Positioning sliding trolley capable of automatically tracking central line of rail in real time

A track center and sliding trolley technology, which is applied in the field of equipment boundary detection in the rail transit area, can solve the problems of inability to achieve continuous inspection, obvious left and right shaking of the inspection template, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

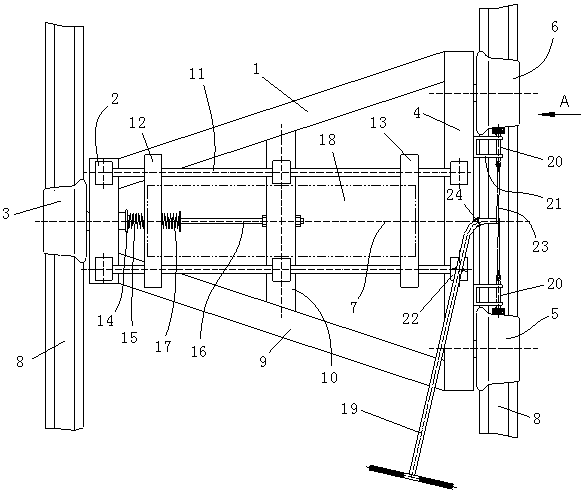

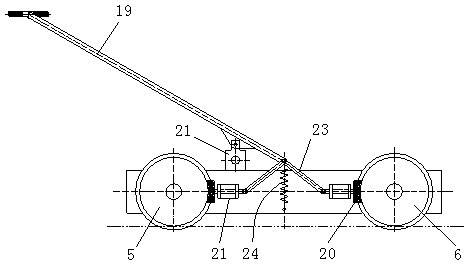

[0028] The specific implementation of the positioning trolley that automatically tracks the center line of the track in real time according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] See attached figure 1 , 2 The vehicle frame 1 of the positioning trolley of the automatic real-time tracking track center line is a plane isosceles trapezoidal structure, and a short beam 2 is arranged on the left side of the vehicle frame 1, and the first traveling wheel 3 is arranged on the short beam 2 through a rolling bearing, The wheel shaft of the first running wheel 3 can elastically move in a small range in its axial direction, and the second running wheel 5 and the third running wheel 6 are respectively arranged through rolling bearings at the front and rear ends of the long beam 4 of the vehicle frame 1. The wheel 3 is located on the symmetry axis 7 of the isosceles trapezoid, the second running wheel 5 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com