Composite bolt connection structure pin load distribution determination method in consideration of intervals and tightening torque

A technology of tightening torque and nail load distribution, which is applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

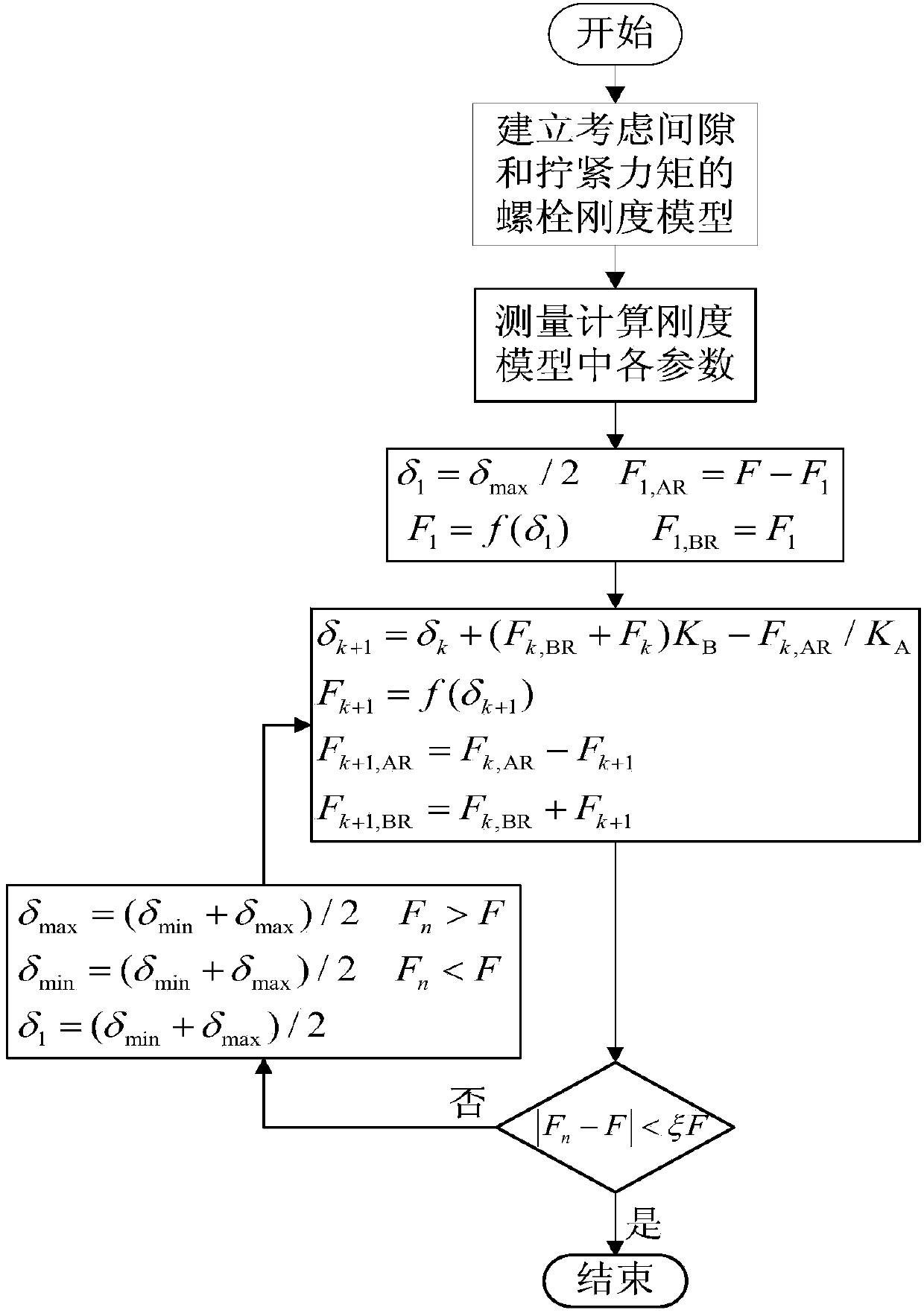

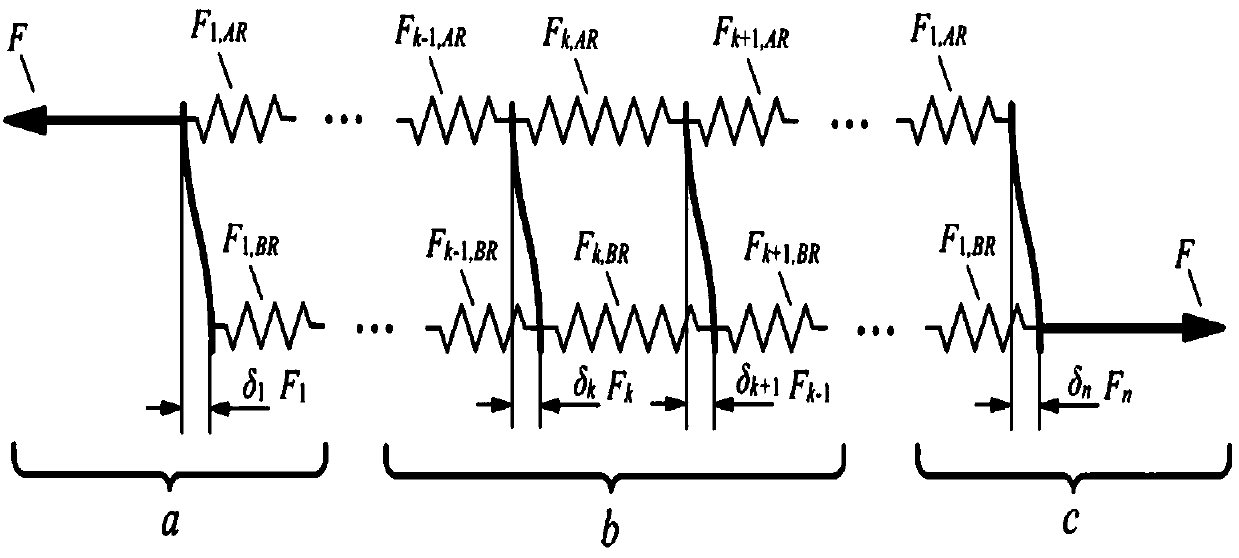

