Multi-functional thermal printing machine

A thermal printer, multi-functional technology, applied in the field of printing and thermal printing machinery, can solve the problem of single function of thermal printer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

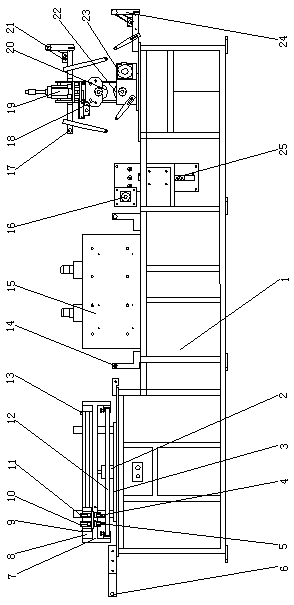

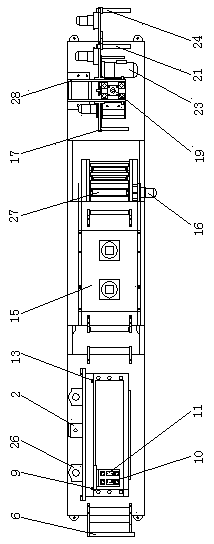

[0015] As shown in the figure, a screen printing mechanism is installed on the upper left of the bottom box 1, a thermal printing mechanism is installed on the right, an oven 15 is installed in the middle, a servo motor 16 is installed on the right side of the oven 15, and a servo motor 16 is installed on the right side. Strip driving roller 27 (top view) is housed, and the front of strip driving roller 27 is equipped with strip storage material slide block.

[0016] The screen printing mechanism on the left includes a screen printing workbench on the bottom box 1, a vertical screen printing support cylinder 2 on the screen printing workbench, a silk screen support 7 on the guide shaft of the screen printing support cylinder 2, and a silk screen support 7 at the bottom of the screen printing support. Screen printing plate 12, rodless cylinder 8 is equip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap