Tactile reproduction device and tactile reproduction method based on two-way friction force control

A technology of tactile reproduction and friction, which is applied in the input/output of user/computer interaction, computer components, graphic reading, etc., can solve the problems of narrow control range of friction coefficient and inability to effectively realize tactile reproduction, etc., and achieve rich Effect of CoF Rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

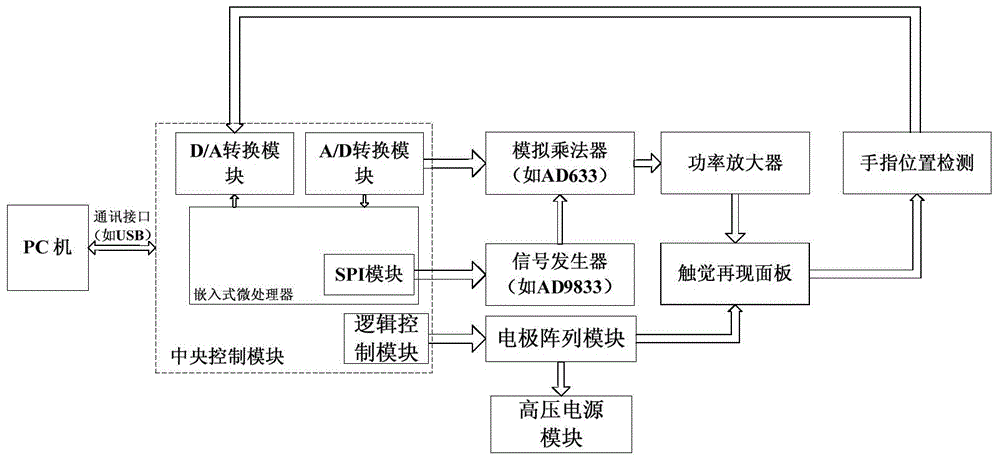

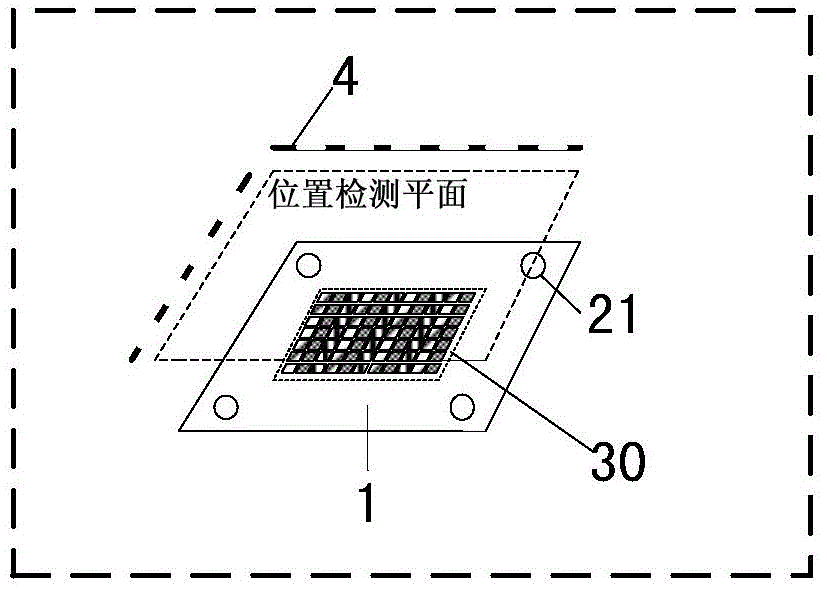

[0036] Such as figure 1 , figure 2 As shown, the tactile reproduction device involved in the present invention adopts the combination of the two principles of the air pressure film effect and the electro-vibration effect to realize the comprehensive control of the friction force, and then realize the tactile reproduction based on the two-way friction force control. The structural schematic diagram of the whole tactile reproduction device is as follows: figure 1 shown.

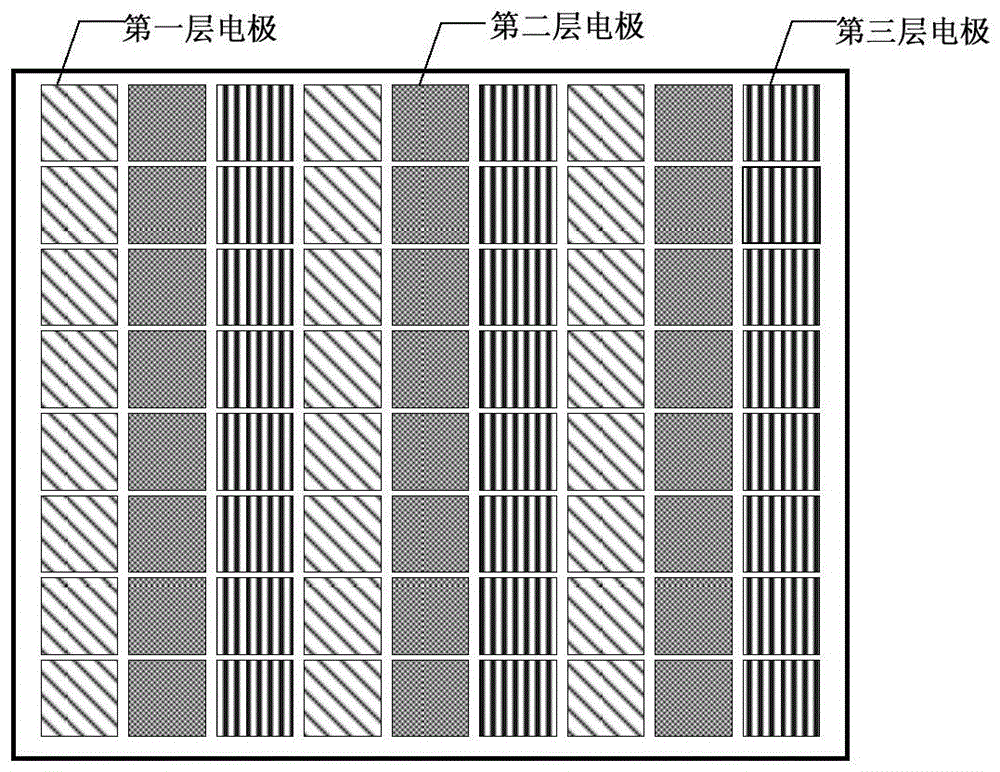

[0037] The device mainly includes the following key components: a tactile reproduction module, a piezoelectric ceramic excitation module, a central control module, an electrode array excitation module, a finger position detection module, and a communication interface module; the tactile reproduction module includes a rigid tactile panel, a piezoelectric An electric ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com