Combustion device, combustion method, and electric power-generating device and electric power-generating method using same

A combustion method and a technology of a combustion device, which are applied to combustion methods, burners for burning powder fuel, burners, etc., can solve the problems of difficulty in popularization, high initial investment, and increased operating costs, and achieve a reduction in combustion temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Embodiments of the present invention will be described below with reference to the drawings.

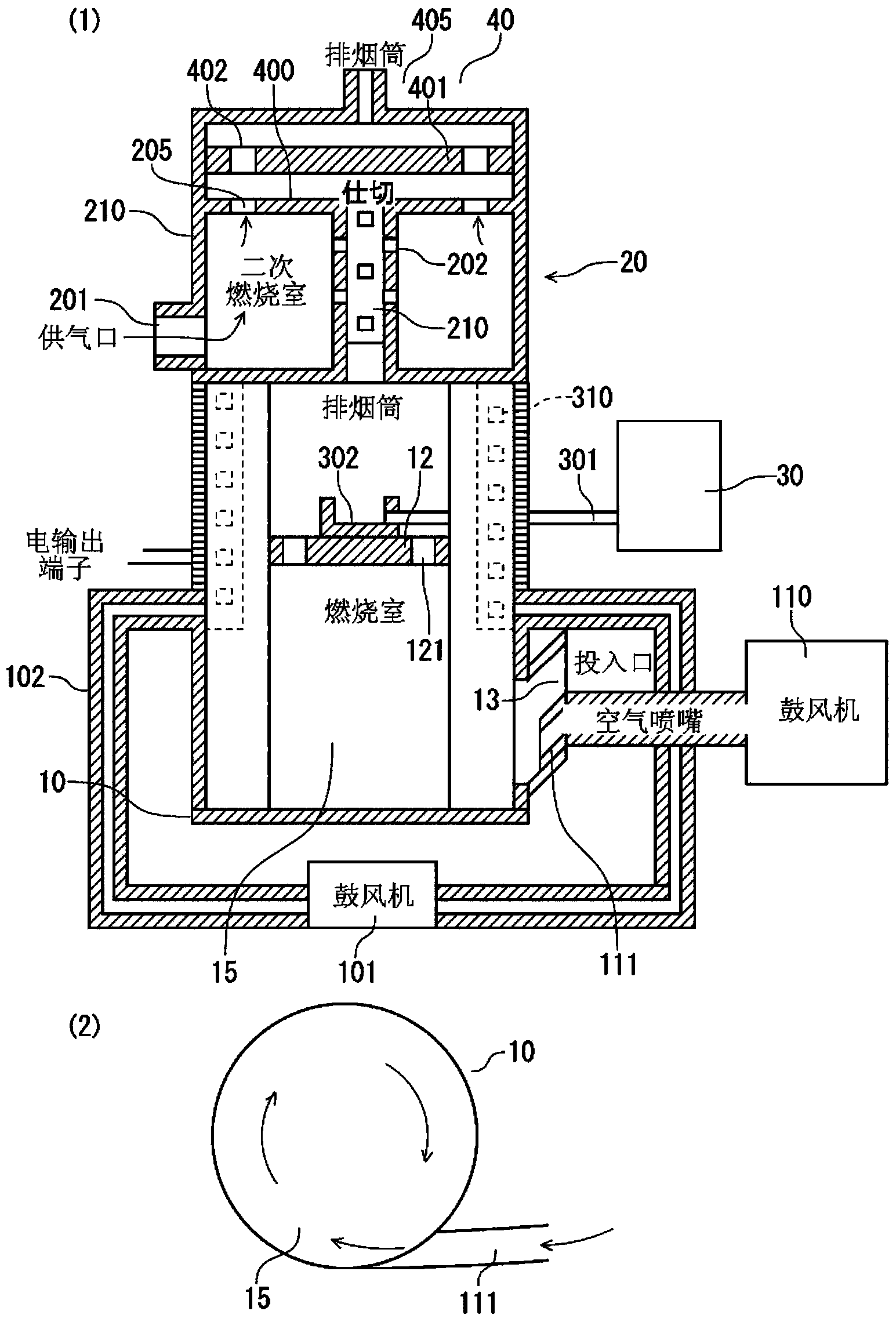

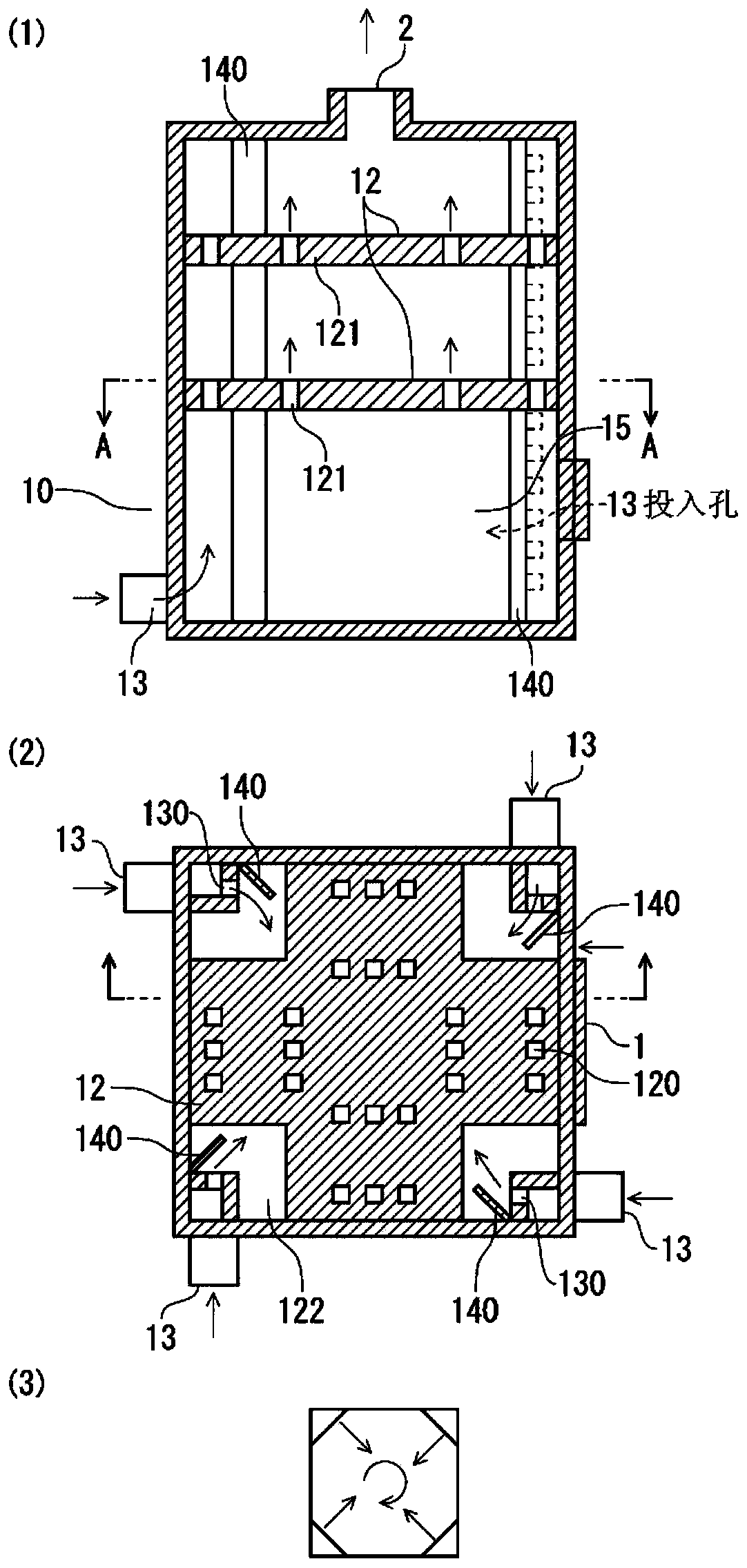

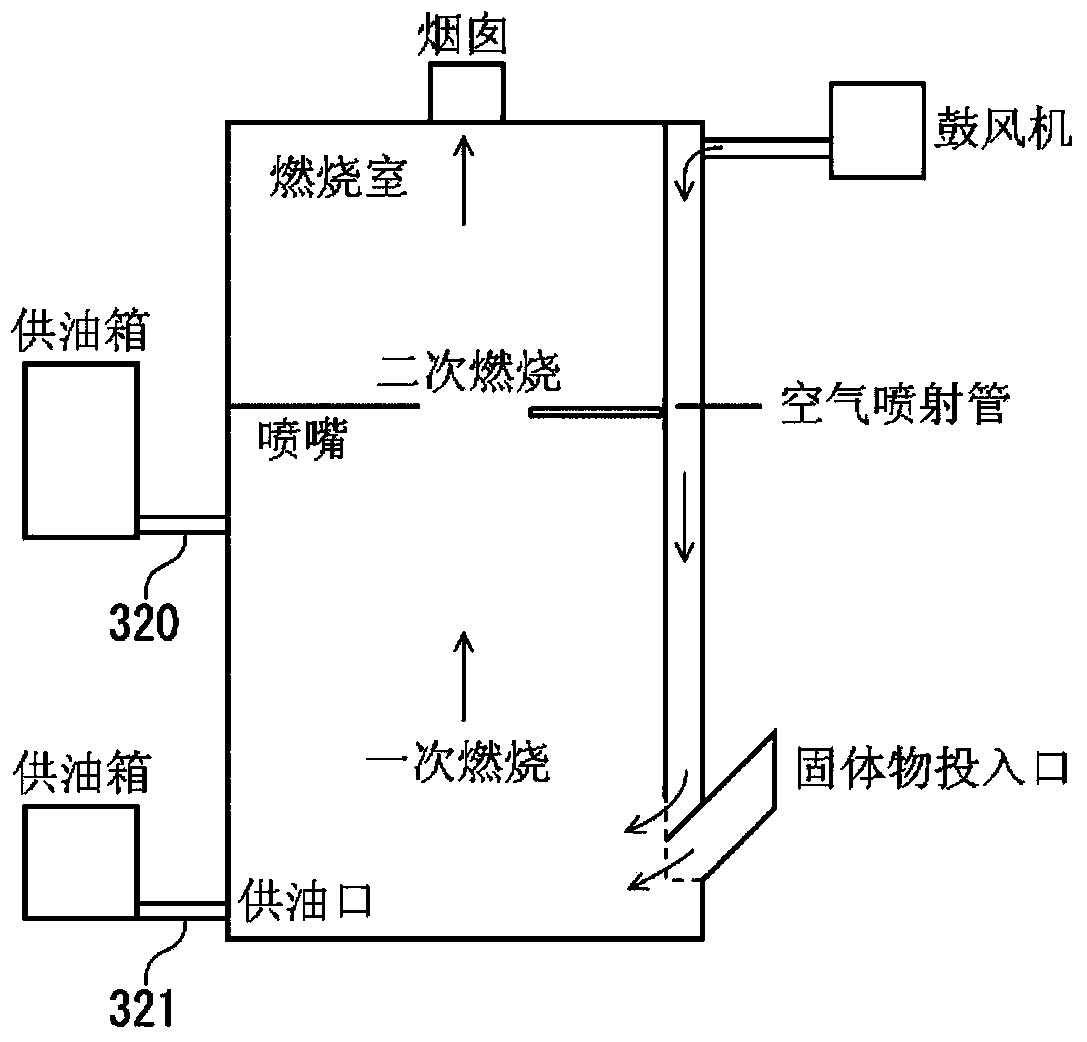

[0110] exist figure 1 , shows the combustion unit 10, the secondary combustion chamber 20, the air blower 110, the waste oil tank unit 30, etc. in the combustion device of the present invention.

[0111] Combustion device 10 such as figure 1 Combustion was performed as indicated.

[0112] An inlet 13 for burning objects such as solids is provided, and an air nozzle portion 111 is provided adjacent to the inlet 13 to guide the objects to be burned into the combustion chamber 15 .

[0113] In addition, in the present invention, any combustible gas can be used instead of air, but in the following examples, air is used as an example.

[0114] Solids can be completely and reliably charged by using the external air cut-off type charging device with a double door and a charging auxiliary chamber (not shown) on the outside of the combustion chamber.

[0115] That is, the air nozzl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap