S-shaped binary spraying pipe having vector deflection function

A binary nozzle and function technology, applied in jet propulsion devices, machines/engines, etc., can solve problems such as poor stealth effect, inability to meet nozzle outlet area adjustment and vector deflection functions, and low infrared radiation intensity values of engines. , to achieve the effect of high reliability, good infrared stealth performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

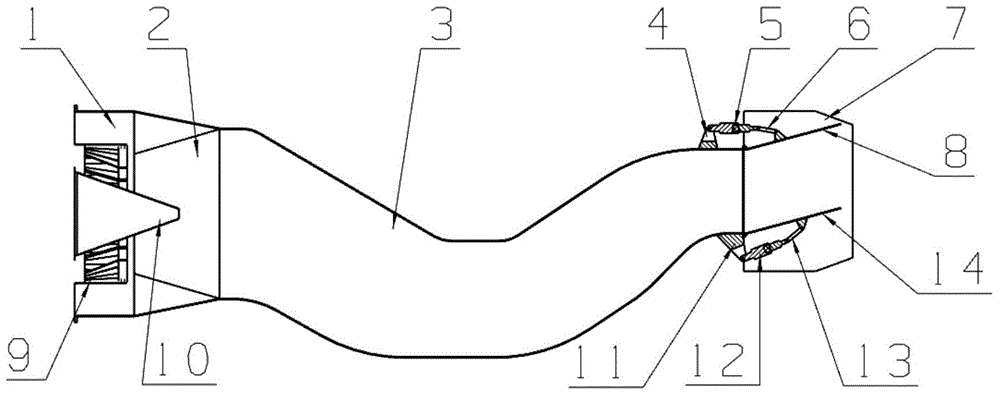

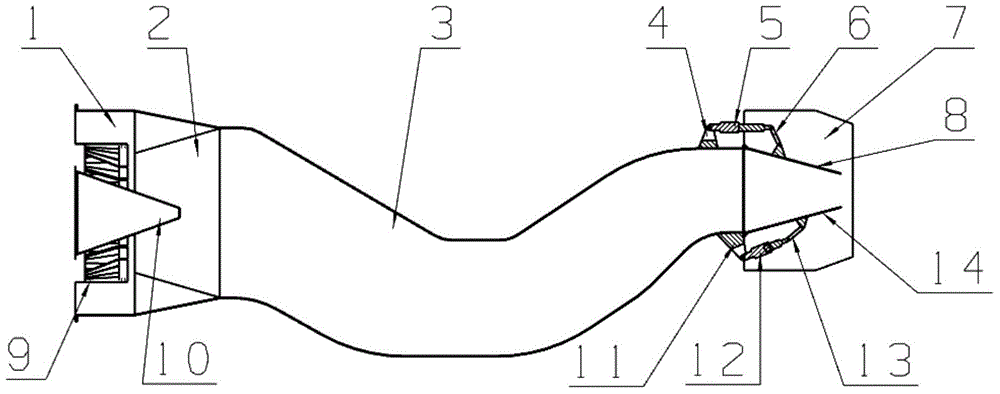

[0030] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

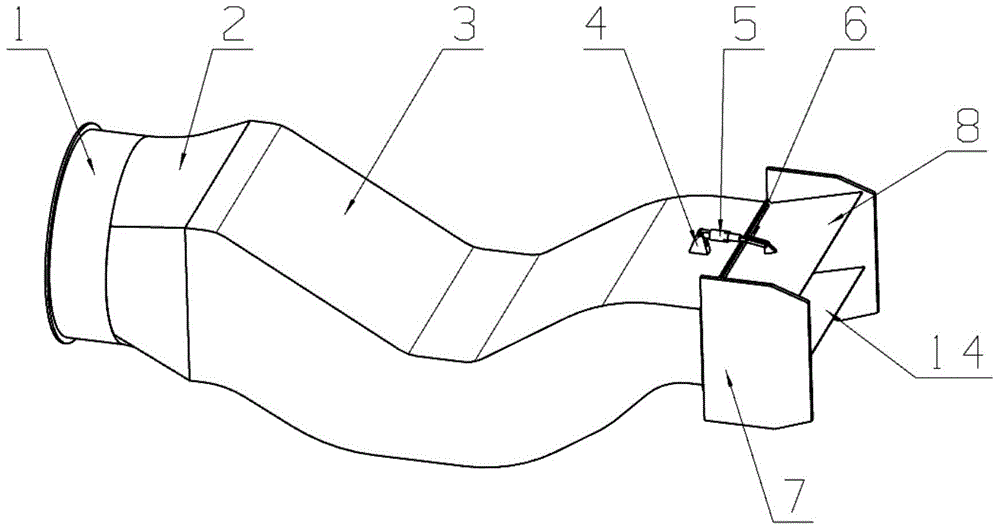

[0031] Such as Figure 1 to Figure 3 As shown, the present invention provides an S-curved binary nozzle with a vector deflection function, including a cylindrical body 1 , a circular square 2 , an S-curved body 3 , a nozzle outlet adjustment mechanism and a side wall 7 .

[0032] The front end of the cylinder body 1 is connected with the engine as a supporting member for the entire nozzle.

[0033] The rounded square 2 (also the cylinder body) is the transition section between the circular section and the rectangular rounded section. The front end of the rounded square 2 is sealed with the rear end of the cylindrical barrel 1, and the rear end of the rounded square 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com