Methods and apparatus for curing retreaded tires

A technology for retreading tires and tires, applied in the direction of transportation and packaging, tire parts, tire tread/tread pattern, etc., can solve the problems of complex compression, unevenness under the tread, becoming fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

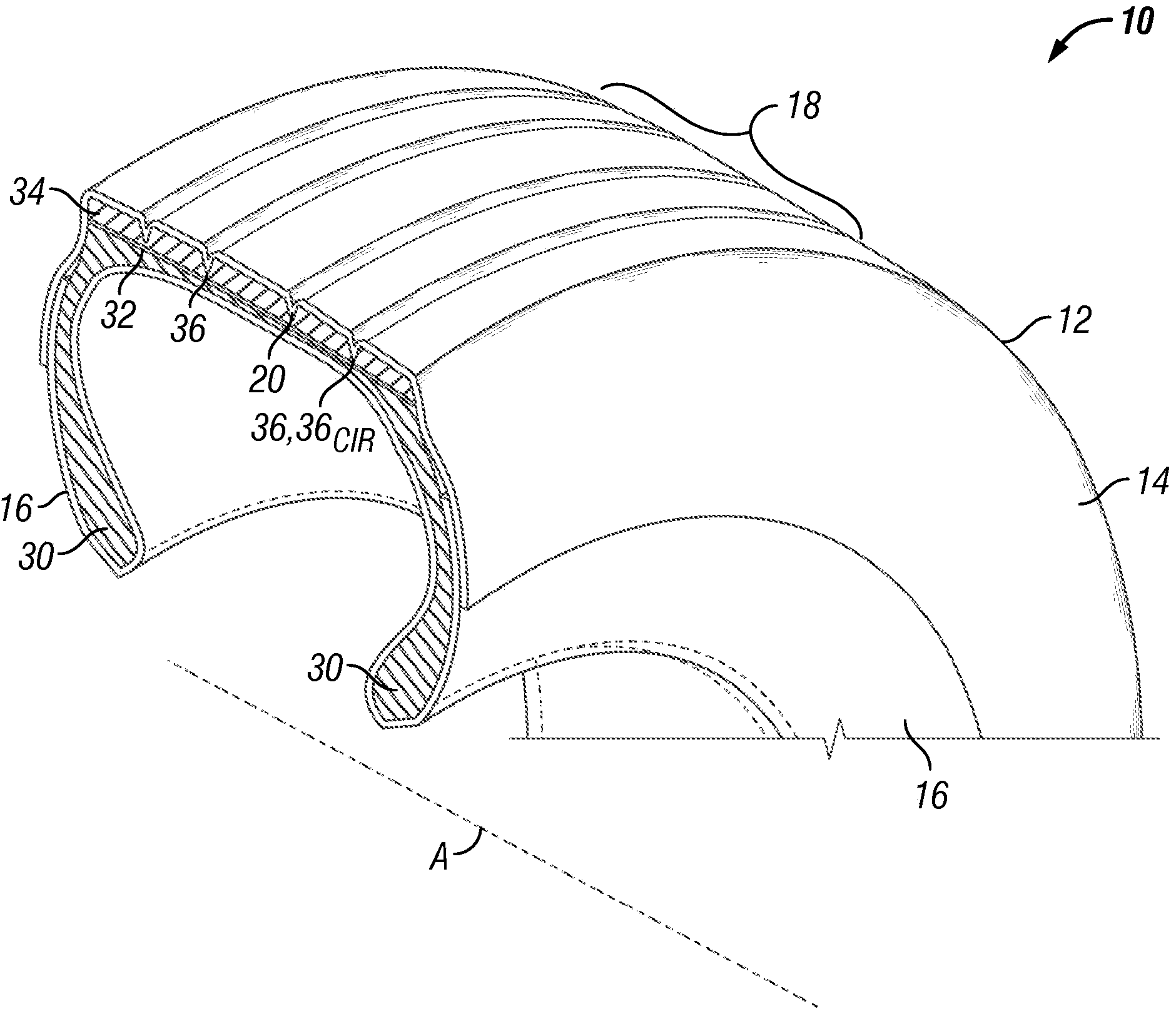

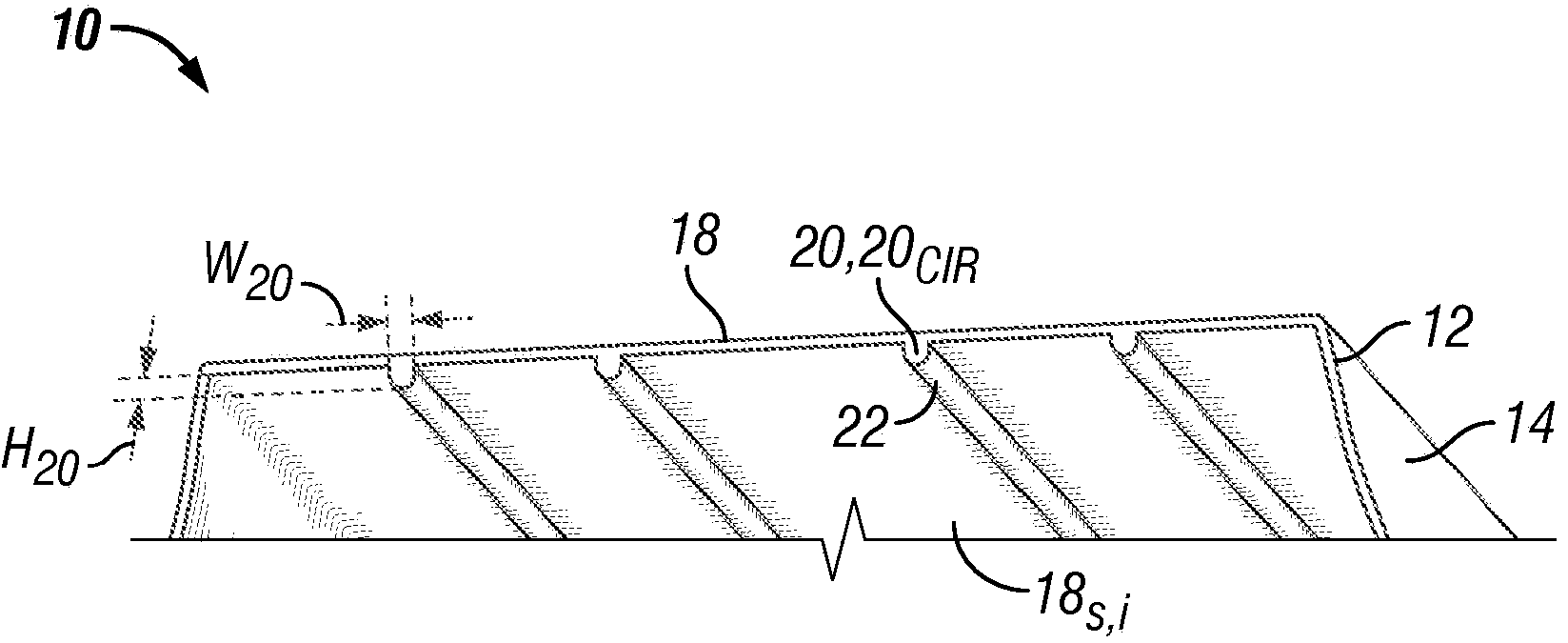

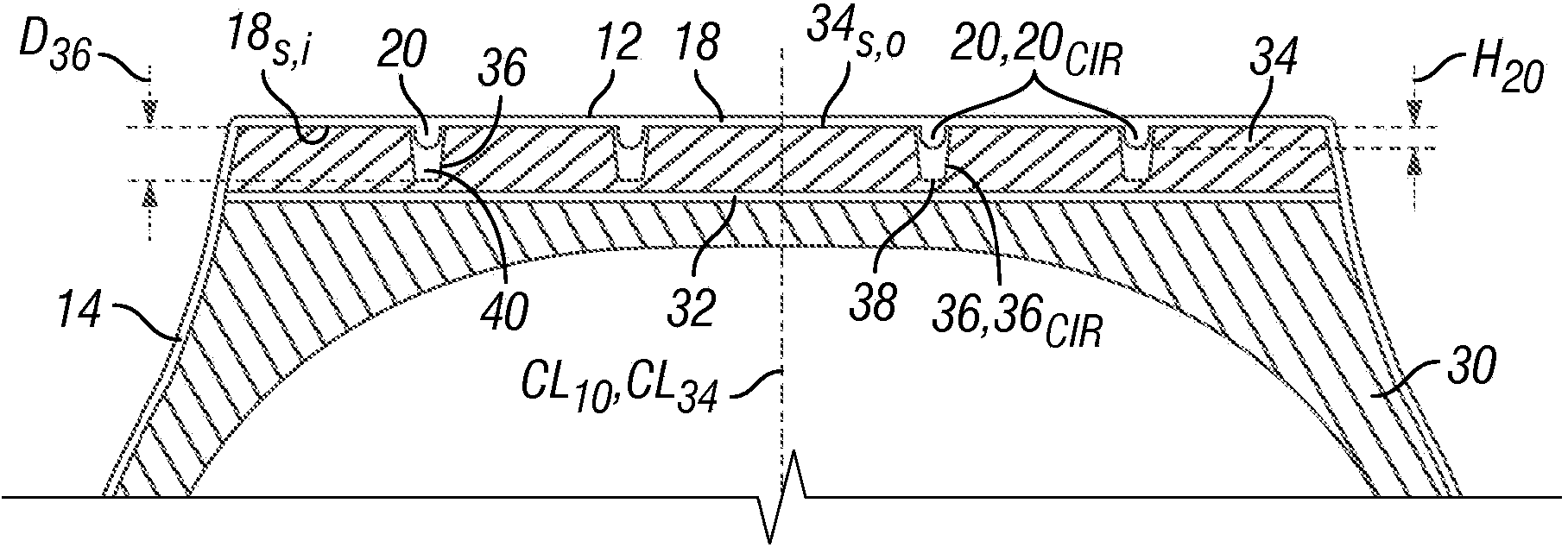

[0022] Certain embodiments of the present invention provide for maintaining the shape and volume of cavities positioned along the outer surface of the tread, constraining the tread in a desired arrangement relative to the tire carcass (i.e., outer tire), and / or when forming a retreaded tire. Methods and apparatus for constraining a curing membrane in a desired arrangement relative to a tire tread. By employing such methods and apparatus, the shape, volume, and arrangement of cavities located along the outer surface of the tread are better preserved. For this reason, the width of the tread is better maintained when the shape and / or volume of the void is generally preserved and stabilized. In particular embodiments, such methods and apparatus maintain tread grooves in an open arrangement and / or in a desired open shape. In addition, such methods and apparatus assist in maintaining the bottom of any such recess in a desired arrangement, such as substantially preventing any substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com