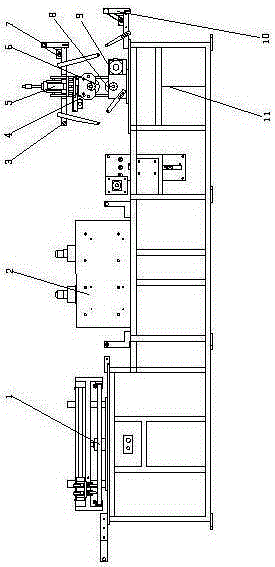

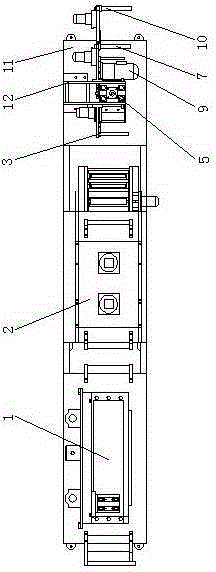

Hot printing mechanism of all-in-one machine

An all-in-one machine and thermal printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problem of single function of thermal printing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, a heat printing frame 12 is installed on the rear part of the upper right side of the bottom box 11, a heat printing cylinder 5 is installed on the upper part of the heat printing frame 12, a beam is installed on the lower part of the heat printing cylinder 5, and a storage box is installed on the left end of the beam. Foil device 3, the right end of the beam is equipped with a foil receiving device 7; the lower guide shaft of the thermal printing cylinder 5 is equipped with a thermal printing head 4, the lower part of the thermal printing head 4 is equipped with a thermal printing roller 6, and the lower part of the thermal printing roller 6 is installed There is a thermal printing drive roller 8, and the right side of the thermal printing driving roller 8 is equipped with a thermal printing motor 9. The left side above t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap