System and method for controlling spark timing when cylinders of an engine are deactivated to reduce noise and vibration

A spark timing and cylinder technology, applied in electrical control, automatic control, automatic control, etc., can solve problems such as increasing engine torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

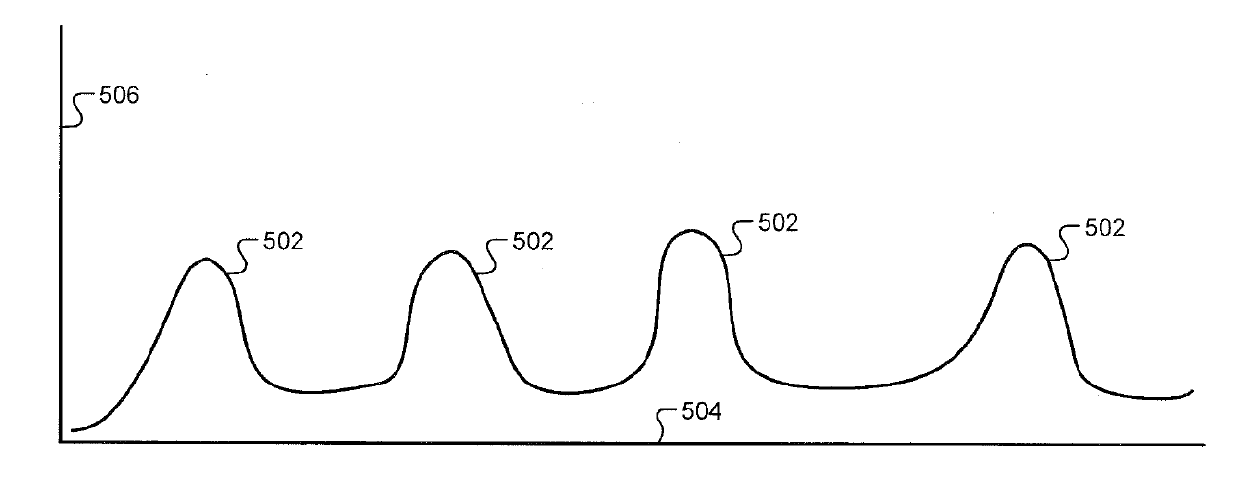

[0054] Engine vibrations are transmitted to the driver through powertrain mounts, bodywork, and driver interface components such as the driver's seat, steering wheels, and pedals. Engine vibration and vehicle body vibration derived from the engine vibration generate noise felt by the driver. When one or more cylinders of the engine are deactivated, the torque pulse of the cylinder that remains active may be close to the resonant frequency of the vehicle structure from powertrain mounts to driver interface components. Therefore, the driver may perceive an increase in vehicle noise and vibration.