[0071] Such as figure 1 Shown, the concrete realization of the inventive method is:

[0072] 1. First establish the bolt stiffness model considering the gap and tightening torque,

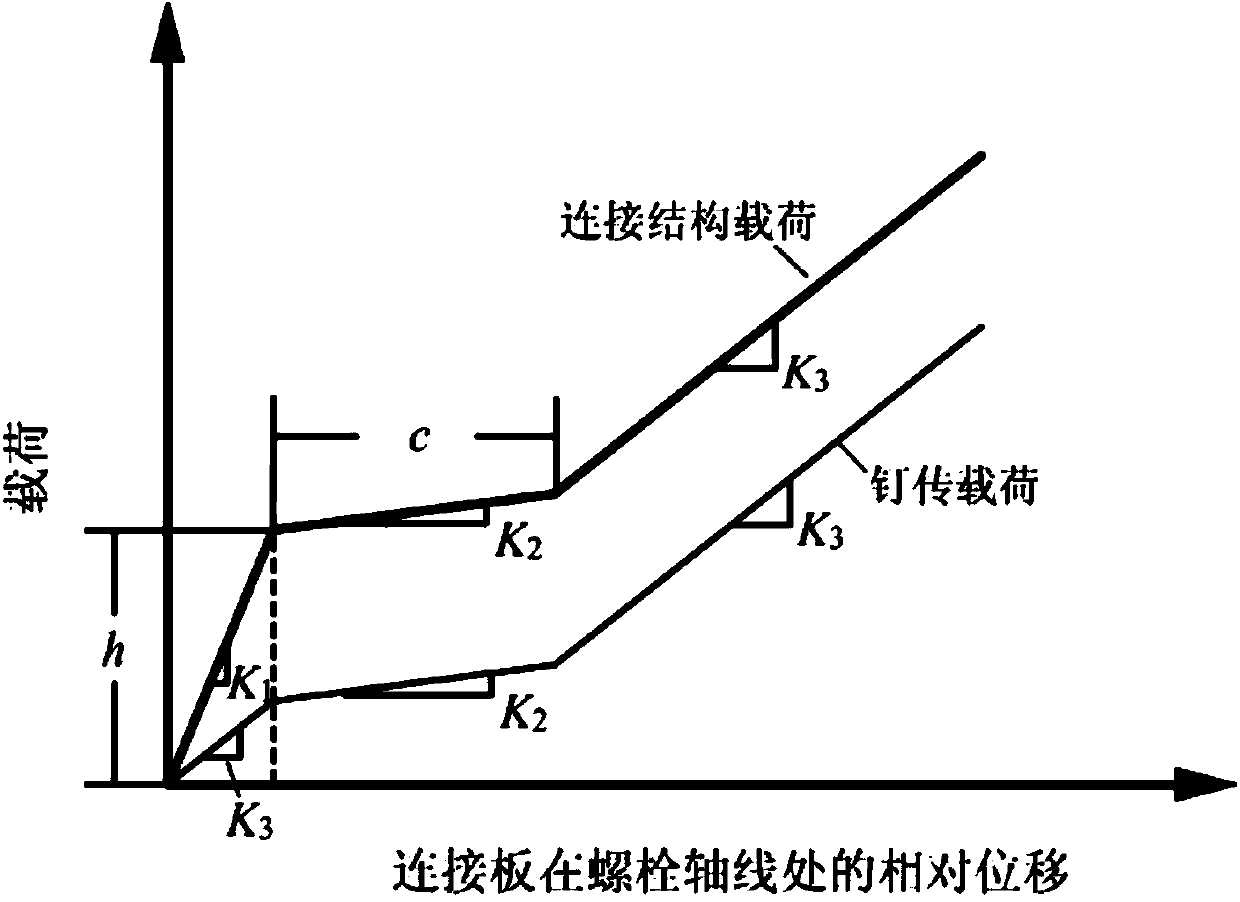

[0073] In the static friction section, the range of bolt deformation δ is:

[0074] δ ≤ D n n ( 1 + D m m ) [ K 3 + A c c + ( C n n ) C nn ] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com