Reciprocating drive mechanism and electrical tool comprising same

一种往复驱动、电动工具的技术,应用在制造工具、轻便机动装置、金属加工设备等方向,能够解决增加平衡配重8、驱动孔7和导杆11磨损、平衡配重8、驱动孔7和导杆11使用寿命降低、扭矩作用大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As used herein, the term "power tool" includes, but is not limited to, a reciprocating saw. Moreover, other types of power tools having the above-mentioned characteristics are also included within the scope of the present invention.

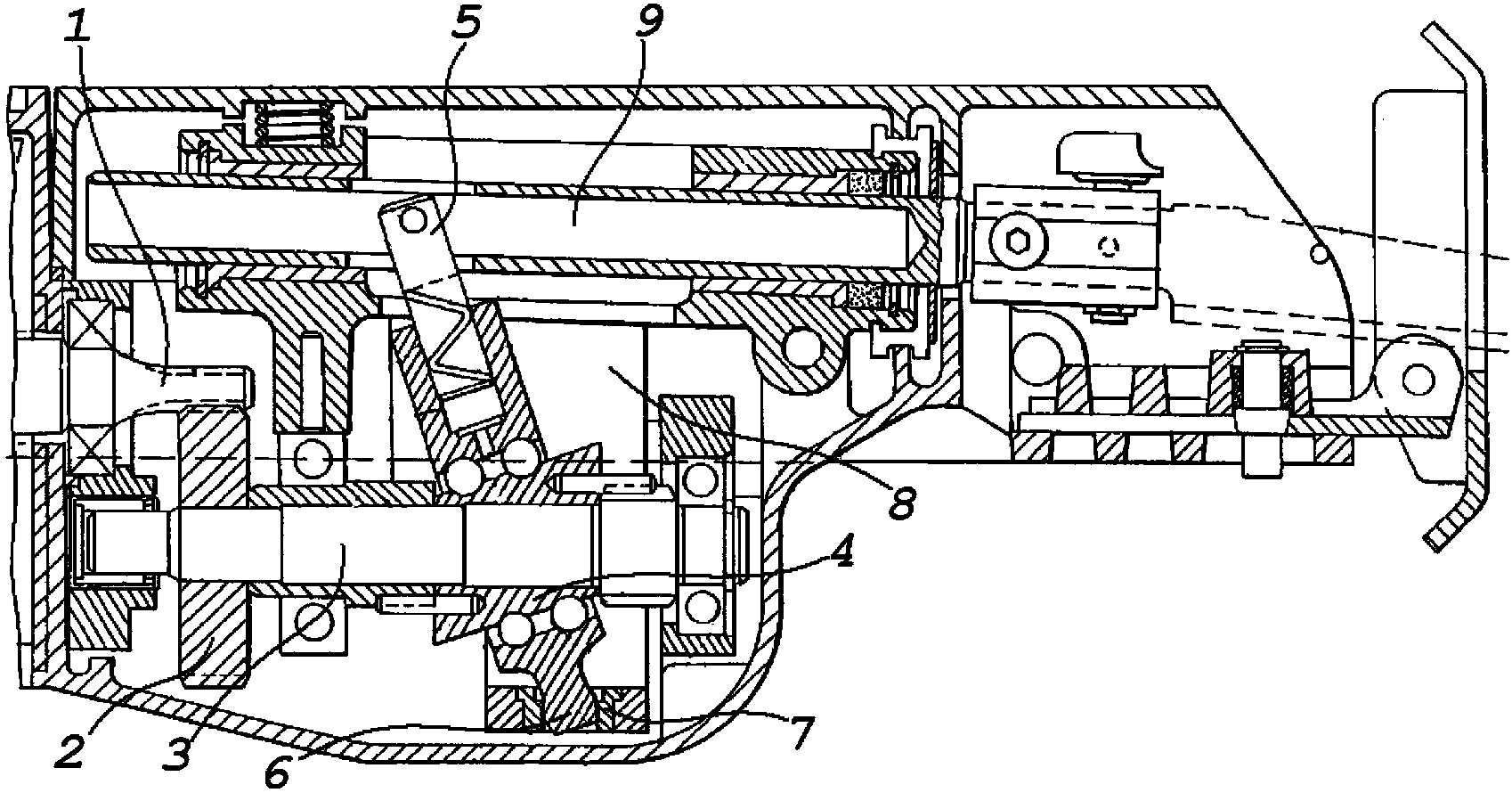

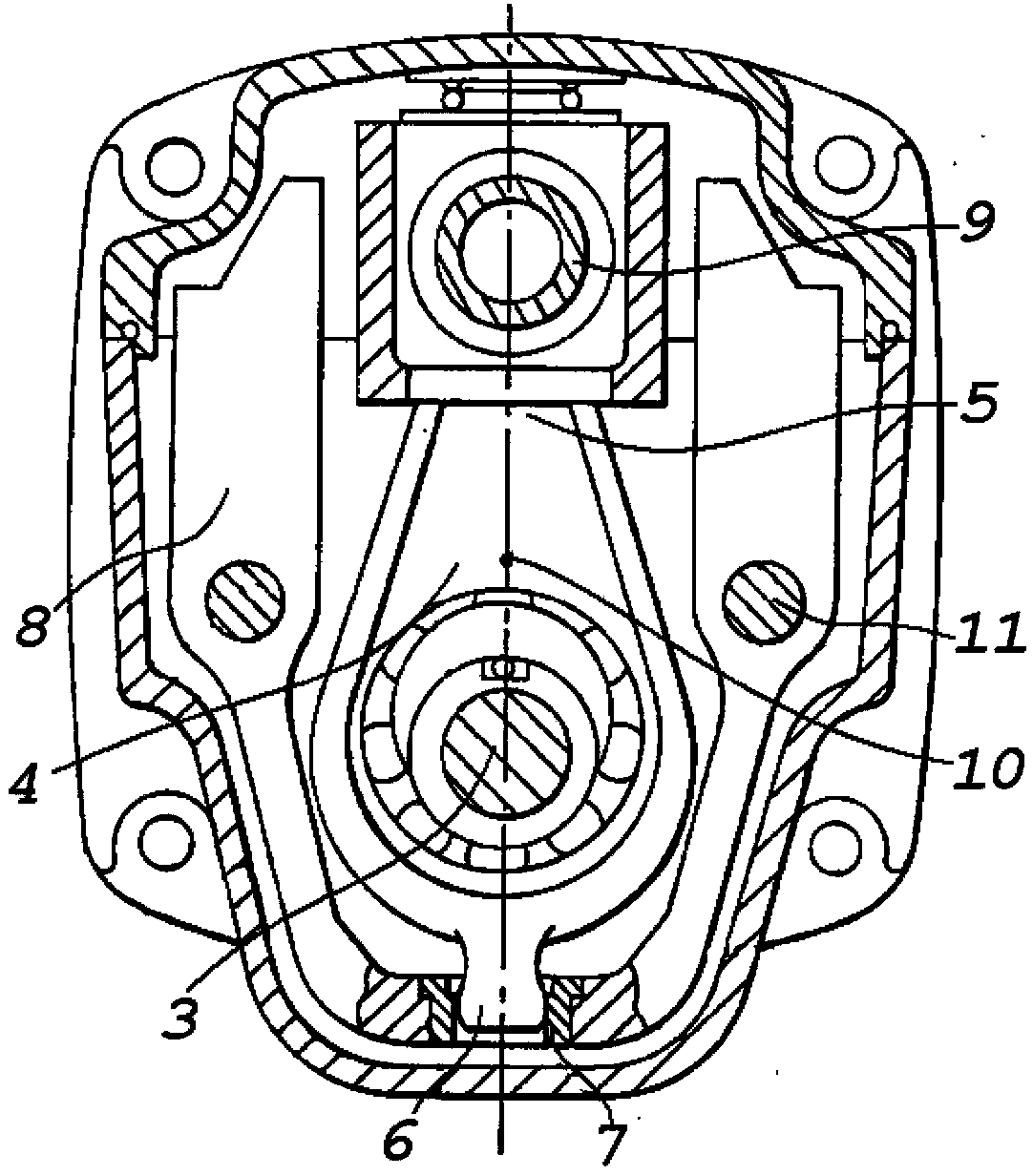

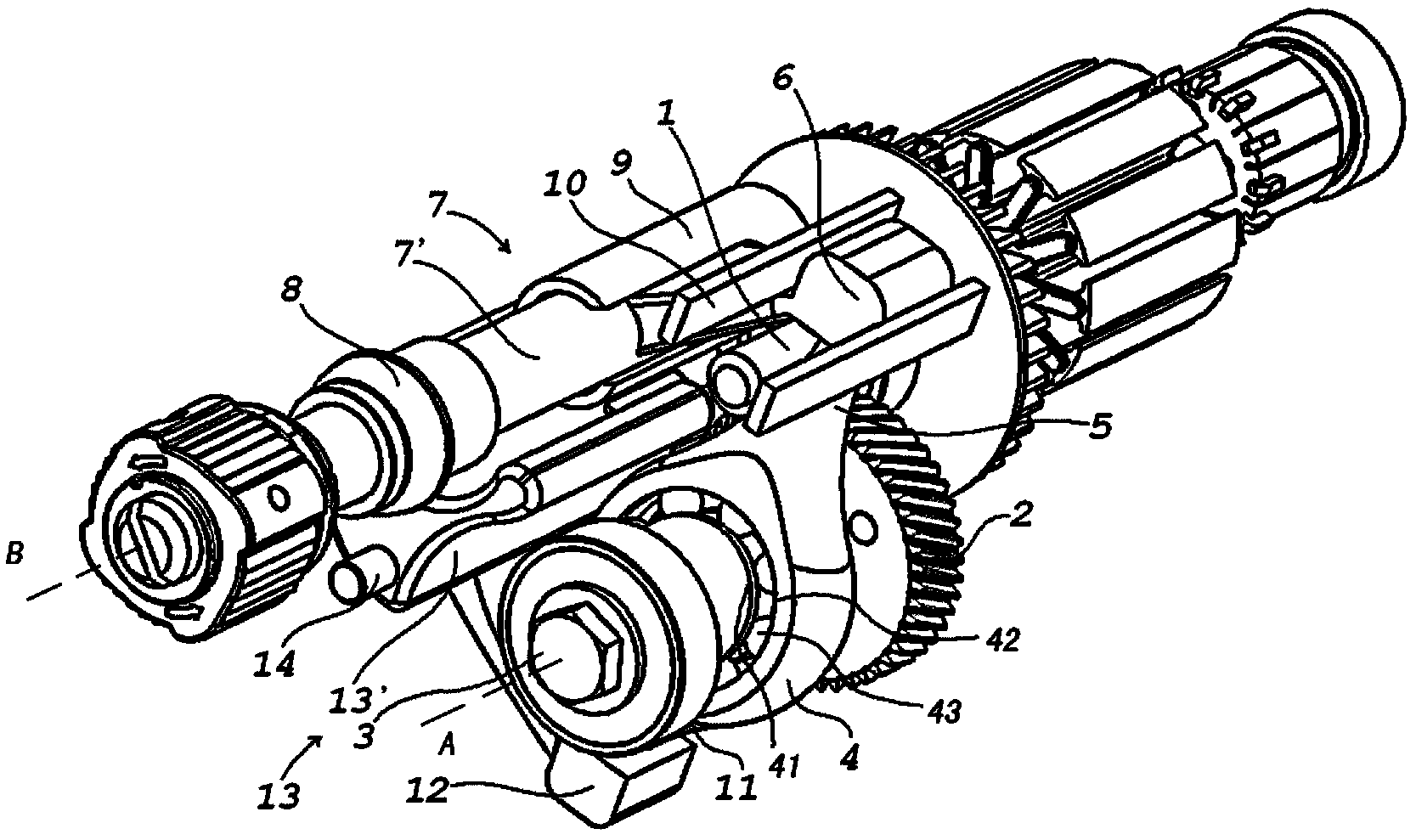

[0023] Oscillating drive reciprocating saw power tools generally include: a drive assembly for powering the cutting operation of the oscillating drive reciprocating saw; a blade clamping assembly for clamping the saw blade to enable reciprocating motion of the saw blade; A reciprocating drive mechanism that converts rotational motion from the drive assembly into reciprocating motion of the saw blade. During the reciprocating motion of the swing-driven reciprocating saw, the reciprocating drive mechanism will produce alternating changes in the direction of motion, which in turn will produce alternating changes in the force, which will cause the swing-driven reciprocating saw to vibrate, which will reduce the vibration of the swing-driven re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com