Arrangement structure and method of sensors in buffer material multi-field coupling experiment bench

A technology of experimental bench and layout structure, which is applied in the direction of material inspection products, analytical materials, instruments, etc., and can solve the problems of long half-life, high radioactivity, and high heat release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The arrangement structure and method of sensors in a buffer material multi-field coupling test bench provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

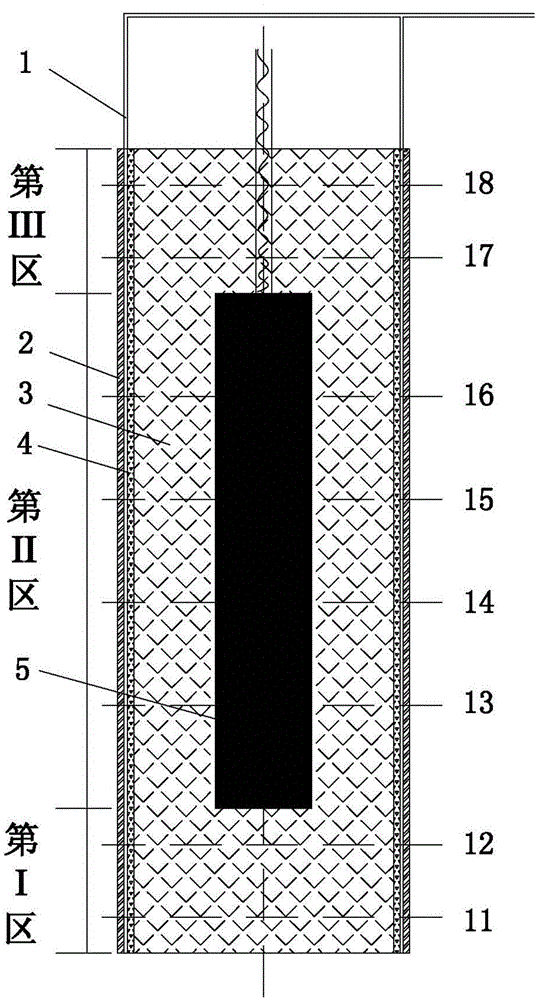

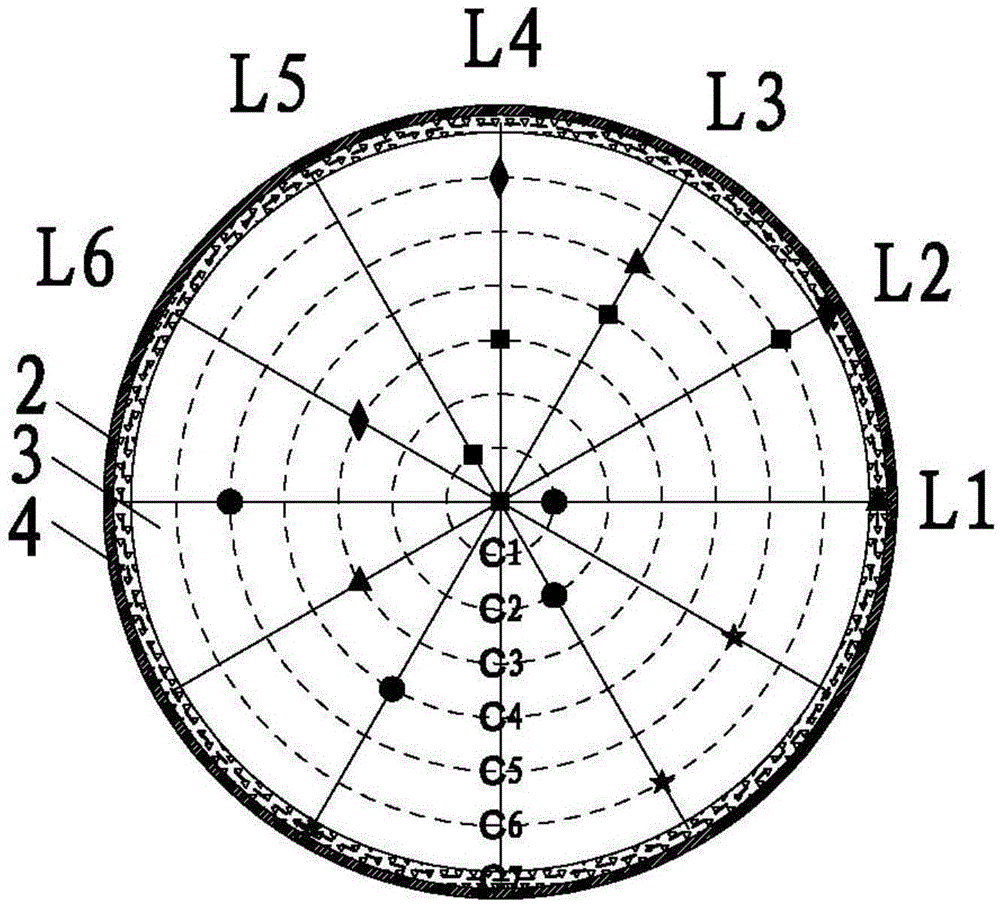

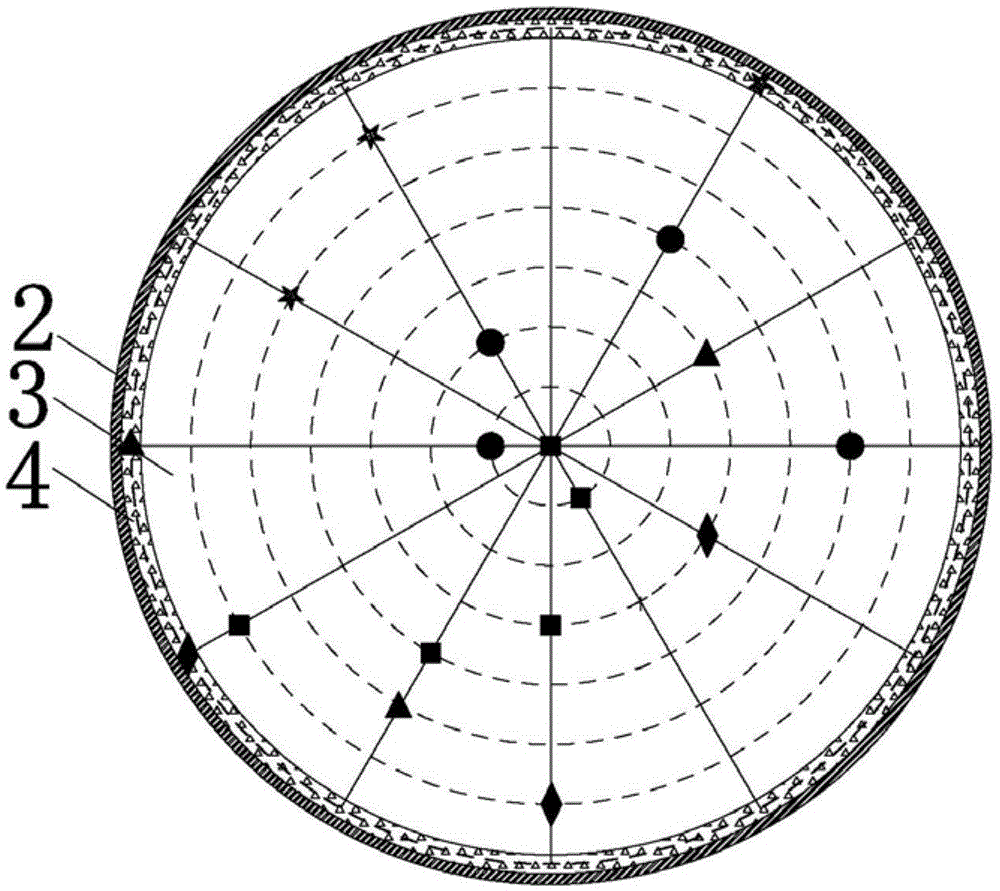

[0035] figure 1 It is a schematic diagram of the monitoring area and monitoring layer distribution of the buffer material multi-field coupling experiment bench. like figure 1 As shown, according to the current conceptual design of geological disposal of high-level radioactive waste in my country, the buffer material multi-field coupling test bench generally includes a vertical test bench cavity 2, a bentonite block layer 3, a heater 5, a water injection device 1, and a data acquisition system, etc. Part is an axisymmetric structure. Among them, the heater 5 in the center is used to simulate the decay heat release phenomenon of the high-level radioactive waste disposal tank, and the water injection pipe 1 placed around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com