Direct-reduced iron agglomeration apparatus

A technology of reducing iron powder and pressure, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of difficult pressing and forming in the middle of the roll, increasing the possibility of discontinuous production, and inability to achieve pressing and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement them. The present invention can be embodied in various forms, and is not limited to the following examples.

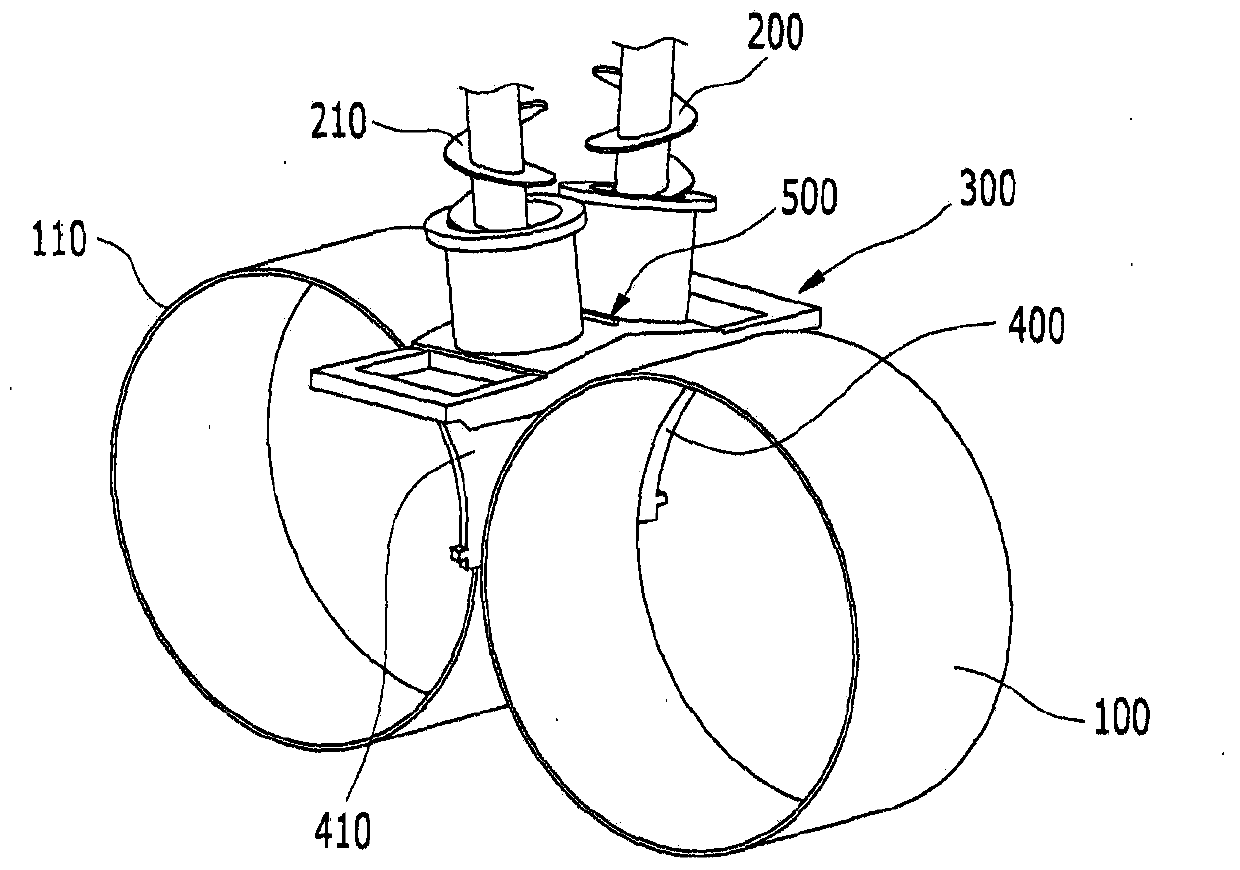

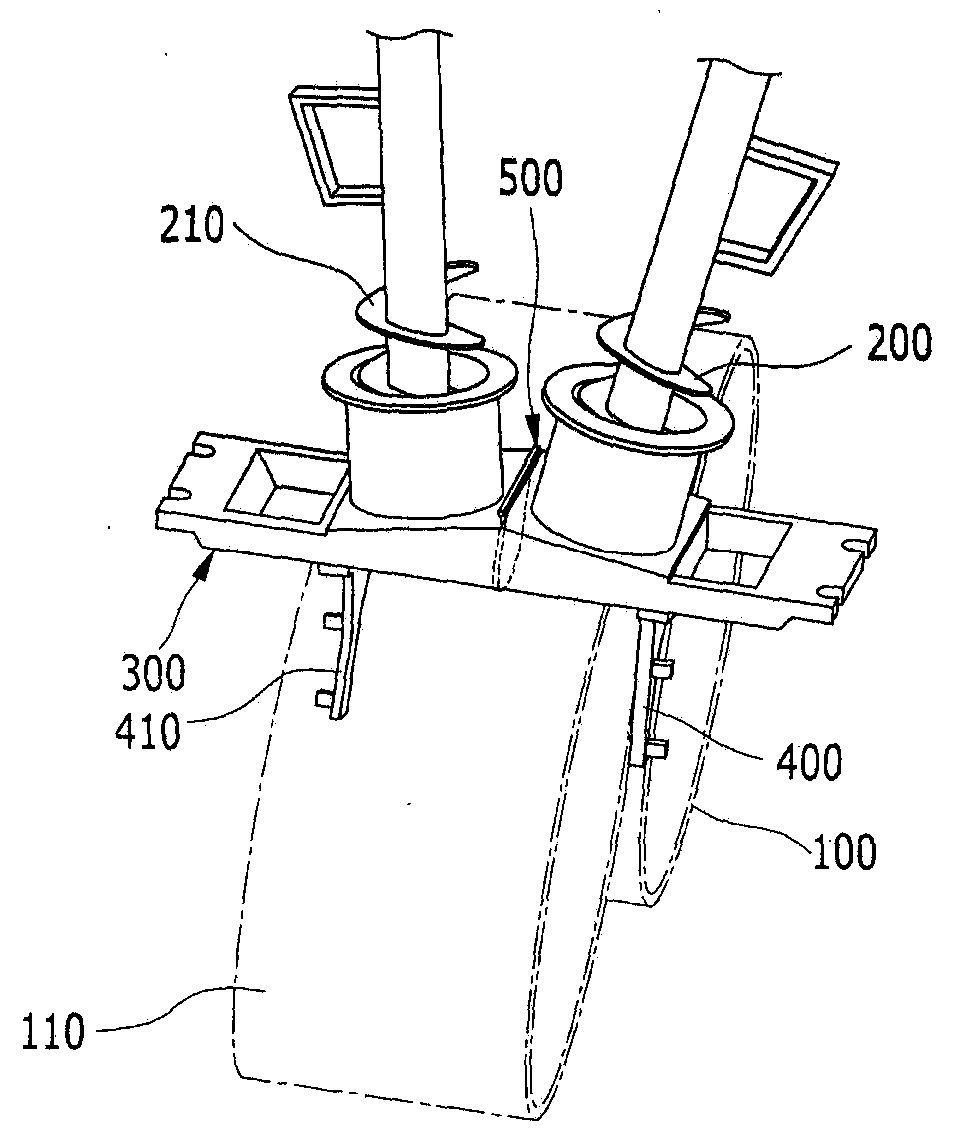

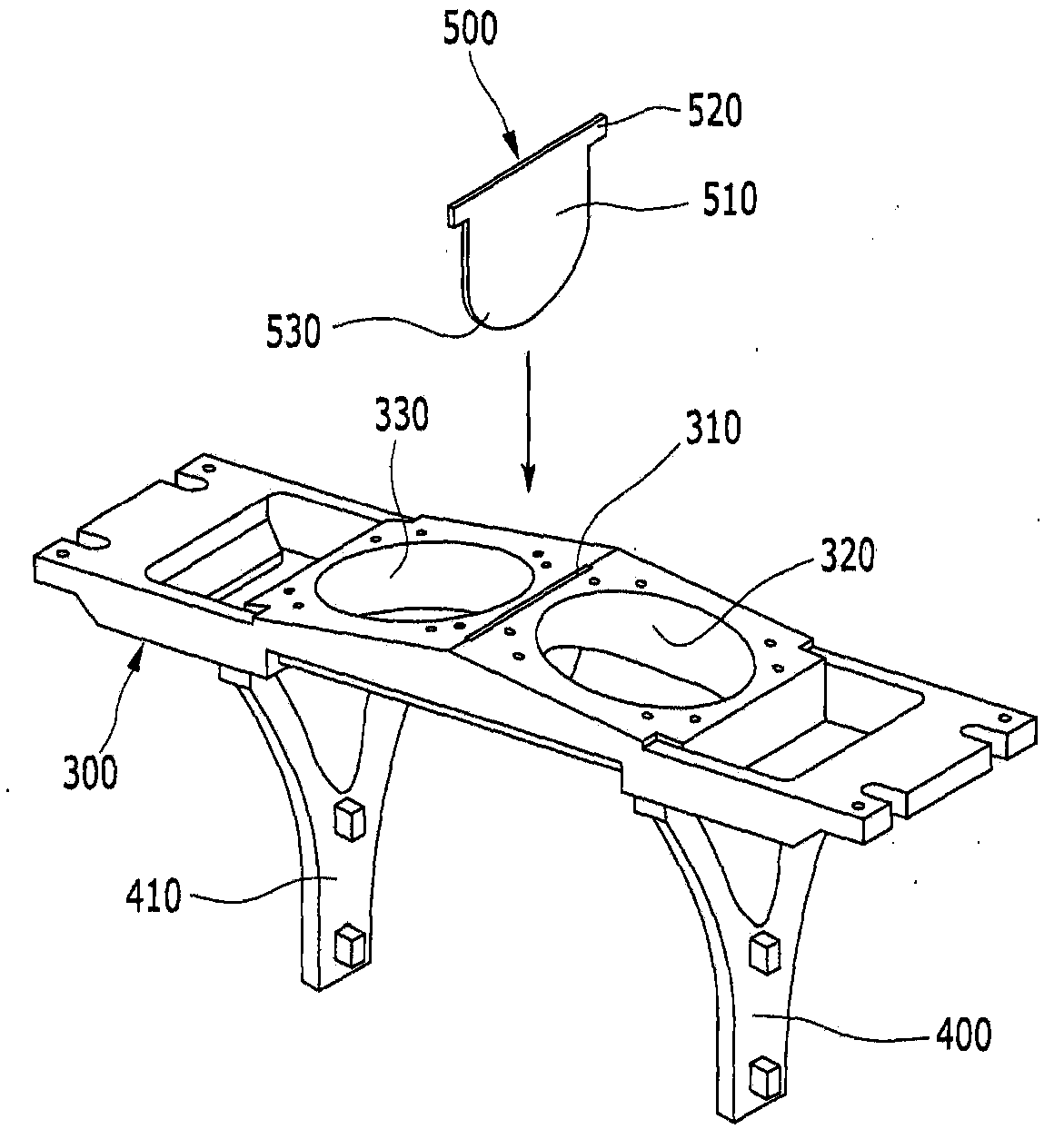

[0042] figure 1 It is a front perspective schematic diagram of a reduced iron powder briquetting device according to an embodiment of the present invention, figure 2 It is a side perspective schematic diagram of a reduced iron powder briquetting device according to an embodiment of the present invention, image 3 It is a partially exploded perspective view of a reduced iron powder briquetting device according to an embodiment of the present invention, Figure 4 It is a partially combined perspective view of a reduced iron powder briquetting device according to an embodiment of the present invention, Figure 5 for Figure 4 stereo bottom view of Image 6 It is a top view of the feed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com