Multi-stage drop test machine

A drop test and platform technology, applied in the direction of impact test, machine/structural component test, measuring device, etc., can solve the problem of not being able to meet the multiple drop tests of fragile samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

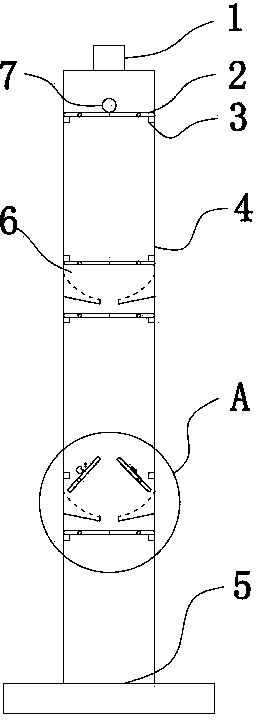

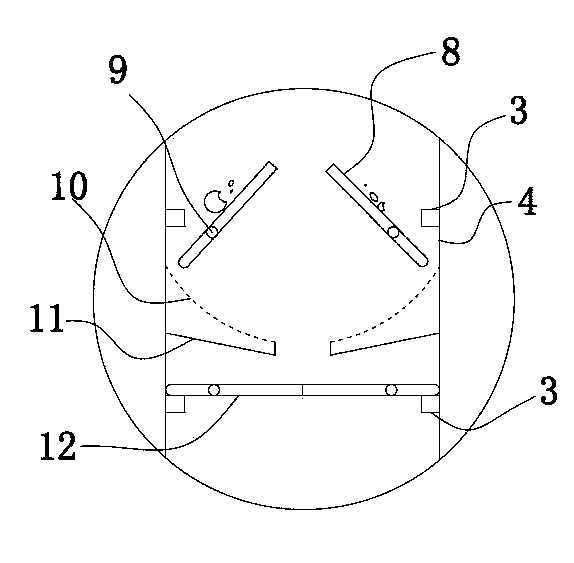

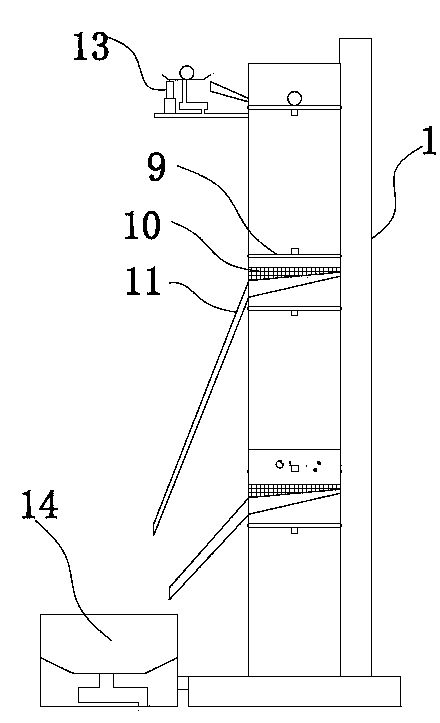

[0022] Example: A three-stage drop test machine, such as figure 1 , image 3 Shown. The device includes a bracket 1, the upper surface of the bottom of the bracket is the drop floor 5. One side of the bracket is provided with a vertical pole, and the top of the pole is provided with a lifting platform 2 that can be opened and closed. The lifting platform 2 is symmetrical from the left and the right. The plate body is composed of the plate body, the plate body pivot axis is located in the middle of the plate body, the middle part of the lifting platform, that is, the junction of the two plates, can be opened downwards, and a stopper is provided under the outer sides of the two plates to prevent the lifting platform from opening in reverse. The block 3 and the stop block 3 are arranged on the side baffles 4 on both sides of the lifting platform.

[0023] Two conversion layers 6 are arranged at equal intervals between the lifting platform and the falling floor. Side baffles 4 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com