A leaching experimental device for in-situ leaching mining uranium

An experimental device, the technology of uranium mining by in-situ leaching, is applied in the direction of mining fluid, earthwork drilling, measurement, etc. It can solve the problems that column leaching is difficult to provide leaching rate, uranium concentration, pore structure damage, and inability to simulate formation overburden pressure. Improve the guiding significance, quickly dissolve the balance, and maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

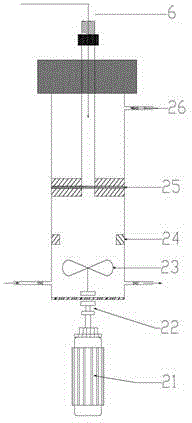

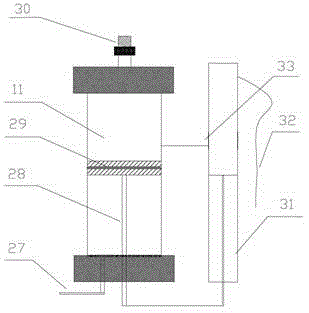

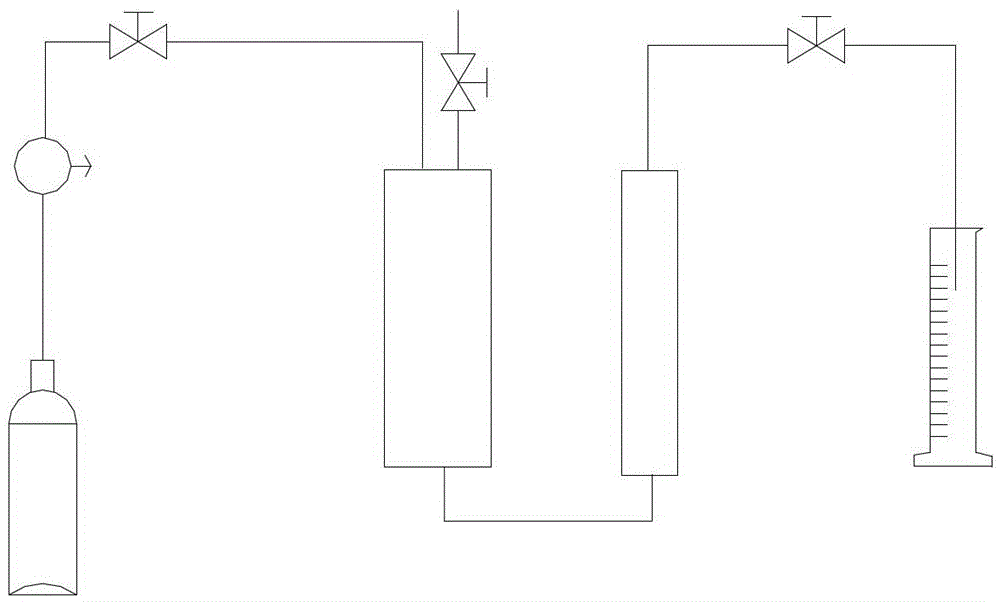

[0030] The present invention is an experimental leaching device for in-situ leaching mining uranium, which mainly includes a gas source, a high-pressure pressure reducing valve 3, a stop valve 4, a gas mass flow meter 5, a liquid inlet pipeline 6, a stirring container 7, a nitrogen cylinder 8, and a back pressure of the stirring container Valve 9, pneumatic valve 10, liquid injection intermediate container 11, intermediate container back pressure valve 12, plunger pump 13, pressure sensor, full diameter core holder 15, ring pressure pump 16, leaching back pressure valve 18, balance metering system 19 and computers 20, etc., of which:

[0031] Gas source intake part: The gas source includes oxygen gas source 1 and carbon dioxide gas source 2. The two gas sources respectively form the gas source intake part with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com