Novel two-dimensional adjustable contracting nozzle

A nozzle and a new type of technology, applied in the field of binary adjustable convergent nozzles, can solve the problems of not being able to block the hot end components at the front end, affect the adjustment range of the nozzle throat, increase the structural size of the nozzle, etc., and achieve the function of making up for the stealth Defects, good invisibility, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

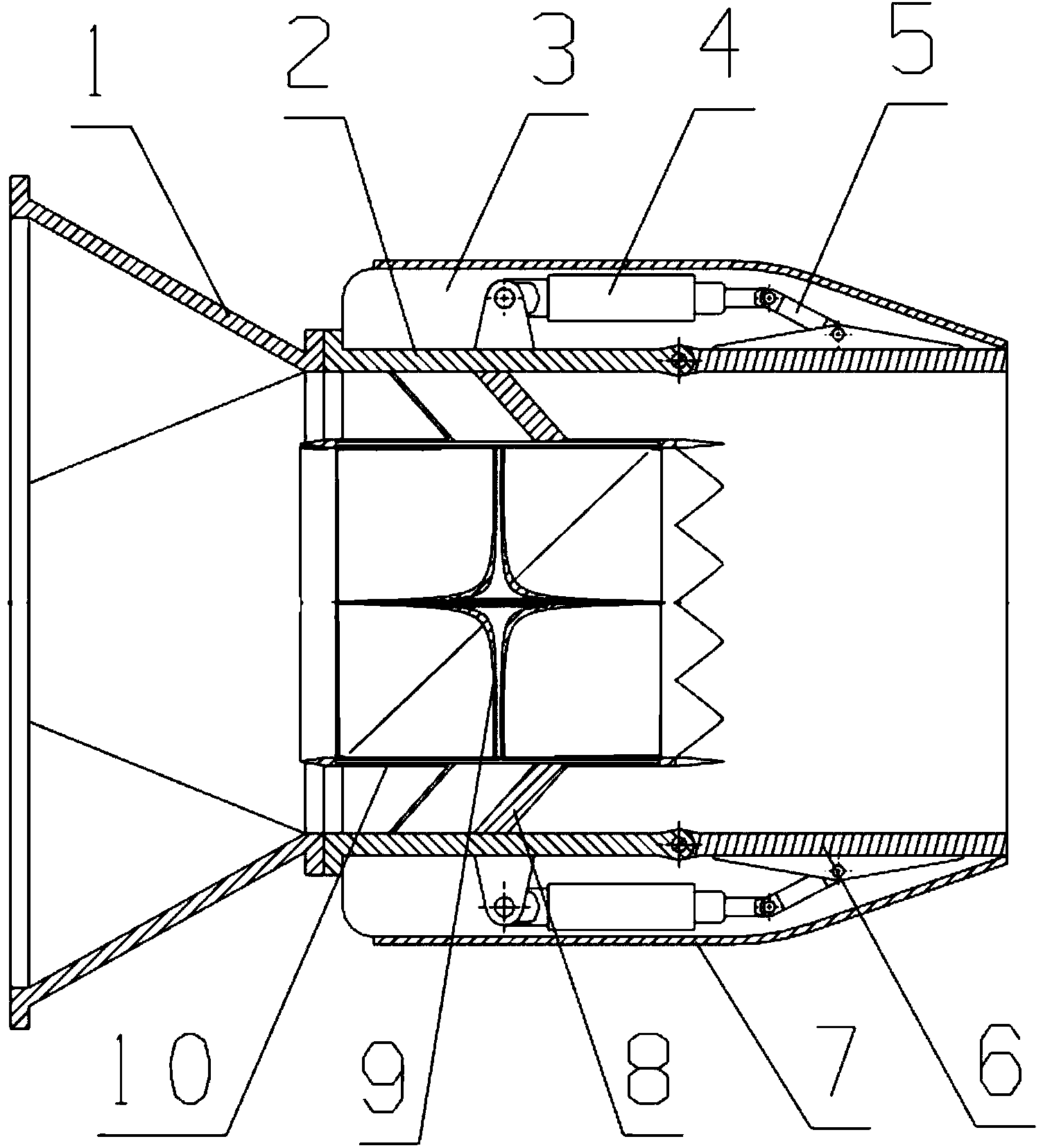

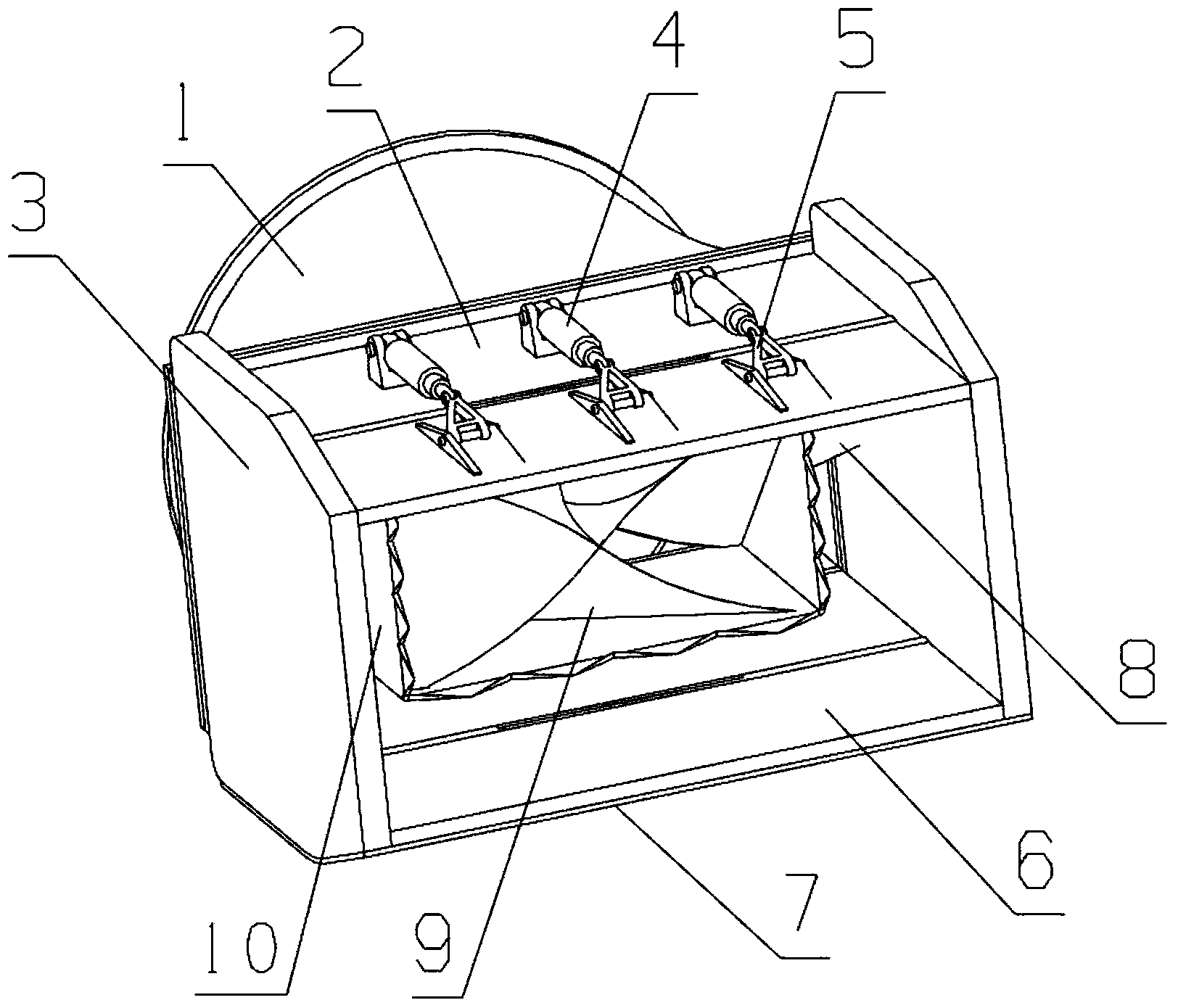

