Three-way pressure compensator assembly

A three-way pressure and compensator technology, which is used in fluid pressure actuation devices, fluid pressure actuation system components, servo motor components, etc. Problems such as the working performance of the main engine, to achieve the effect of stable LS pressure control signal, stable spool movement, and elimination of peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

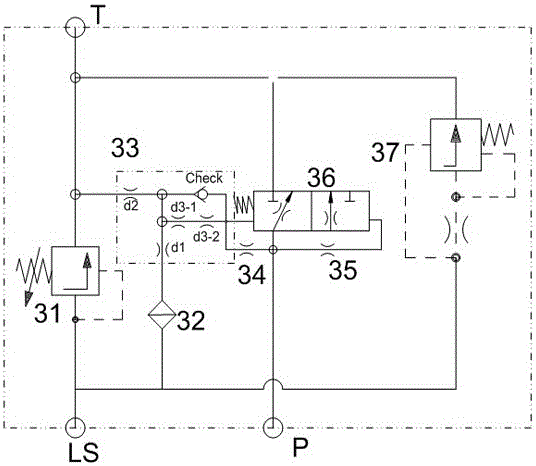

[0021] The hydraulic principle diagram of the present invention is as image 3 as shown, image 3 The three-way pressure compensator assembly shown in the hydraulic system includes LS relief valve 31, filter 32, damping network 33, dynamic damping hole 34, oil inlet damping hole 35, three-way pressure compensator 36 and constant flow valve 37. The above hydraulic components are pressed image 3 The hydraulic schematic connections shown together form the three-way pressure compensator assembly.

[0022] according to image 3 The three-way pressure compensator assembly made in the hydraulic schematic diagram shown includes T port, LS port and P port. There is an LS overflow valve 31 connected between the T port and the LS port, and a connection between the T port and the LS port. There is a constant flow valve 37, and a three-way pressure compensator 36 is connected between the P port and the T port. The three-way pressure compensator 36 has two working positions. When the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com