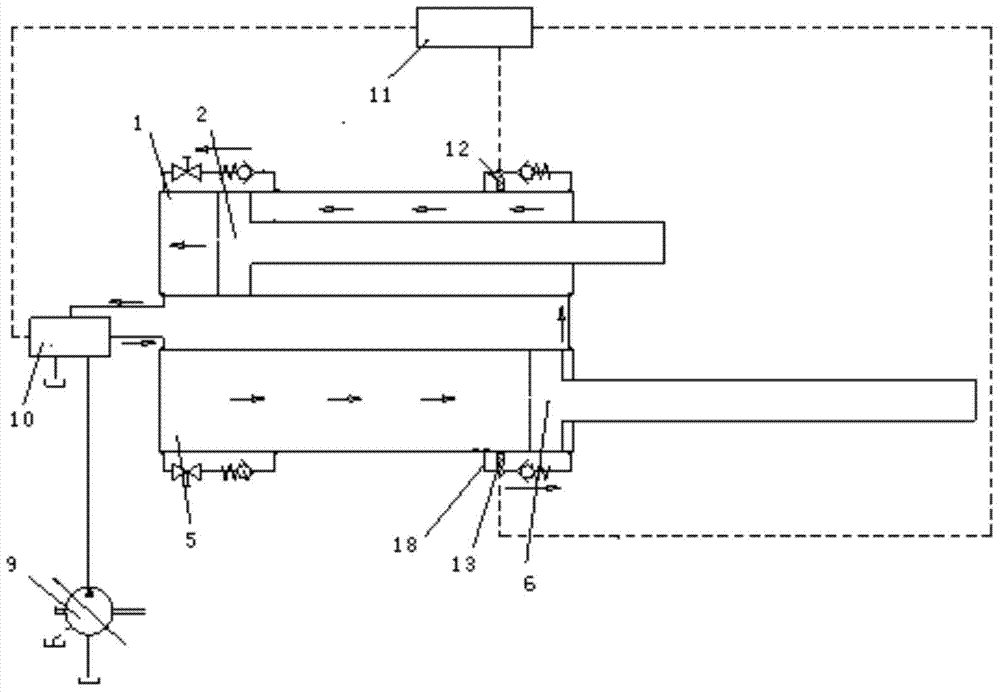

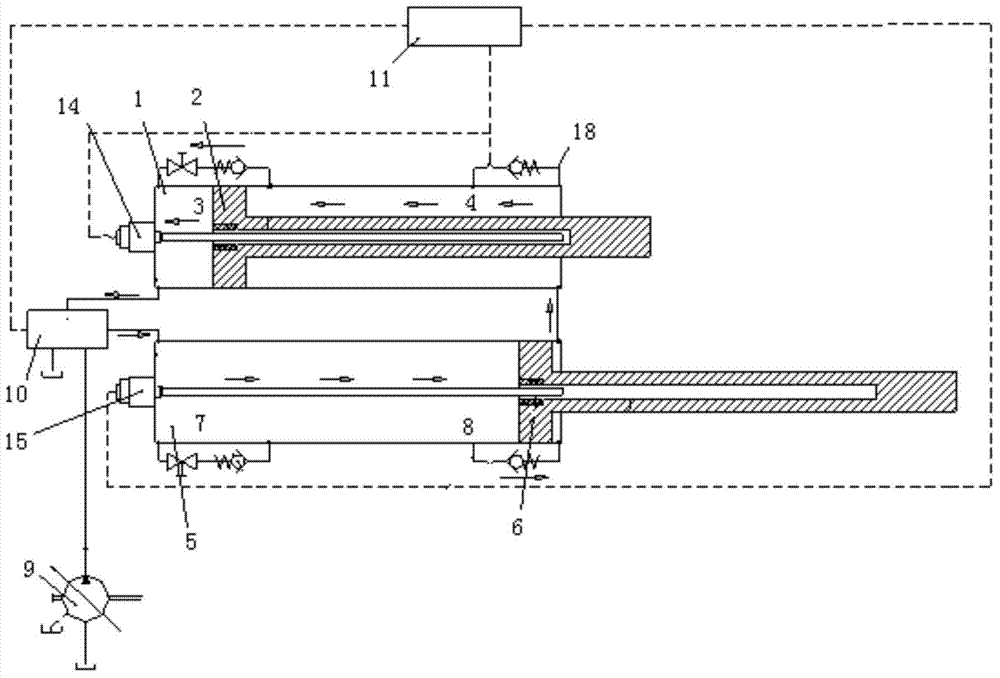

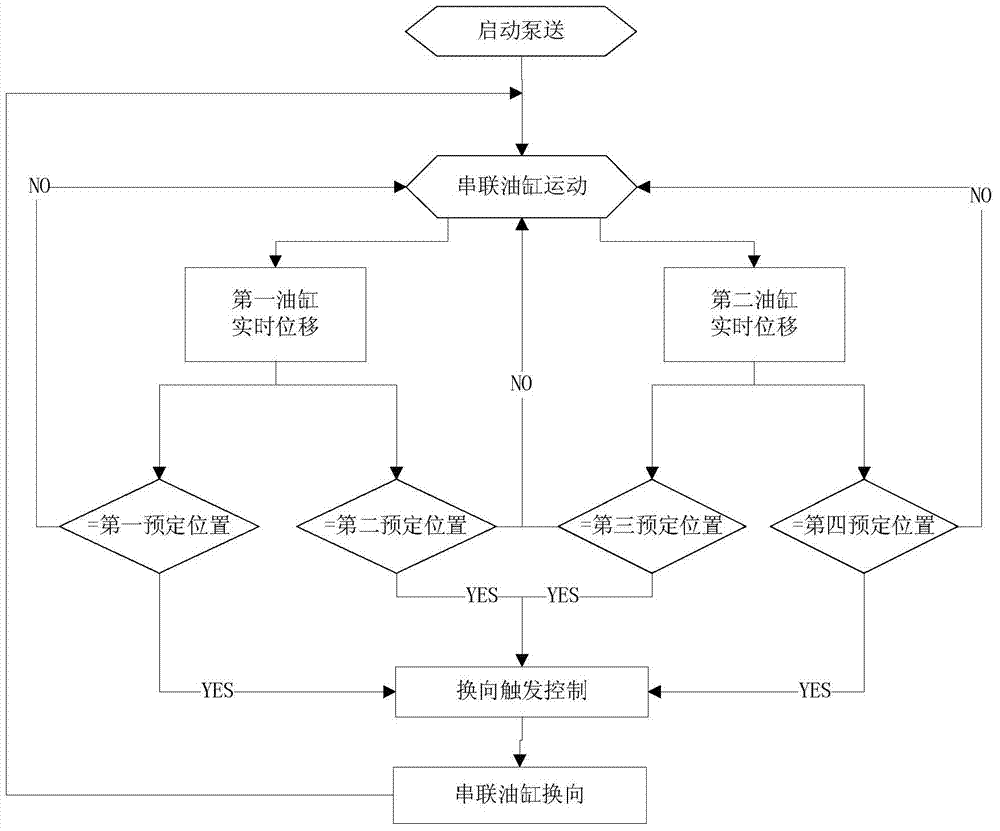

[0030] As a first aspect of the present invention, please refer to Figure 2 to Figure 5 , provides a method for controlling the reversing of oil cylinders connected in series, and more particularly relates to a method for controlling the reversing of pumping cylinders of piston concrete pumps.

[0031] The reversing control method includes: obtaining the position signal of the first piston 2 of the first oil cylinder 1; obtaining the position signal of the second piston 6 of the second oil cylinder 5; when the first piston 2 reaches the first predetermined position 3 or the second predetermined position When any condition of position 4 or the second piston 6 reaching the third predetermined position 7 and the fourth predetermined position 8 is met, the reversing of the series oil cylinder is triggered.

[0032]Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com