Clamp for charged replacement of tangent tower insulators

A live replacement, linear tower technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the time spent in conductors, not being identical, and physical exertion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

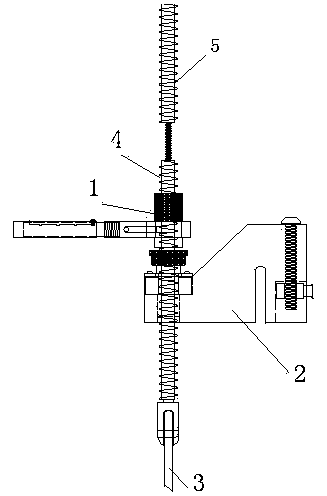

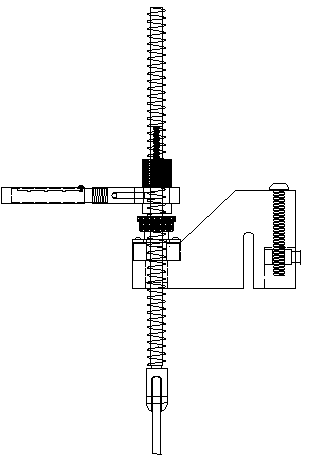

[0015] A jig for replacing insulators on a straight-line tower with electricity, including a cross-arm side jig, the cross-arm side jig includes a positioning steering shaft 1, a jig mold load horizontal block 2, and an insulating pull plate 3. The positioning steering shaft is provided with a universal screw mandrel 4, and the universal screw mandrel is provided with shaft holes distributed along its axial direction. This shaft hole is a threaded hole and also includes a connecting screw mandrel 5. The small end of the shaft hole of the screw rod and the large end having the same outer diameter and threads as the general screw rod, and the small end of the connecting screw rod are provided with threads matching the shaft hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com