A two-component glue coating equipment

A technology of gluing and equipment, which is applied in coatings, devices for coating liquid on the surface, spraying devices, etc., can solve the problems of easy-mixing failure, low mixing precision, and difficult adjustment of mixing ratio, etc., and achieve high resistance to colloids The effect of impurity ability, mature and reliable control performance, and high flow recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

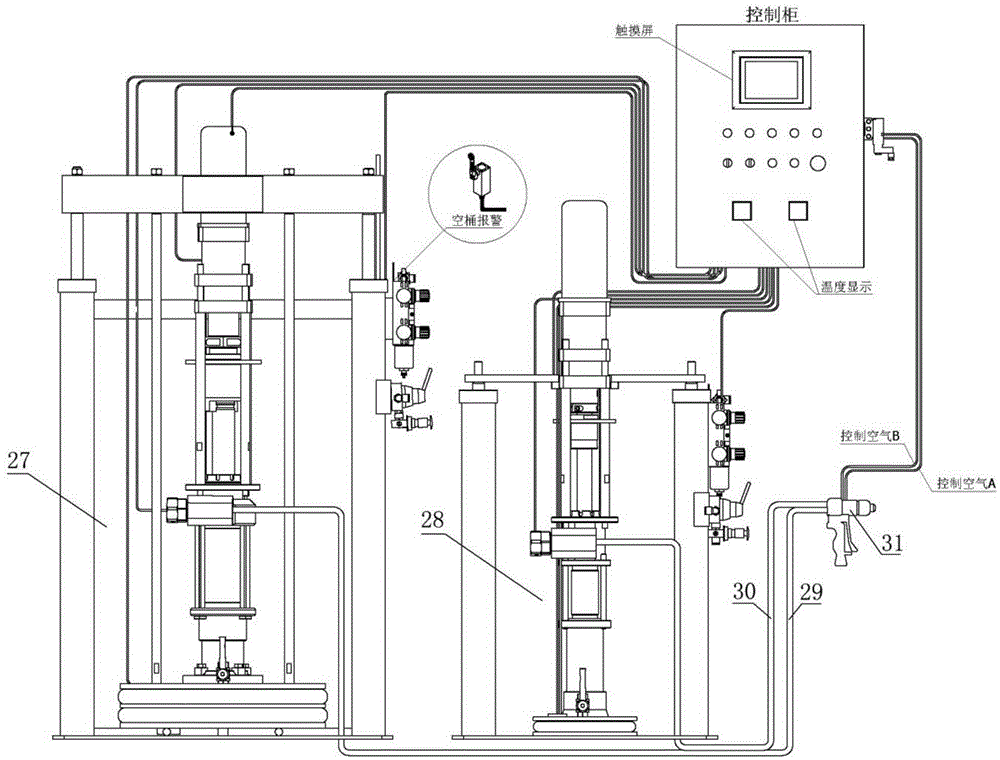

[0039] as attached figure 1 As shown, the two-component gluing equipment of the present embodiment includes A component plunger pump 27 and B component plunger pump 28, and the discharge of the A component plunger pump 27 and B component plunger pump 28 The ports are respectively connected to the A component delivery pipe 29 and the B component delivery pipe 30, and the other ends of the A component delivery pipe 29 and the B component delivery pipe 30 are connected to the glue mixer 31,

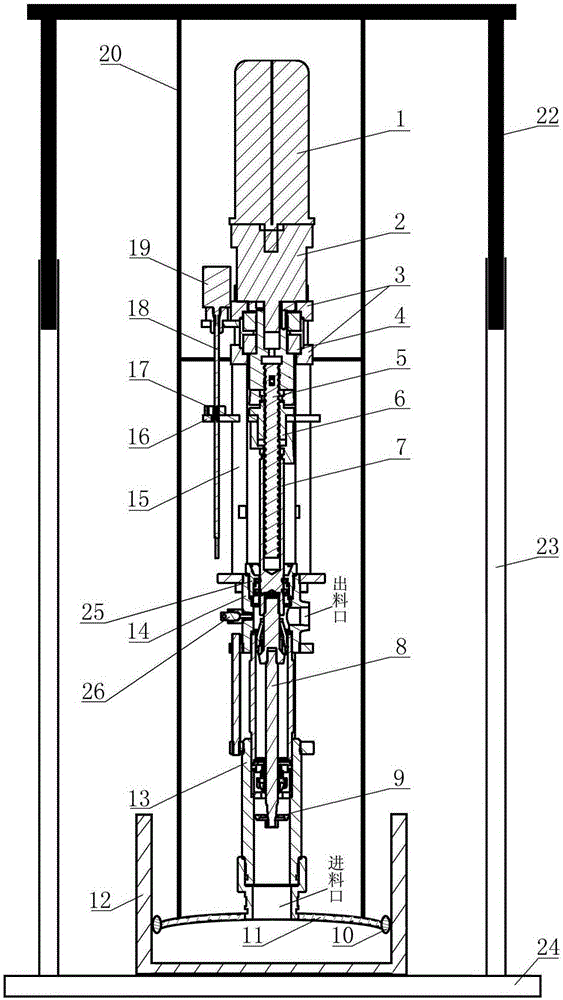

[0040] as attached figure 2 As shown, the aforementioned A-component plunger pump 27 and B-component plunger pump 28 are both electric metering plunger pumps, and the electric metering plunger pump includes a connecting plate 3 and a reducer 2 arranged above the connecting plate 3, so A stepping motor 1 is connected above the reducer 2, and a coupling 4, a screw 5, a screw nut pair 6, a transmission rod 7 and a metering pump are connected in sequence below the reducer 2, and the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com