Tensioning arrangement for a traction means of an elevator

A traction device and elevator technology, which is used in elevators in buildings, transportation and packaging, and lifting equipment in mines, etc. Fast, easy and reliable tensioning, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

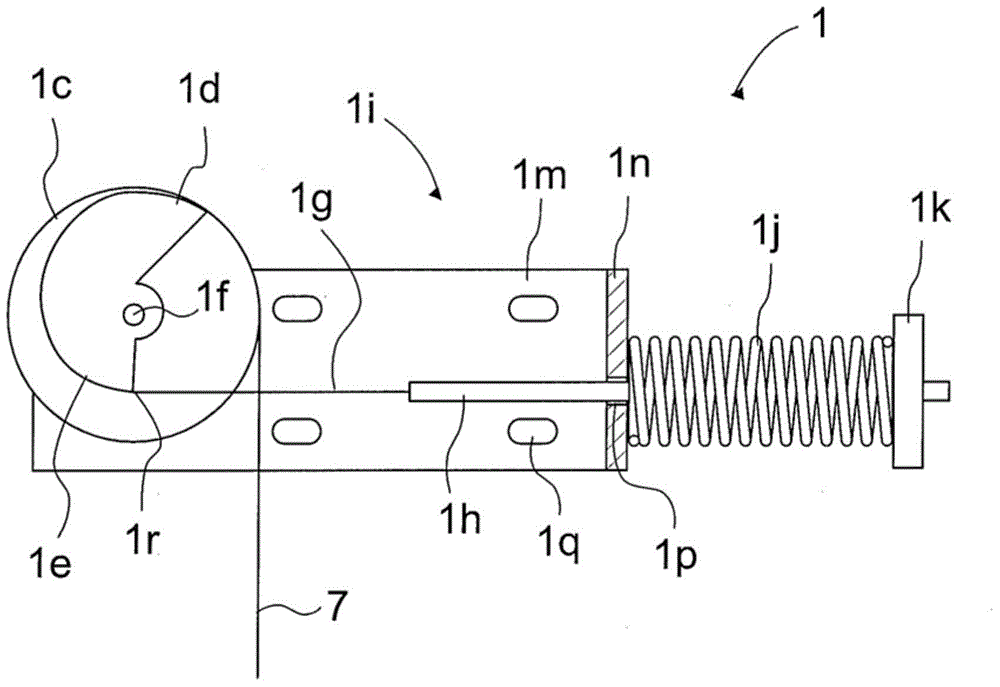

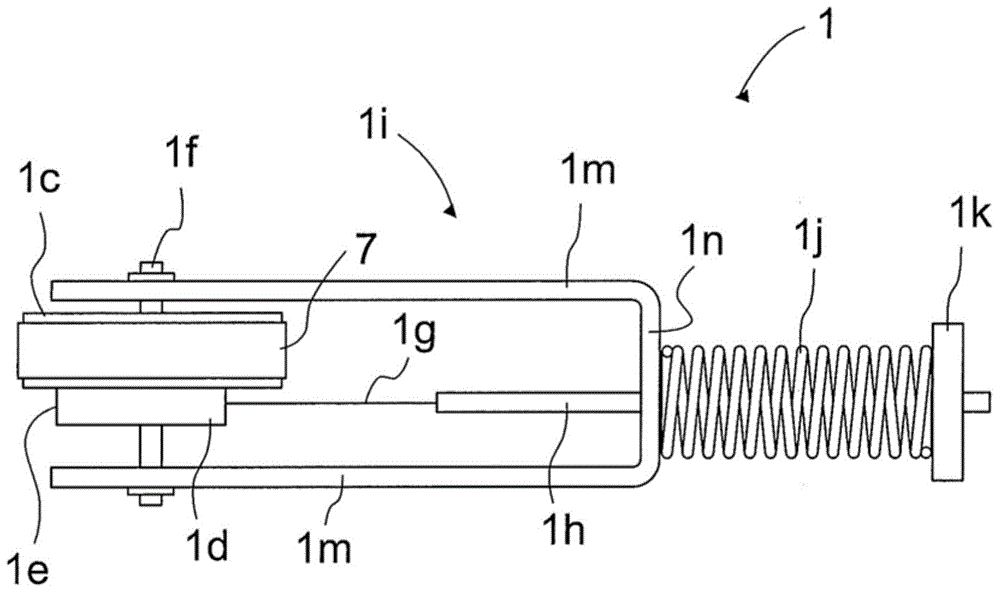

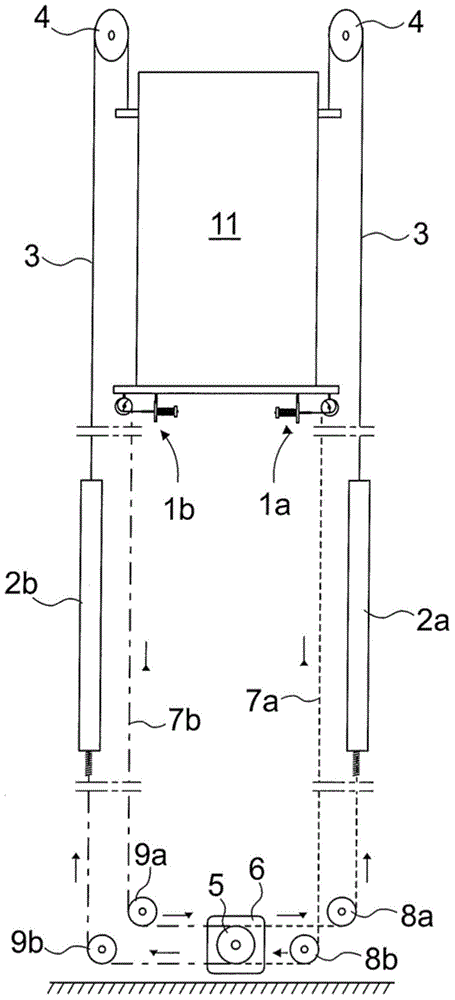

[0020] figure 1 with 2 A fixed arrangement of the traction device 7 of an elevator according to the invention is shown. The tensioning arrangement comprises at least one or more fixing means 1, 1a, 1b fixed from its frame part 1i to the bottom of the elevator car 11 or directly to the elevator car 11, Either in connection with the car hanger of the car, the fastening device is configured such that a tensioning of as constant a force as possible is achieved in the traction device 7 , 7 a , 7 b.

[0021] The fixing device 1, 1a, 1b comprises at least the aforementioned frame portion 1i, a roller 1c mounted on a shaft 1f of a bearing so as to rotate freely, an adjusting device 1d rotating together with the roller 1c, and a tensioning device 1g, which The free end of is tensioned into its proper position in the second end of the frame part 1i by means of a spring 1j. The frame portion 1i is, for example, a metal plate bent into a U shape as seen from above, which includes a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com