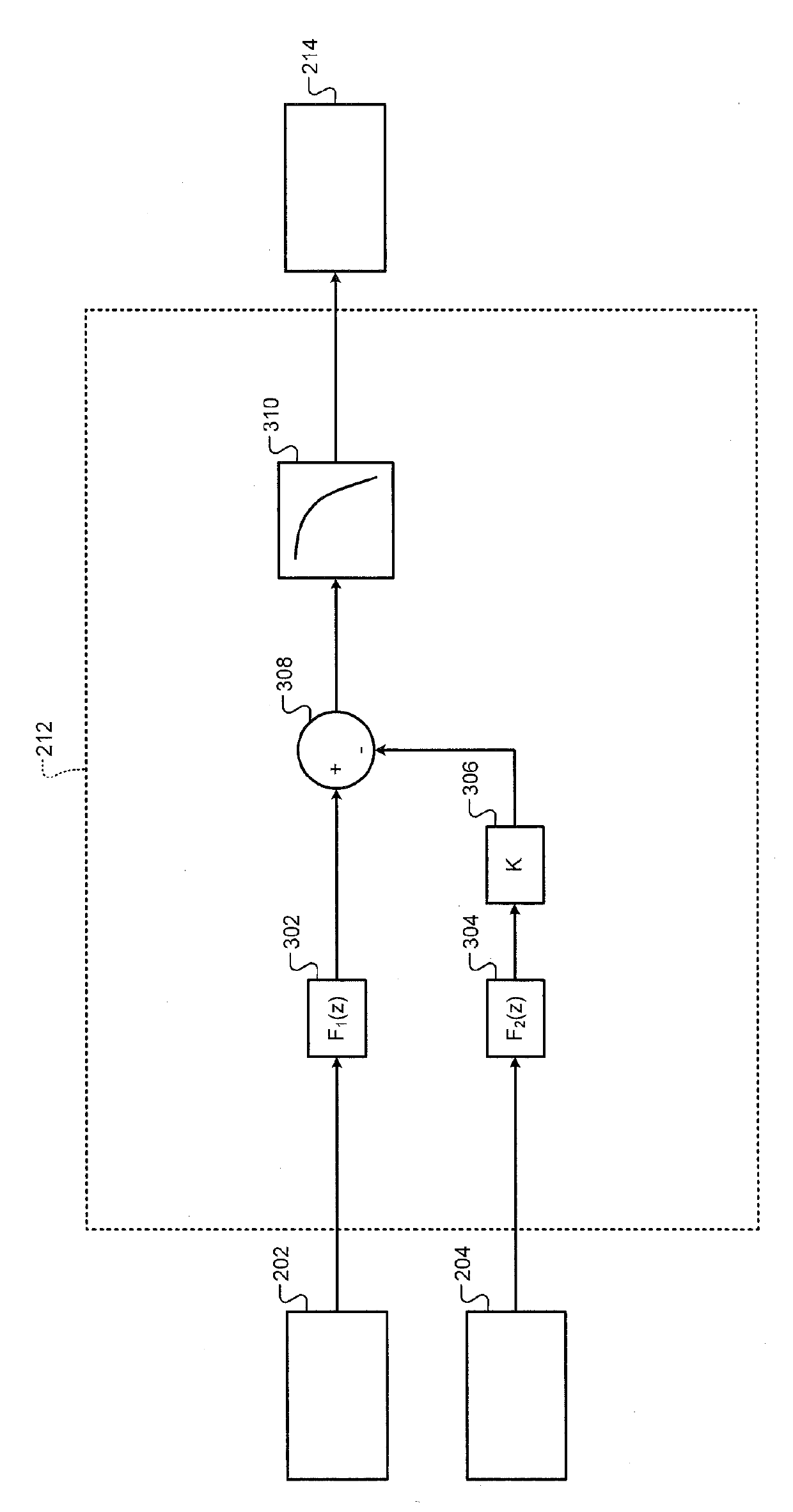

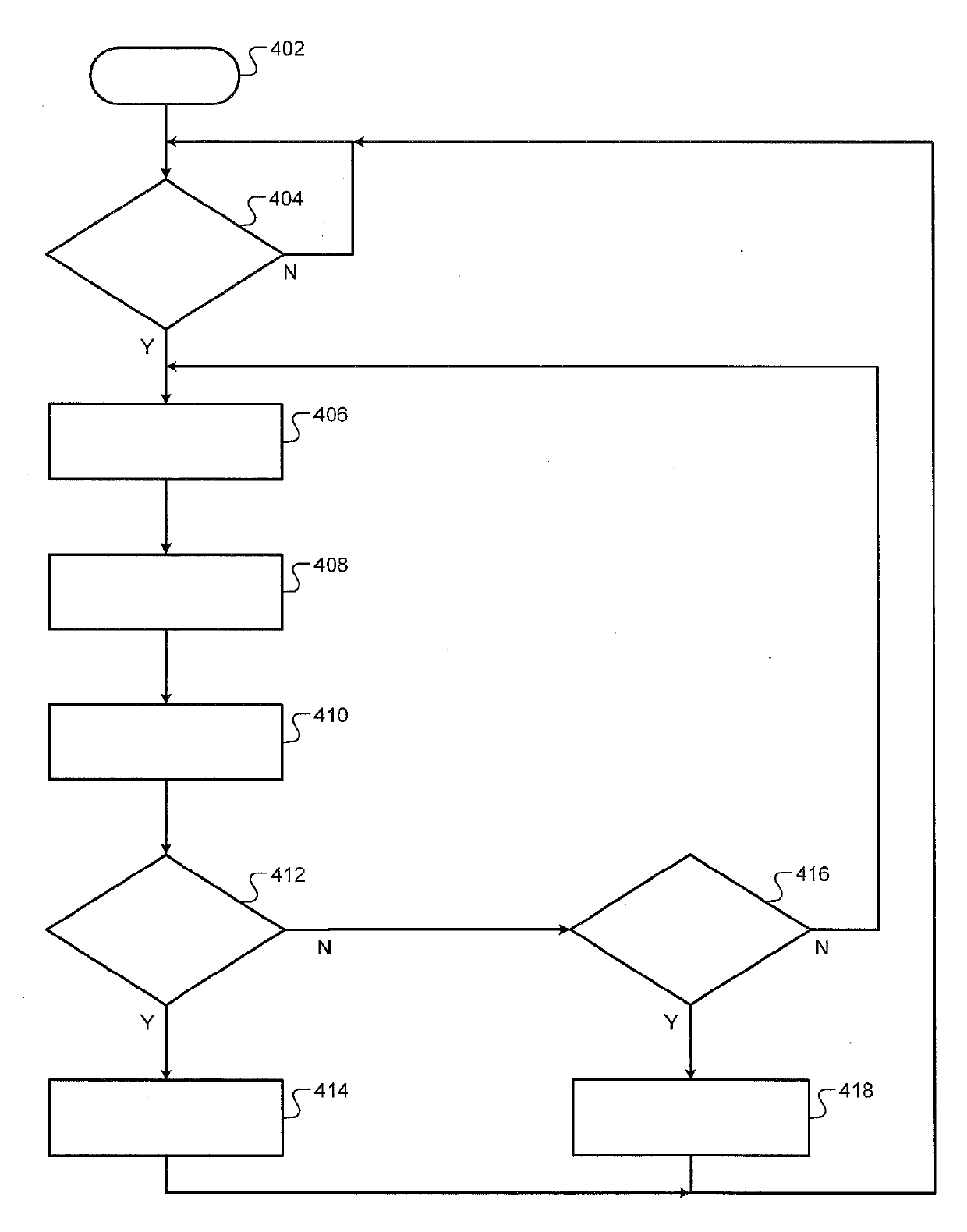

[0055] Systems and methods consistent with principles of the present disclosure adjust spark timing of one or more cylinders to reduce vehicle noise and vibration when one or more cylinders of an engine are deactivated. The spark timing of the one or more cylinders is adjusted to create a phase shift that cancels out the fundamental frequency of other cylinders in the engine. Thus, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap