A mosaic automatic puzzle machine and mosaic puzzle method

A mosaic and automatic technology, applied in decorative arts, decorative structures, etc., can solve the problems of easy error, labor and time, invisible mosaic wall paintings, etc., to achieve the effect of convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

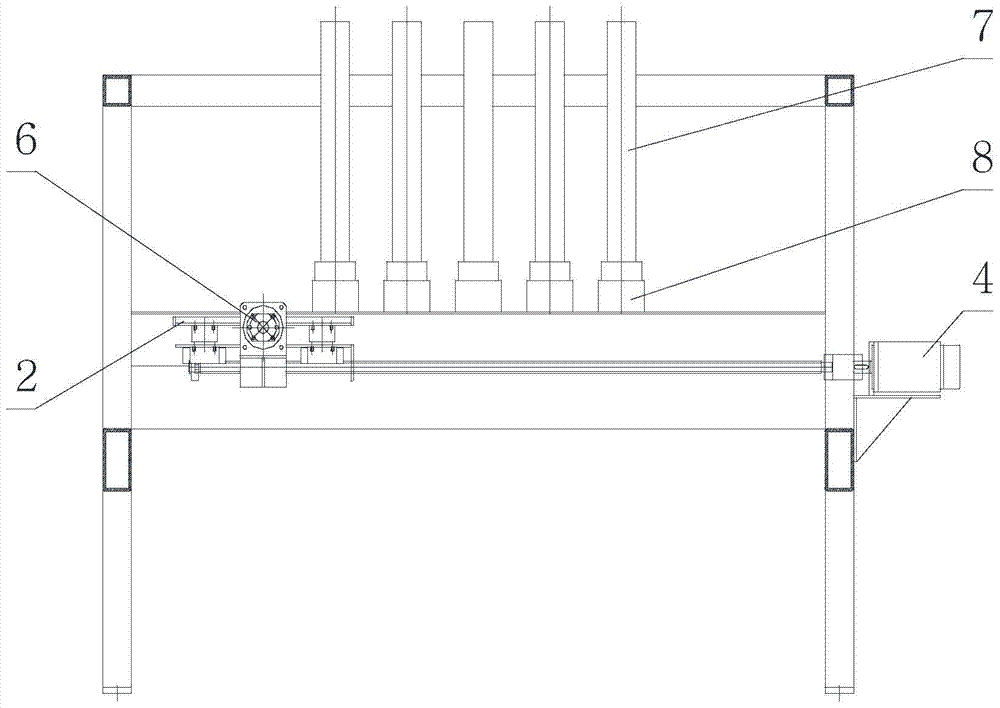

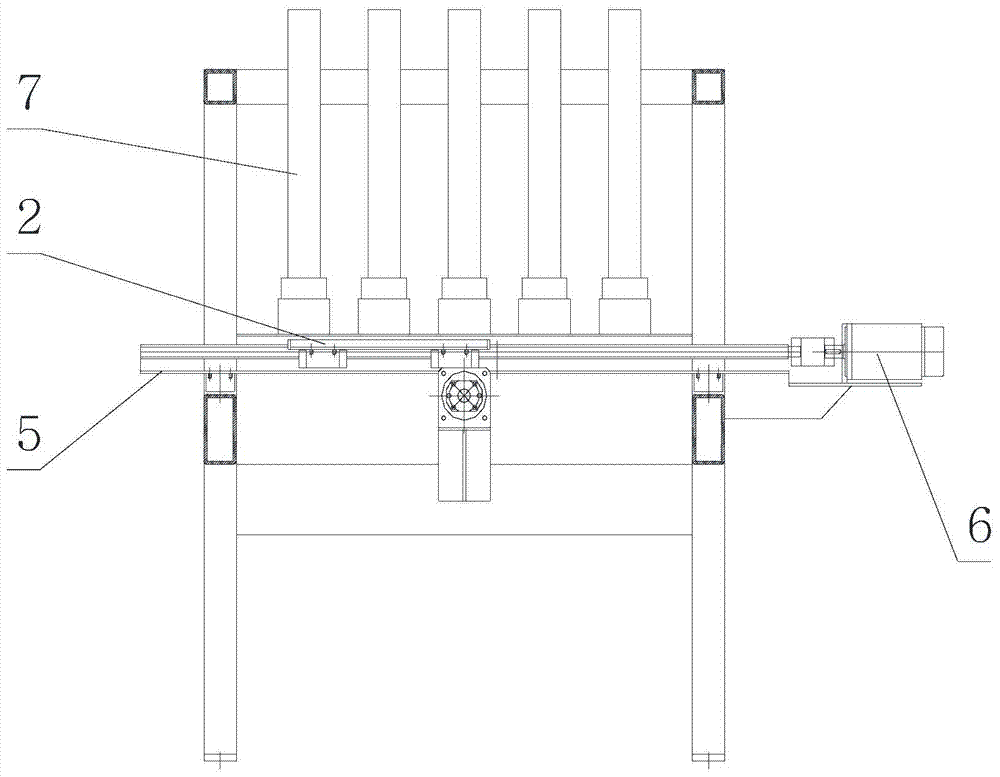

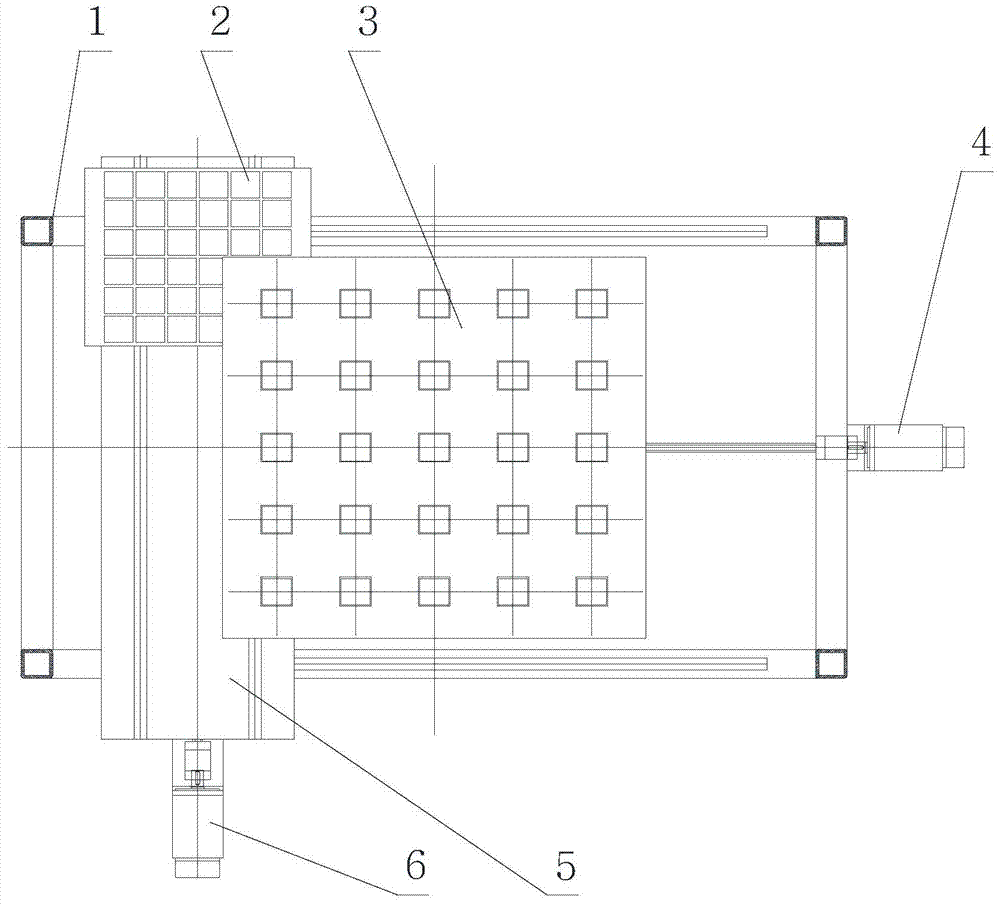

[0037] Such as Figure 1-Figure 3 As shown, the upper part of the frame 1 is a matrix mosaic warehouse 3, which is composed of a plurality of columnar and vertically arranged material tubes 7, and each material tube 7 is stacked together with the same specification and color number mosaic single particles. The material tube and the material tube are arranged in a matrix, which is convenient to realize accurate mobile positioning.

[0038] Under the matrix mosaic warehouse, a release valve 8 is arranged. Its function is to release the mosaic single particles in a certain material tube corresponding to the matrix mosaic warehouse into the corresponding slot of the template according to the instruction of the control device. Mosaic single grain.

[0039] A horizontal displacement device for the template is arranged under the release valve, including: the translation template 2 and the guide rail 5; the guide rail 5 is in the direction of the Y axis, and the translation template 2 is ...

Embodiment 2

[0046] Such as Figure 1-Figure 3 The upper part of the frame 1 shown is a matrix mosaic warehouse 3, which is composed of a plurality of columnar vertical pipes 7, and each pipe contains mosaic single particles of the same specification and color number stacked together. The material tube and the material tube are arranged in a matrix.

[0047] Under the matrix mosaic warehouse, a release valve 8 is arranged. Its function is to release the mosaic single particles in a certain material tube corresponding to the matrix mosaic warehouse into the corresponding slot of the template according to the instruction of the control device. Mosaic single grain.

[0048] A template horizontal displacement device is arranged below the release valve. The action signal generated by the control device drives the X-axis motor 4 and the Y-axis motor 6, so that the translation template 2 can accurately move a certain distance in the X and Y directions.

[0049] The specific implementation process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com