Roof edge beam, wall panel and roof panel connection structure and modular integrated house

A roof panel and edge beam technology, applied in the direction of roof, roof covering, building components, etc., can solve the problems of cumbersome assembly process, outward warping, water leakage, etc., to speed up assembly efficiency, simplify connection structure, strengthen sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

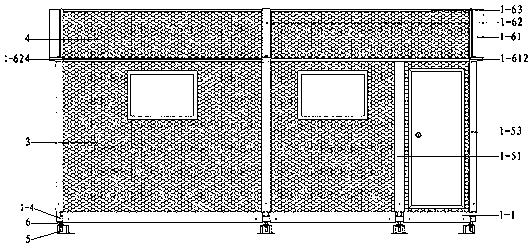

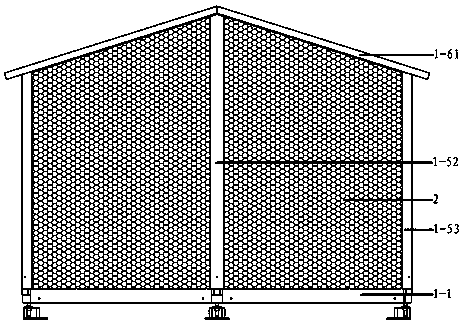

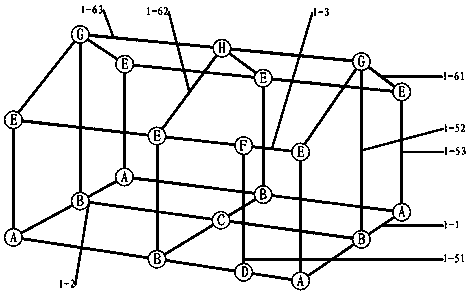

[0031] The embodiment of the modular integrated house of the present invention: as Figure 1 to Figure 3 As shown, the modular integrated house is mainly composed of a house skeleton, gable panels 2, longitudinal wall panels 3, roof panels 4, floors and footings 5. 4 Transition connection is made through the ridge beam to form a structure with a high center and low sides on the roof of the modular integrated house, which includes: two side slopes symmetrically distributed front and back, and each side slope is composed of two roof panels oppositely distributed on the left and right 4. It is formed by the transitional butt joint of the front and rear inclined roof beams, the slopes on both sides are connected by the transitional butt joint of the ridge beams 1-63 extending left and right, and the roof panels 4 on the left and right sides of each side slope are connected by the roof side beams 1-61 On top of gable board 2. Such as Figure 5 As shown, the end of the roof panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com