Panel welding table

A welding table and panel technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of weak welding and large welding gap of the panel of the power distribution cabinet, and achieve simple structure, stable use and connection. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

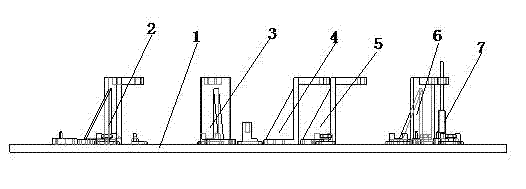

[0010] Example 1, such as figure 1 As shown, a panel welding station includes a base plate 1 and a welding positioning assembly arranged on the base plate 1, which is characterized in that: the welding positioning assembly includes from left to right: a first transverse positioning platform 2, a first longitudinal positioning The positioning platform 3 , the second lateral positioning platform 4 , the third lateral positioning platform 5 , the fourth lateral positioning platform 6 and the tail end positioning column 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap