Sieve net

A technology of screen mesh and slurry is applied in the field of screen mesh for cleaning slurry suspensions to achieve the effect of low expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

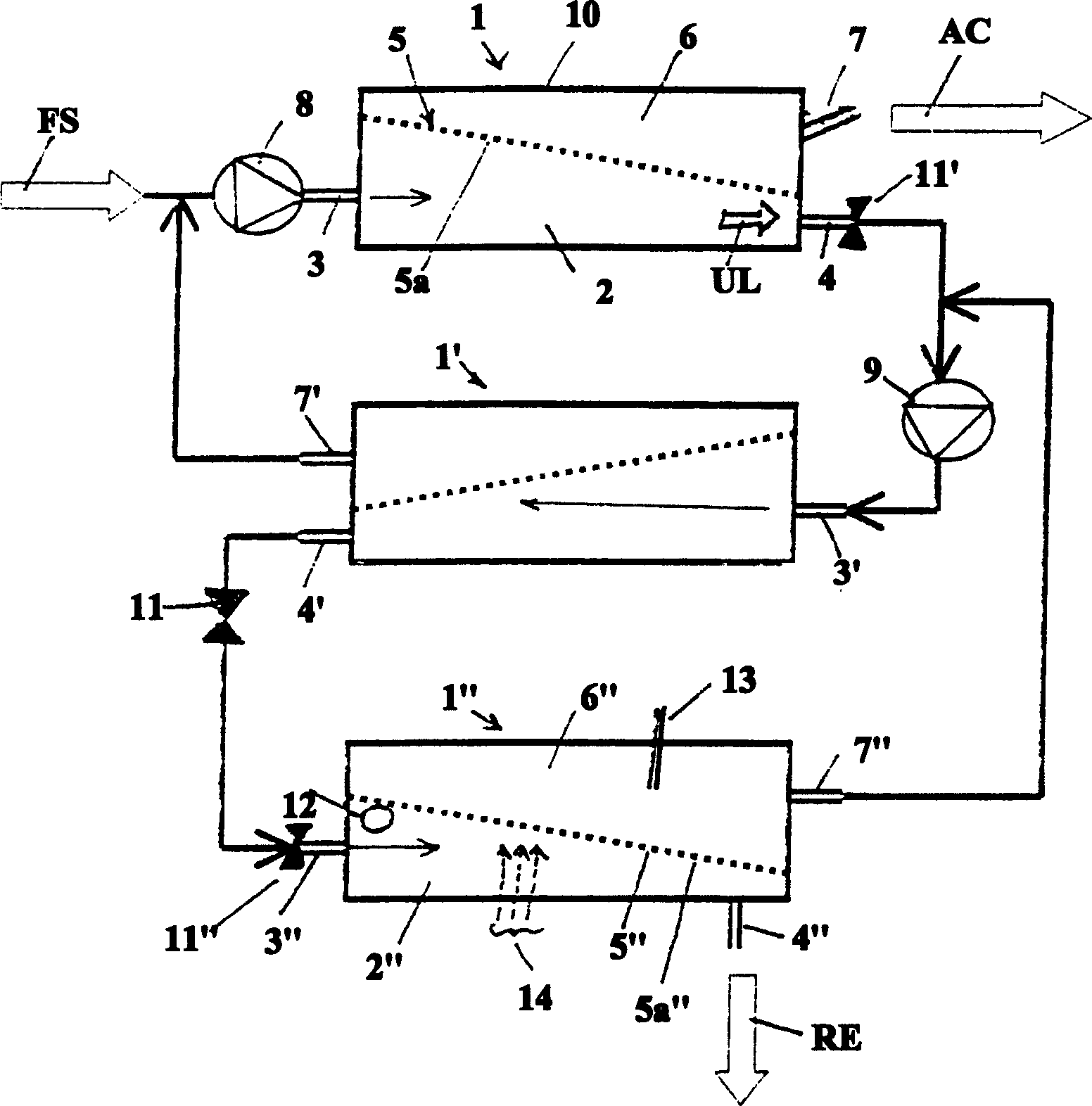

[0044] attached figure 1 A three-stage screening device is shown, using continuously arranged screens 1, 1', 1" according to the invention to clean slurry suspensions. These three screens are of similar design, which will 1. The screen 1 for cleaning the slurry suspension FS has a separation chamber 2 delimited by a housing 10 with a slurry suspension inlet 3 and a reject outlet 4. The slurry suspension FS is delivered to the separation chamber 2 by the pump 8 through the slurry suspension inlet 3. In the separation chamber 2, through a partition wall 5 with a screen structure 5a, one with a pointing The receiving chamber 6 of the upper receiving outlet 7 is separated from the slurry suspension inlet 3 and the waste outlet 4. The partition wall 5 asymmetrically separates the separation chamber 2. The slurry suspension high-speed flow onto the screen structure 5a, where part of the suspension is squeezed through the screen structure 5a and is separated in the process, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com