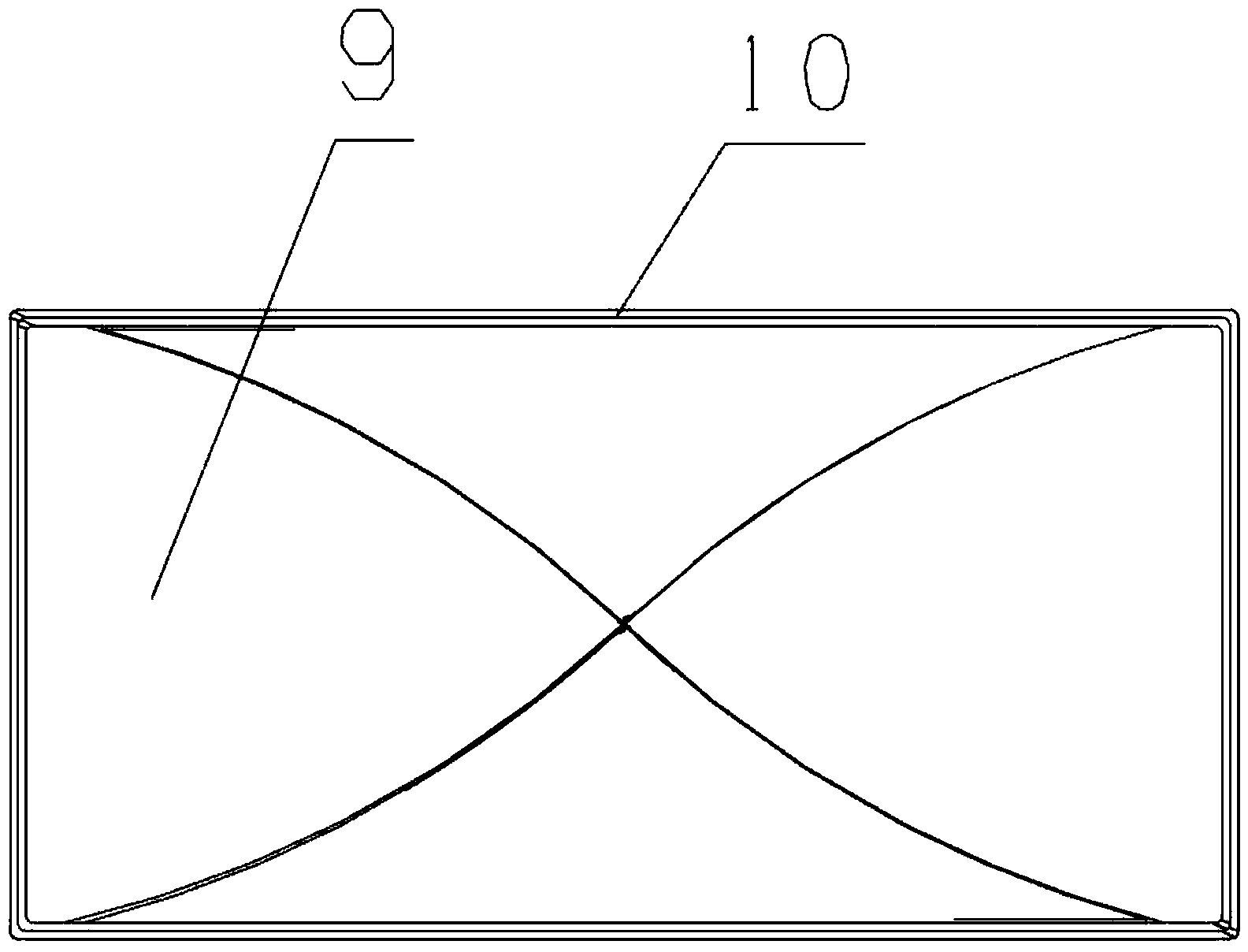

[0027] A new type of binary adjustable convergent nozzle, which is characterized in that it includes a circular rotating square cylinder body 1, a fixed flow channel plate 2, a side wall 3, an actuator 4, a connecting rod mechanism 5, a convergent adjustment plate 6, a nozzle Tube cover 7, bracket 8, shielding swirl leaf-shaped structure 9 and thin-walled square structure 10, wherein:

[0028] The front end of the rounded square cylinder 1 is connected to the engine as a supporting member for the entire nozzle;

[0029] The convergence adjustment mechanism is composed of an actuator 4, a link mechanism 5 and a convergence adjustment plate 6, wherein the actuator 4 is arranged along the axis of the convergence adjustment plate, and the front end is connected to the cylinder body 1 or the fixed flow channel plate through a mechanical connection. 2. On the outer wall, the rear end is connected to the link mechanism 5 through a rotating pair; the front end of the convergence adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com