Device and method for measuring gear meshing backlash through electrical noise

A meshing side and gear technology, which is applied in the field of space low-speed pointing mechanism testing, can solve the problems of no longer having the conditions for disassembly inspection or installation of corner test equipment, powerlessness, and small modulus of high-precision gears, so as to avoid disassembly of the tested equipment The effect of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

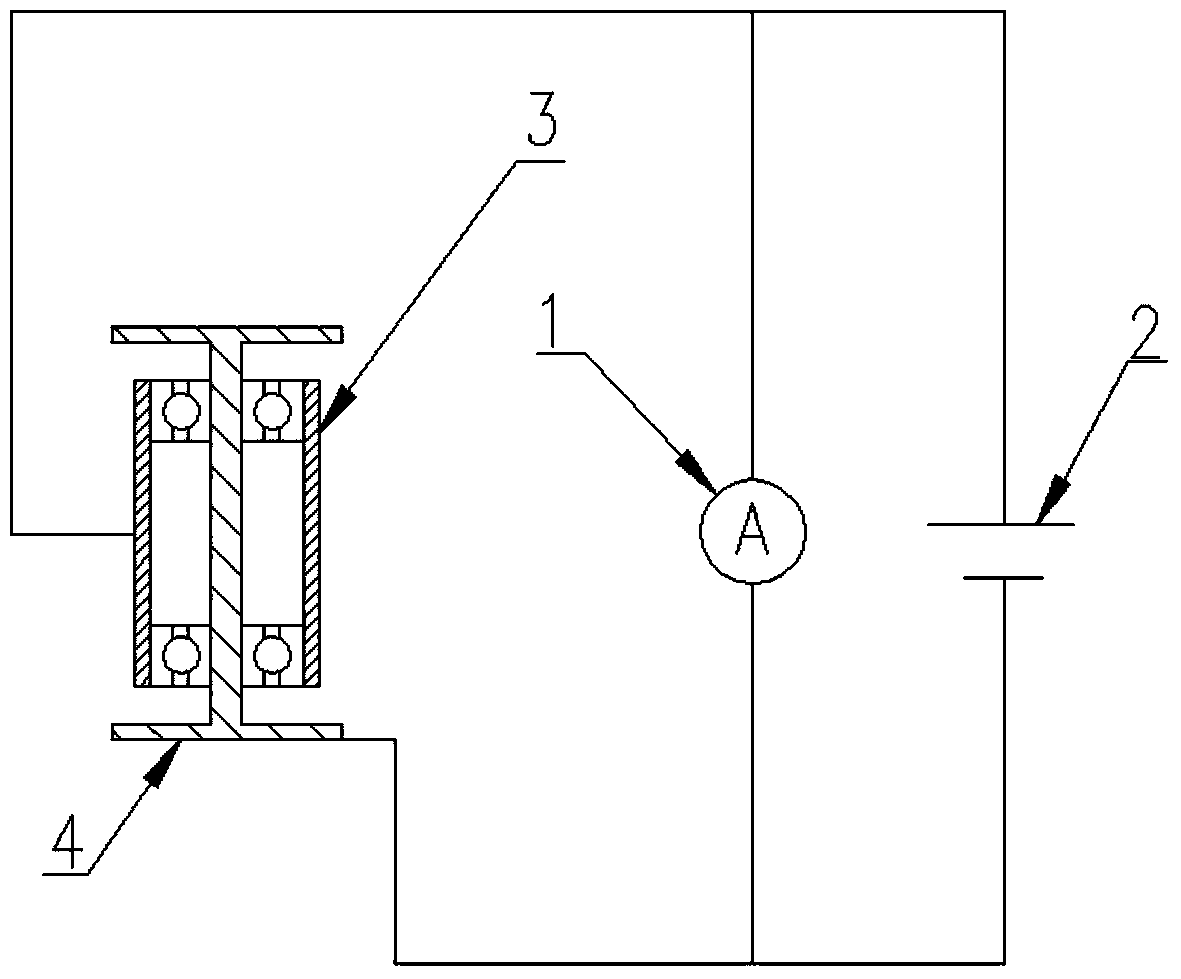

[0019] like figure 1 As shown, a device for measuring gear meshing backlash by using electrical noise, the device includes a noise tester 1, a DC power supply 2 and a gear transmission assembly under test;

[0020] The fixed part 3 of the gear transmission assembly under test is connected to the positive pole of the DC power supply 2 through a wire, and the rotating part 4 of the gear transmission assembly under test is connected to the negative pole of the DC power supply 2 through a wire;

[0021] The fixed part 3 of the gear transmission assembly under test is connected to the positive pole of the noise tester 1 through wires, and the rotating part 4 of the gear transmission assembly under test is connected to the negative pole of the noise tester 1 through wires.

[0022] The aforementioned noise tester 1 has an AC root mean square acquisition mode (AC-rms), and the single-cycle acquisition time is a parameter that needs to be set, which is related to the rated speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com