An aqueous coating composition

A technology of water-based coatings and compositions, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of damaging the coating film, reducing the gloss level of the coating film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0043] Certain embodiments of the present invention will now be described in the following examples, wherein all parts and percentages are by weight unless otherwise indicated. The following materials are used in the examples:

[0044] The DEUTERON MK matting agent from Duteran is based on a 200m 2 / g to 300m 2 / g of polyurea powder with a specific surface area and an average particle size of 6.3 microns.

[0045] ACEMATTTS-100 matting agent from Evonik is a matting agent with 220m 2 / g to 280m 2 / g of fumed silica powder with a specific surface area and an average particle size of 9.5 microns.

[0046] PARALOIDPRD137B emulsion (solids content: 40 wt %) obtained from The Dow Chemical Company is based on 2 / g to 1.5m 2 / g specific surface area and 5.5 micron average particle size, polyacrylate used as matting agent.

[0047] The ULTRALUBED 860 emulsion (solids content: 60wt%) obtained from Ken Adi Technology Company is based on 2 / g to 1.5m 2 / g specific surface area a...

example (Exs)1 to example 12

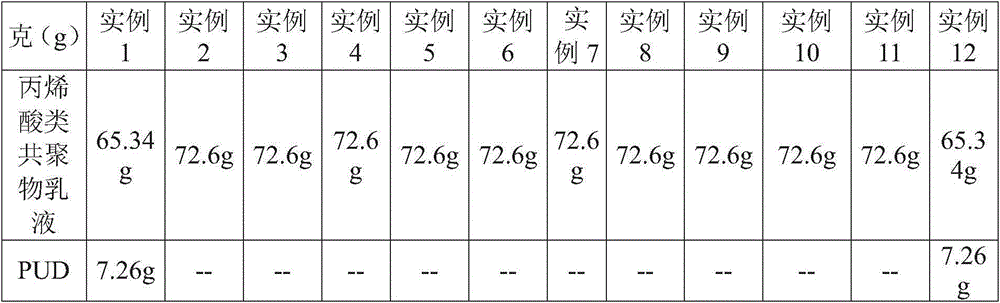

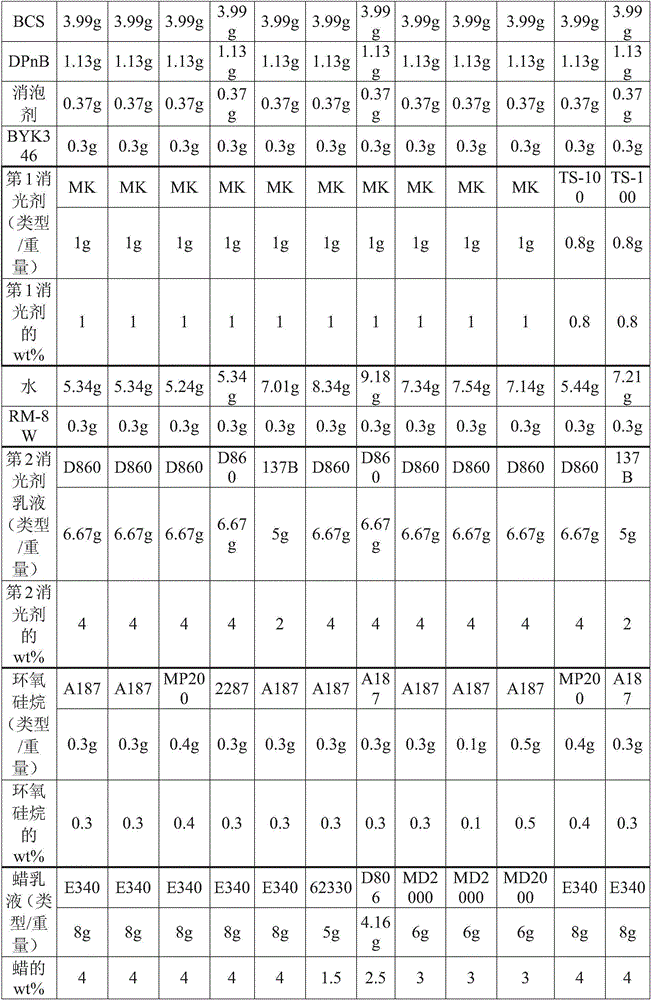

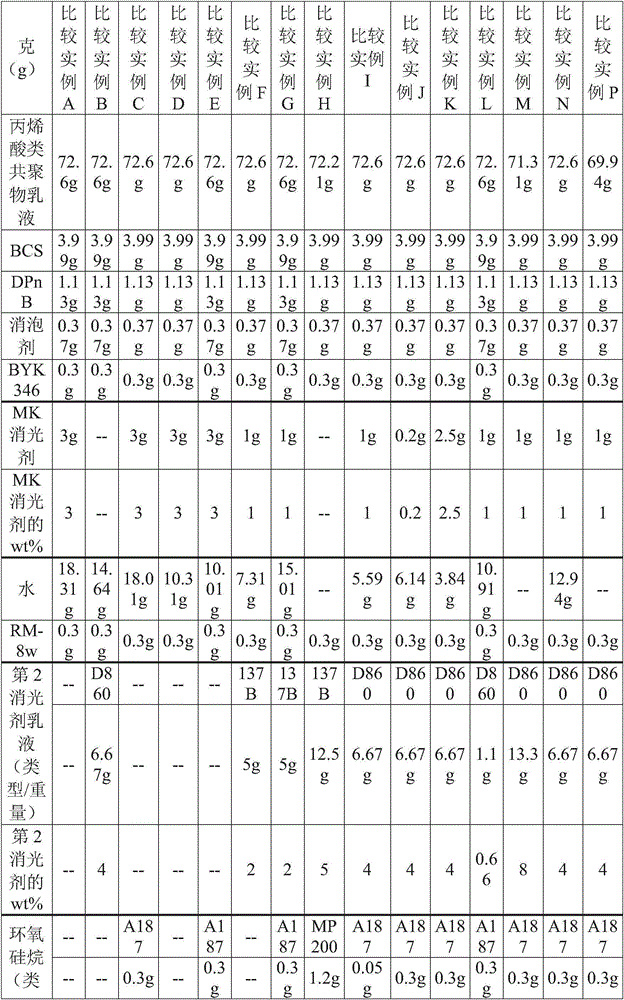

[0096] Coating compositions of Examples 1 to 2 were prepared according to the formulations shown in Table 1. The ingredients listed in Table 1 (below) were mixed using a conventional laboratory mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com