Anti-misoperation type cutting stapler

An anti-misoperation and stapler technology, applied in the field of medical devices, can solve the problems of false firing of empty staple cartridges, wounding people, etc., and achieve the effects of stable and accurate staple formation, slow speed and excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

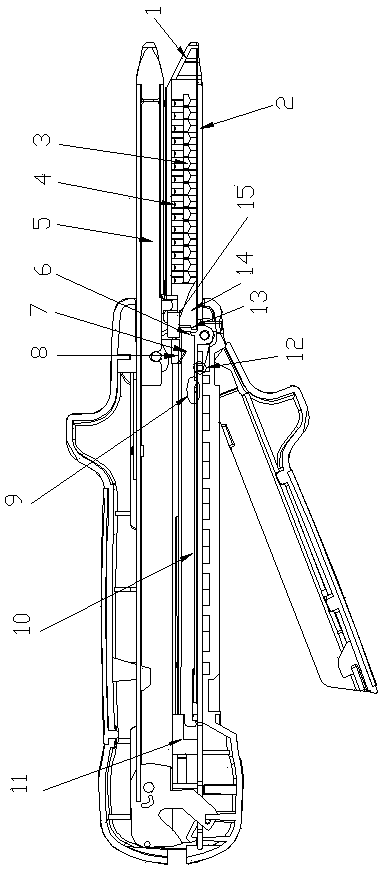

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

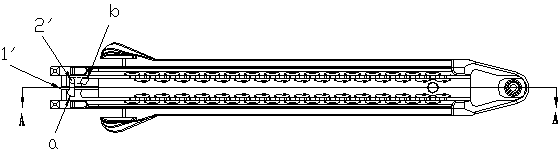

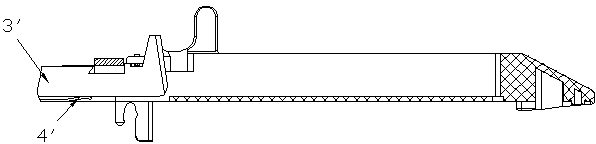

[0017] The anti-misoperation type cutting stapler includes an abutment seat 5, a staple cartridge 1 with a number of staples inside, a bracket 2 for supporting the components, and a staple pushing device for pushing the staples 4 in the staple cartridge. The nail pushing device includes a push piece 10, a nail pushing sled 14, and a nail pushing grain 3. The nail pushing grain 3 inside the staple cartridge 1 directly acts on the staples 4, and the nail pushing skid 14 is initially located at the initial position of the nail cartridge, that is, image 3 In the position where the push nail sled 14 is located, its front part pushes the push nail grain 3, and the rear part is provided with a boss 13 that bridges the groove 6 at the front end of the push piece 10. A locking boss 9 is provided on the upper part, and a card slot 12 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com