Lower carrier roller support of belt conveyor

A technology for belt conveyors and roller brackets, which is applied in the direction of conveyor objects, rollers, transportation and packaging, etc., which can solve the problems of increasing labor intensity of employees, wear and tearing of idler brackets under belt conveyors, and reduce labor. The effect of reducing the workload and labor intensity, reducing belt chamfering, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

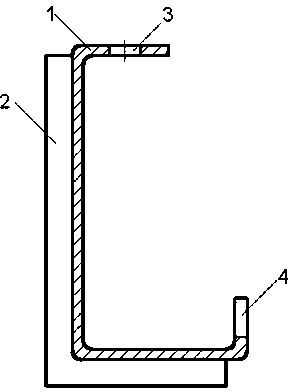

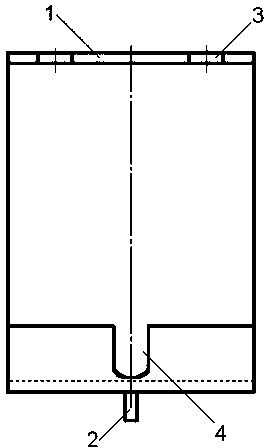

[0012] Example: Such as figure 1 , figure 2 As shown, the lower roller support 1 of the belt conveyor is designed as a concave bow, which is made of bent steel plates. If the bow structure is not enough to support the lower roller, the reinforcement plate 2 is welded and fixed on its outer side. Such as figure 2 , combined with figure 1 , the top of the support 1 is provided with two bolt holes 3, can use bolts to hang the lower part of the channel steel fixed on the belt support, the bottom of the support 1 is hook-shaped and is provided with a roller slot 4.

[0013] The present invention is used in pairs. When installing, the two concave surfaces face each other. Use bolts to pass through the bolt holes 3 above the bracket 1 to suspend and fix the bracket 1 to the lower part of the channel steel on the belt bracket. In the slot 4 of the idler roller, it can be used. When the belt is running, because the bracket 1 is designed as a concave bow shape, compared with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap