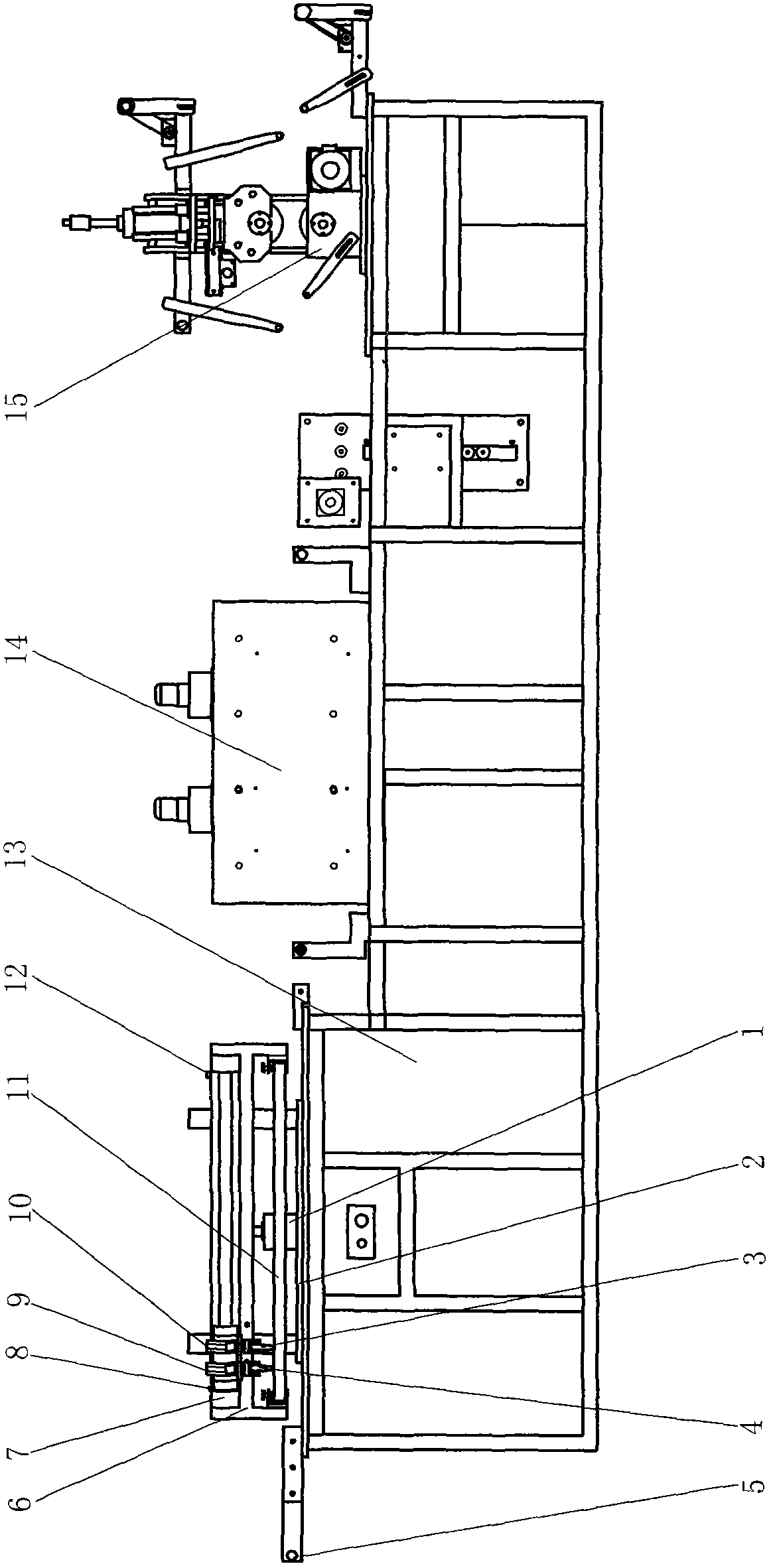

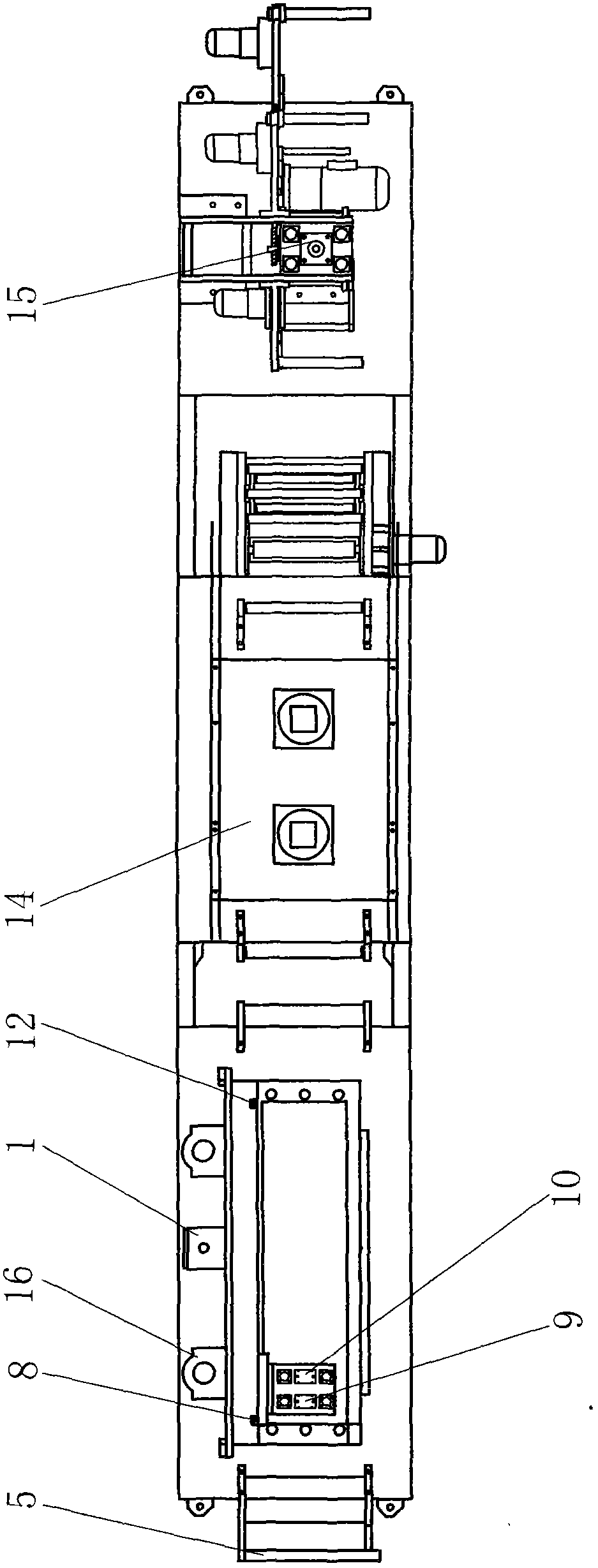

Screen printing mechanism of screen printing and gold stamping integrated machine

A technology of screen printing, bronzing and all-in-one machine, which is applied in printing presses, rotary printing presses, printing and other directions, and can solve problems such as single function of hot stamping machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, a screen printing workbench is installed on the bottom box 13, and a vertical screen printing support cylinder 1 is installed on the screen printing workbench. A silk screen support 6 is installed on the guide shaft of the screen printing support cylinder 1, and a screen plate is installed on the lower part of the screen printing support 6. 11. The left end of the screen printing support 6 is equipped with a rodless cylinder 7, the right side of the rodless cylinder 7 is equipped with a silk screen cylinder 9, and the screen printing scraper 4 is assembled on the lower guide shaft of the silk screen cylinder 9; Ink distributing cylinder 10, the ink distributing cylinder 10 is placed below the guide shaft to equip the ink distributing scraper 3; the rear side of the silk screen support 6 is equipped with a silk screen suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap