Binary vector spraying pipe capable of realizing S-bent shading function

A vector nozzle and functional technology, applied in the field of binary vector nozzles, can solve the problems that high-temperature components cannot be completely blocked, poor infrared stealth performance, and the length of the expansion section cannot be adjusted, and achieve good infrared stealth performance and stealth Good and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

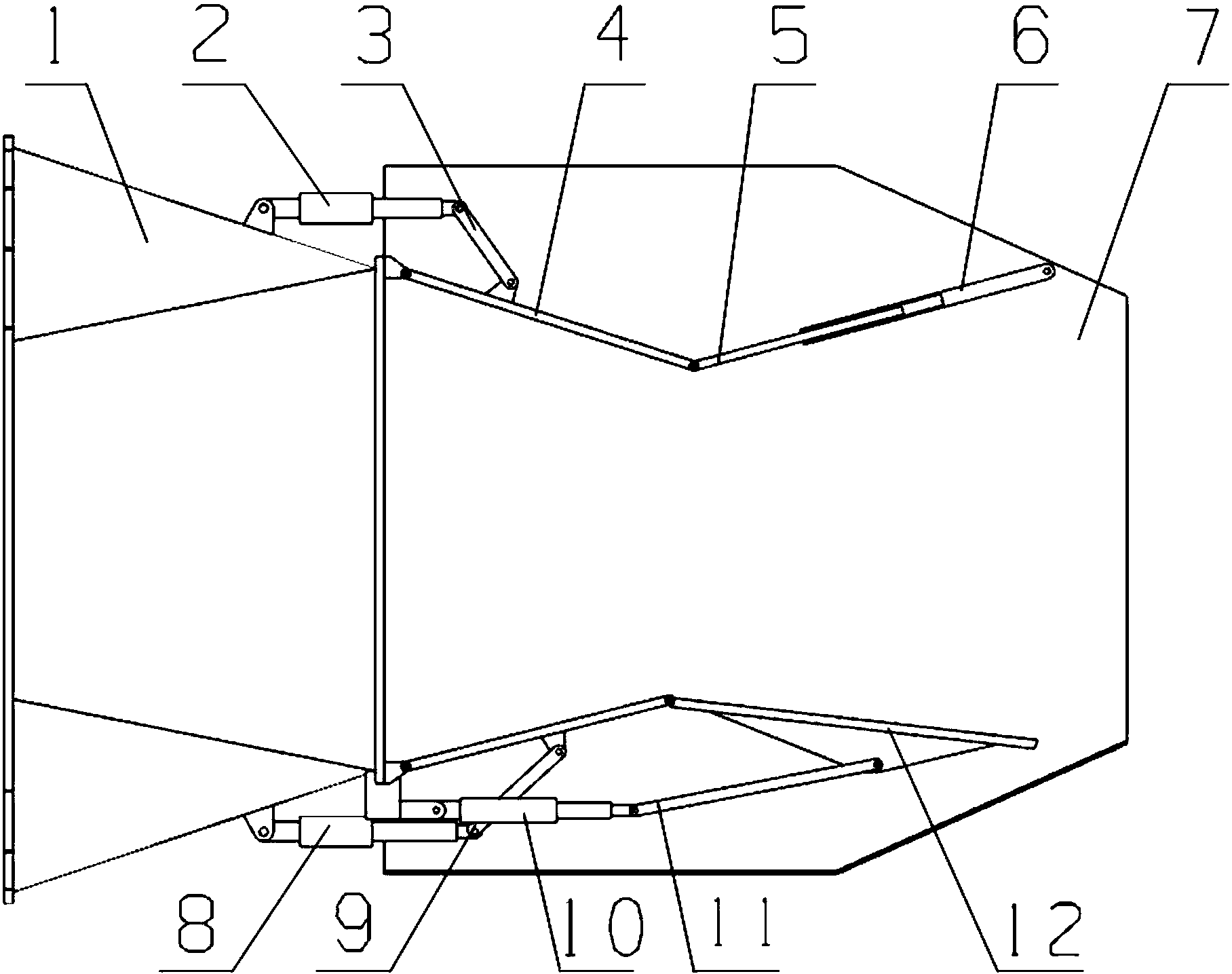

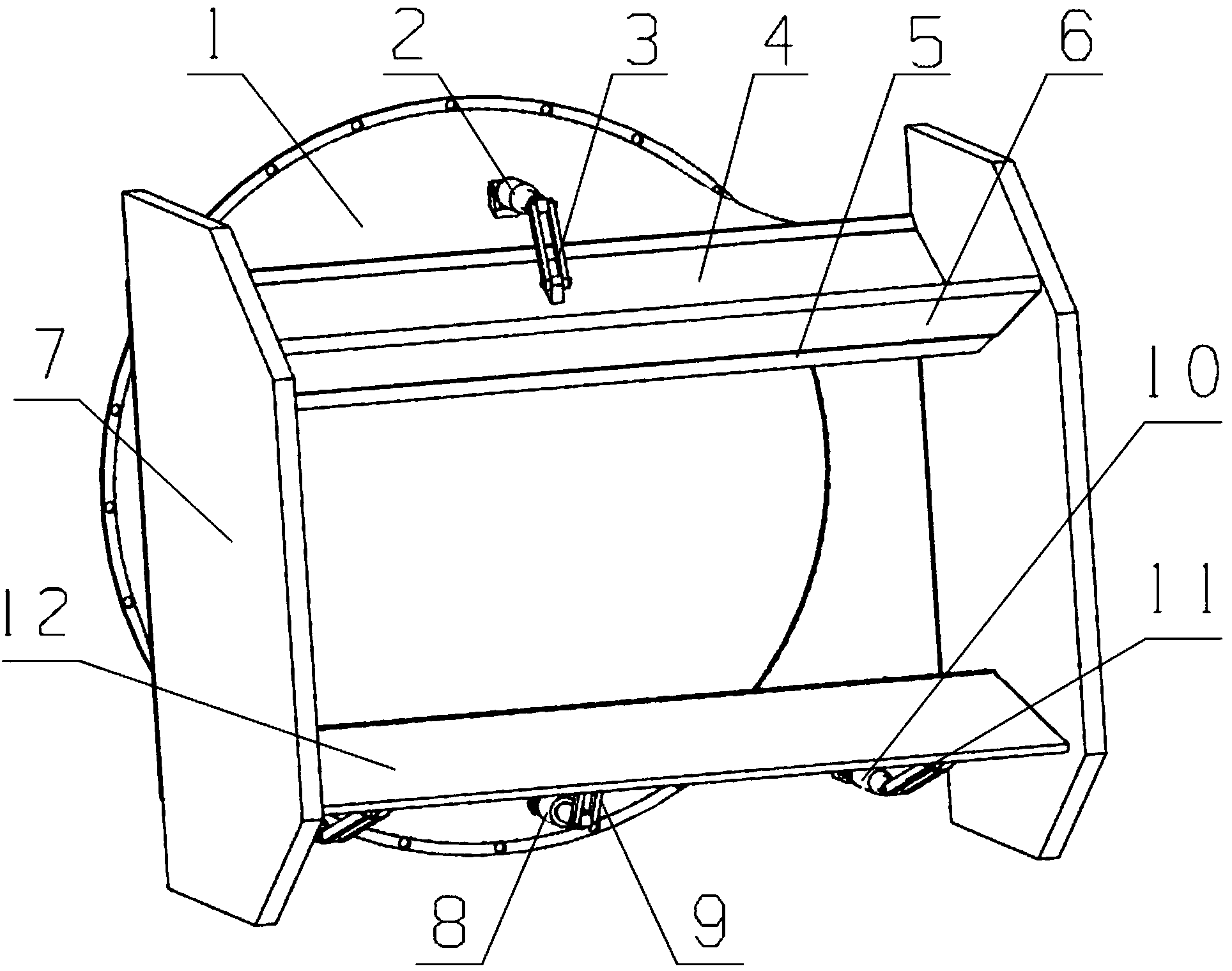

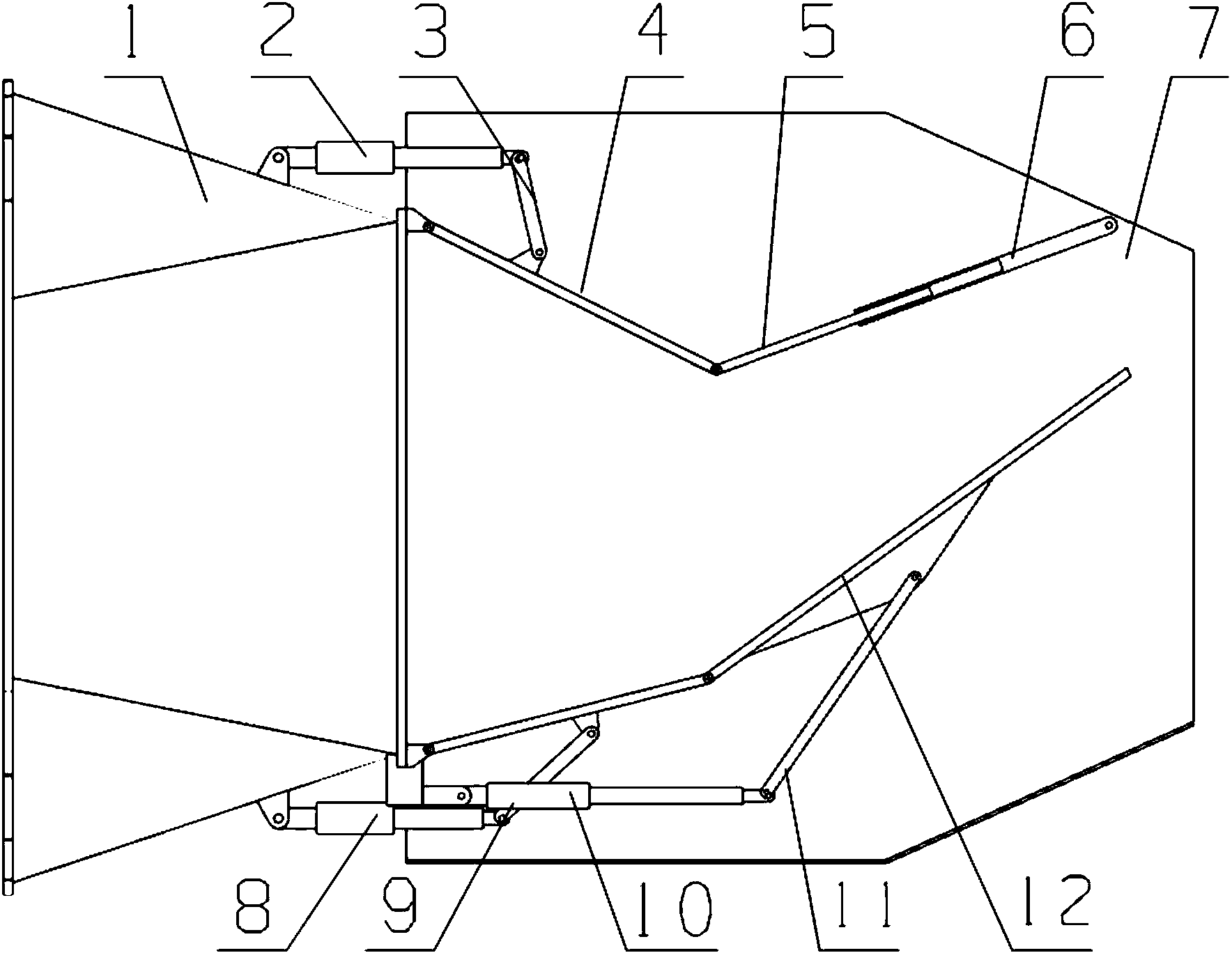

[0026] A binary vector nozzle capable of realizing the S-bend shielding function, mainly composed of a round-to-square cylinder 1, a throat adjustment mechanism, an expansion section adjustment mechanism, a side wall 7, and an outer cover 13, specifically:

[0027] The front end of the circular cylinder body 1 is connected with the engine as the supporting member of the whole nozzle.

[0028] The throat regulating mechanism is mainly composed of an actuator 2, a pull rod 3, a convergence adjustment plate 4, an actuator 8 and a pull rod 9. Among them, the front end of the actuator 2 is connected to the outer wall of the circular cylinder 1 through a mechanical connection, and the other end is connected to the pull rod 3 through the rotation pair; the pull rod 3 is connected to the outer front section of the convergence adjustment plate 4 through the rotation pair; the convergence adjustment plate 4 It is connected to the installation side of the circular cylinder body through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com